eBook - ePub

Modern Drying Technology, Volume 3

Product Quality and Formulation

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Modern Drying Technology, Volume 3

Product Quality and Formulation

About this book

This five-volume series provides a comprehensive overview of all important aspects of modern drying technology, concentrating on the transfer of cutting-edge research results to industrial use.

Volume 3 discusses how desired properties of foods, biomaterials, active pharmaceutical ingredients, and fragile aerogels can be preserved during drying, and how spray drying and spray fluidized bed processes can be used for particle formation and formulation. Methods for monitoring product quality, such as process analytical technology, and modeling tools, such as Monte Carlo simulations, discrete particle modeling and neural networks, are presented with real examples from industry and academia.

Volume 3 discusses how desired properties of foods, biomaterials, active pharmaceutical ingredients, and fragile aerogels can be preserved during drying, and how spray drying and spray fluidized bed processes can be used for particle formation and formulation. Methods for monitoring product quality, such as process analytical technology, and modeling tools, such as Monte Carlo simulations, discrete particle modeling and neural networks, are presented with real examples from industry and academia.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Modern Drying Technology, Volume 3 by Evangelos Tsotsas, Arun S. Mujumdar, Evangelos Tsotsas,Arun S. Mujumdar in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Chemical & Biochemical Engineering. We have over one million books available in our catalogue for you to explore.

Information

Edition

1Chapter 1

Quality Changes in Food Materials as Influenced by Drying Processes

1.1 Introduction

Drying and dewatering plays a major role in food manufacturing or food processing activities worldwide. Often one of the last operations in the food processing, it controls to a large extent the quality of the final product. Drying is applied to a wide variety of food products, from cereals to finished goods, from raw materials to by-products. The processes used are numerous, according to the type and quantity of product to dry, the amount of water to eliminate, the final desired quality or functionality of the dried product (Tab. 1.1).

Tab. 1.1 Diversity of drying equipment and products in the food industry.

| Equipment | Products |

| Drum dryer | thick liquids, pulps, pastes or slurries: mashed potatoes, carrots, baby cereals, soups, starch |

| Rotary dryer | particulate solid foods: alfalfa, pasta, sugar beet pulp, pomace, starch, whey, pectin residues, lemon pulps, and so on. |

| Deep bed/dihedral dryer | cereals: malt, maize, sunflower grain, rice, wheat |

| Spray dryer | liquids: milk, whey, coffee, tea, yeast |

| Pneumatic dryer | for the finish drying of powders or granulated materials: starch, flour, proteins, distillery residues, aspartame, guar gum, methionine |

| Tunnel conveyor, belt or band dryer | pasta, vegetables, gelatin, fruits, nuts, breakfast flakes, extruded pet foods, soy proteins, tobacco, seeds, and so on. |

| Fluidized bed | powders and small particles: milk powder, whey, yeast, casein, extruded food, coffee beans, soy beans, sunflower beans, chocolate granules, lactose, L-lysine, nutmeg, tomato powder, soy proteins, salt, sugar, and so on. |

| Freeze-dryer | high added-value, heat-sensitive products: coffee extracts, fruits, vegetables, mushrooms, aromatic plants |

| Ventilated cabinets | sausage, ham |

Drying and dewatering impact the mechanical, sensory and nutritional properties of food products, and can be used to create new functionalities (Bonazzi and Bimbenet, 2000, 2008). Drying is one of the main techniques for preserving agricultural and food products; it takes place in the processing of many products, as the main operation or as a consequence of other processing steps. Heat and mass transfer phenomena which are typical of drying also appear during other processes, as in cooking, baking, roasting, smoking, refrigeration, freezing, during storage, and during pneumatic transportation.

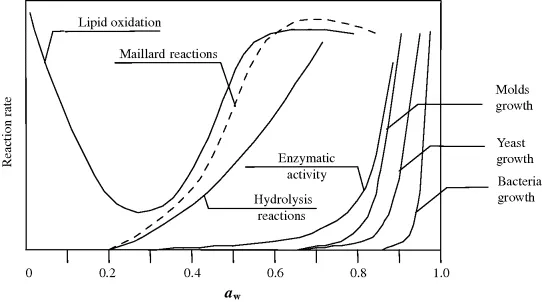

The main objective of drying is to decrease the water activity (aw) of various perishable materials to values <0.5, in order to enable their storage at ambient temperature. The importance of aw in controlling the shelf-life of foods by suppressing the growth of micro-organisms, by reducing the rates of chemical reactions, and by inhibiting enzymatic deterioration is well established. The respective relationships have been summarized by Labuza et al. (1970) in a diagram similar to that of Fig. 1.1.

Water activity is more important to the stability of a food than the total amount of water present, and it makes it possible to develop generalized rules or limits for the stability of foods. For most foods, the critical point below which no micro-organism can grow is in the 0.6–0.7 water activity range. A food product is most stable at its monolayer moisture content, which varies with the chemical composition and structure. Water activity is also useful for predicting the final moisture content at equilibrium versus drying conditions (temperature and relative humidity), and for the selection of ingredients and packaging method. However, limitations of the water activity concept have also been identified. Water activity is defined at equilibrium, whereas foods with low and intermediate moisture content are often complicated, non-equilibrium (supercooled or supersaturated) systems showing time-dependent properties: changes towards equilibrium are observed, physical state and properties evolve during storage, composition and water activity may change with time. Many physical characteristics, such as crystallization, caking, stickiness, collapse, molecular mobility, and diffusivity cannot be fully explained with the water activity concept; corresponding relaxation times must also be taken into consideration.

