Doubly Fed Induction Machine

Modeling and Control for Wind Energy Generation

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Doubly Fed Induction Machine

Modeling and Control for Wind Energy Generation

About this book

This book will be focused on the modeling and control of the DFIM based wind turbines. In the first part of the book, the mathematical description of different basic dynamic models of the DFIM will be carried out. It will be accompanied by a detailed steady-state analysis of the machine. After that, a more sophisticated model of the machine that considers grid disturbances, such as voltage dips and unbalances will be also studied. The second part of the book surveys the most relevant control strategies used for the DFIM when it operates at the wind energy generation application. The control techniques studied, range from standard solutions used by wind turbine manufacturers, to the last developments oriented to improve the behavior of high power wind turbines, as well as control and hardware based solutions to address different faulty scenarios of the grid. In addition, the standalone DFIM generation system will be also analyzed.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

- The fixed speed is related to the fact that an asynchronous machine coupled to a fixed frequency electrical network rotates at a quasifixed mechanical speed independent of the wind speed.

- The stall and pitch control will be explained later in the chapter, but is related to the way the wind turbine limits or controls the power extracted from the wind.

Table of contents

- Cover

- Series Page

- Title Page

- Copyright

- Preface

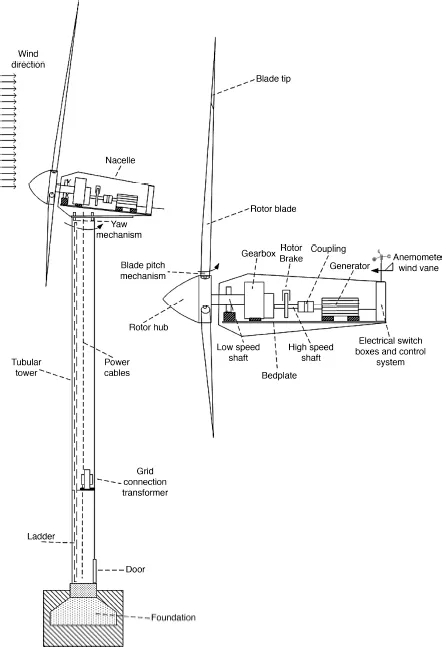

- Chapter 1: Introduction to A Wind Energy Generation System

- Chapter 2: Back-to-Back Power Electronic Converter

- Chapter 3: Steady State of the Doubly Fed Induction Machine

- Chapter 4: Dynamic Modeling of the Doubly Fed Induction Machine

- Chapter 5: Testing the DFIM

- Chapter 6: Analysis of the DFIM Under Voltage Dips

- Chapter 7: Vector Control Strategies for Grid-Connected DFIM Wind Turbines

- Chapter 8: Direct Control of the Doubly Fed Induction Machine

- Chapter 9: Hardware Solutions for LVRT

- Chapter 10: Complementary Control Issues: Estimator Structures and Start-Up of Grid-Connected DFIM

- Chapter 11: Stand-Alone DFIM Based Generation Systems

- Chapter 12: New Trends on Wind Energy Generation

- Appendix

- Index