Fig. 1.1 Water activity and stability diagram of foods.

Furthermore, drying leads to structures usually differing from those of the initial humid product. This can be a disadvantage, but it can also offer a new benefit, as for example the porous structure of mashed potato flakes, crispy granulates for breakfast cereals, instant dry milk powder, and so on. The drying process can, therefore, also be considered as a controlled texturing operation, a source of innovative and easy-to-use products.

In the food industry, drying is applied to many different types of products:

- Low hydrated agricultural products, as a complementary drying for stabilization (corn, rice, wheat, oil seeds etc.)

- Highly hydrated agricultural products, for weight reduction and stabilization, and for absorbing the seasonal character of some productions (milk and by-products, fruits and vegetables, aromatic and medicinal plants, tea leaves, meat, fish, eggs, etc.)

- Intermediate products from industrial processes, for stabilization and conditioning (coffee and tea extracts, pasta, sausages, sugar, etc.)

- Industrial by-products for feed (sugar beet pulps, brewery spent grains, meat or fish meal, whey, etc.)

and it has many purposes:

- Extend the shelf life of foods without the need for refrigerated storage

- Reduce weight and bulk volumes, for saving in the cost of transportation and storage

- Convert perishable products (surplus) to stable forms (e.g., milk powder)

- Produce ingredients and additives for industrial transformation (so-called intermediate food products (IFPs), like vegetables for soups, onions for cooked meats, fruits for cakes, binding agents, aroma, food coloring agents, gel-forming and emulsifying proteins, etc.)

- Obtain particular convenience foods (potato flakes, instant drinks, breakfast cereals, dried fruits for use as snacks, etc.), with rapid reconstitution characteristics and good sensorial qualities, for special use, such as in vending machines, or directly for consumers.

In the present economic context, trade and consumer impose their demand for supply chain, availability, habits, nutritional value, and so on. Dried foods must be processed with the goal of maintaining their quality, such as flavor, texture, convenience, and functionality, increasing their nutritional content, and reducing anti-nutritional factors or toxins. Frequently, there is an extreme focus of food processing on maintaining the bioactivity and structural functionality of the product (Rahman, 2005). This situation imposes constraints on the food industry with regard to the production and selection of raw materials, and the choice of equipment, depending on the products. As an example, the vending machines for hot drinks must deliver automatically powders with constant flowability and composition, good dosage properties, and good solubility. Quality is a relative property and it is, therefore, important to define the expected properties from the consumer's point of view (Tab. 1.2) in order to be able to link possible spoiling or modifications to the relevant process parameters.

Tab. 1.2 Examples of different aspects of dried product quality from the consumer's point of view.

| Appearance | Color, brightness |

| (dried/rehydrated) | Shape or aspect (big particles, powder) |

| “Natural” looking | |

| Taste | Taste itself |

| (dried/rehydrated) | Aroma |

| Texture | |

| Ease of use | Rehydration or dissolving rate (cold or hot water) |

| Apparent density (variation for proportioning) | |

| Stability over time | |

| Packaging enabling use and re-use of the product without any quality loss | |

| No agglomeration or sticking to the packaging | |

| Special properties | For example, for pasta: no breakage during storage, short cooking time |

| Composition | Reproducibility |

| Additives: origin and concentration | |

| Energetic value (calories), fat content, vitamins, and so on. | |

| No allergens | |

| No nitrate or pesticide residuals | |

| Law, GMO, and so on. | |

| Microbiology | Limited number of micro-organisms with absence of pathogens |

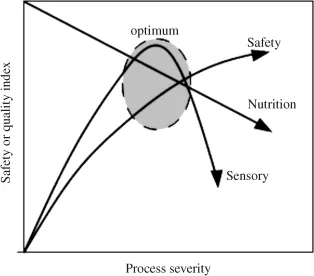

The quality of foods refers first to safety, and then to sensory and nutritional properties. But in many cases, the severity of processing is differently related to safety and to sensory or nutritional quality. Severe processing generally results in higher nutritional loss and in poorer quality, whereas it increases food safety (Fig. 1.2). An optimal drying time and the right level of severity of processing must, therefore, be designed in order to obtain the desired food characteristics.

Fig. 1.2 Effect of process severity on quality index (adapted from Rahman, 2005).

The control of the mentioned properties relies, often in a complex way, on all the chemical and physical phenomena occurring during drying and subsequent storage. The chemical composition of foodstuff is variable and complex, including carbohydrates, proteins, lipids, minerals, vitamins, aromas, and so on. This complexity induces properties that change throughout drying and storage, and that must be controlled. Besides water content and water activity, many factors with positive and negative effects must be considered, such as

- the temperature and humidity conditions during processing,

- the changes in shape, structure, porosity, and mechanical properties,...

Table of contents

- Cover

- Modern Drying Technology

- Title Page

- Copyright

- Series Preface

- Preface of Volume

- List of Contributors

- Recommended Notation

- EFCE Working Party on Drying: Address List

- Chapter 1: Quality Changes in Food Materials as Influenced by Drying Processes

- Chapter 2: Impact of Drying on the Mechanical Properties and Crack Formation in Rice

- Chapter 3: Characterization and Control of Physical Quality Factors During Freeze-Drying of Pharmaceuticals in Vials

- Chapter 4: In-Line Product Quality Control of Pharmaceuticals In Freeze-Drying Processes

- Chapter 5: Understanding and Preventing Structural Changes During Drying of Gels

- Chapter 6: Morphology and Properties of Spray-Dried Particles

- Chapter 7: Particle Formulation in Spray Fluidized Beds

- Index