![]()

Chapter 1

Introduction

1.1 Induction Motor

Conversion from electrical energy to mechanical energy is an important process in modern industrial civilization. About half of the electricity generated in a developed country is eventually converted to mechanical energy, usually by means of electrical machines (Leonhard, 1996; Sen, 1997).

Typical applications of electrical machine drives are:

1. Appliances (washing machines, blowers, compressors, pumps);

2. Heating/ventilation/air conditioning (HVAC);

3. Industrial servo drives (motion control, robotics);

4. Automotive control (electric vehicles).

Since its invention in 1888, the induction motor has become the most widely used motor in industry. Compared with d.c. motors, the cage induction motor has distinct advantages (Novotny and Lipo, 1996) as listed below:

1. No commutator and brushes,

2. Ruggedness,

3. Lower rotor inertia,

4. Maintenance free, simpler protection,

5. Smaller size and weight,

6. Lower price.

Consequently, most industrial drive applications employ induction motors. Unfortunately, the speed of an induction motor cannot be continuously varied without additional expensive equipment. High-performance control of an induction motor is more difficult than d.c. motors, because the induction motor is inherently a dynamic, recurrent, and nonlinear system.

1.2 Induction Motor Control

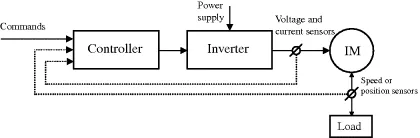

Induction motor control problems have attracted the attention of researchers for many years. Most of the earlier researches are based on classical control theory and electric machine theory, using precise mathematical models of the induction motor. As shown in Figure 1.1, an induction motor control system consists of the controller, sensors, inverter, and the induction motor. It can be seen that a study of induction motor control involves three main electrical engineering areas: control, power electronics, and electrical machines (Bose, 1981).

The induction motor can be described by a fifth order nonlinear differential equation with two inputs and only three state variables are available for measurement (Marino and Tomei, 1995). The control task is further complicated by the fact that the induction motor is subject to unpredictable disturbances (such as noise and load changes) and there are uncertainties in machine parameters. Induction motor control has constituted a theoretically interesting and practically important class of nonlinear systems, and is evolving into a benchmark example for nonlinear control (Ortega and Asher, 1998).

Intelligent control, which includes expert-system control, fuzzy-logic control, neural-network control, and genetic algorithm, is not only based on artificial intelligence (AI) theory, but also based on conventional control theory. Consequently, new control methods can be developed by the application of artificial intelligence (Bose, 1993).

1.3 Review of Previous Work

Scientists and experts have devoted a lot of efforts to induction motor control in the past decades. Developing new control principle, algorithm, and hardware for induction motor control has become a challenge that industry must face today. The development of induction motor control may be summarized as follows.

In 1946, Weygandt and Charp investigated the transient performance of induction motor by using an analog computer (Weygandt and Charp, 1946).

In 1956, Bell Laboratories invented the thyristor (or silicon-controlled rectifier) (Bose, 1989).

In 1959, Kovacs and Racz applied rotating reference frames and space vectors to the study of induction motor transients (Kovacs and Racz, 1959).

Since 1960, various scalar control strategies of constant voltage/frequency (V/Hz) control of induction motor had been proposed (Bose, 1981).

In 1961, McMurray and Shattuck proposed the inverter circuit with pulse width modulation (PWM) (McMurray and Slattuck, 1961).

In 1968 and in 1970, field orientation principle was first formulated by Hasse and Blaschke (Hasse, 1969; Blashke, 1972).

In 1985, direct self control was proposed by M. Depenbrock, I. Takahashi, and T. Noguchi (Depenbrock, 1985; Takahashi and Noguchi, 1986).

In the 1990s, intelligent control of induction motor received wide attention (Bose, 1992).

Recently, revolutionary advances in computer technology, power electronics, modern control, and artificial intelligence have led to a new generation of induction motor control that may provide significant economic benefits.

The voltage or current supplied to an induction motor can be expressed as a sinusoidal function of magnitude and frequency or magnitude and phase. Accordingly, induction motor control methods are classified into two categories: scalar control in which the voltage magnitude and frequency are adjusted, and vector control in which the voltage magnitude and phase are adjusted.

1.3.1 Scalar Control

The scalar controllers are usually used in low-cost and low-performance drives. They control the magnitude/frequency of voltage or current. Typical studies of scalar control include open-loop voltage/frequency (V/Hz) control, closed-loop V/Hz control, and stator current and slip-frequency control (Bose, 1981).

When the load torque is constant and there are no stringent requirements on speed regulation, it suffices to use a variable-frequency induction motor drive with open-loop V/Hz control. Applications which require only a gradual change in speed are being replaced by open-loop controllers, often referred to as general purpose AC drives (Rajashekara, Kawamura, and Matsuse, 1996).

When the drive requirements include faster dynamic response and more accurate speed or torque control, it is necessary to operate the motor in the closed-loop mode. Closed-loop scalar control includes closed-loop V/Hz control and stator current and slip frequency control.

1.3.2 Vector Control (Rajashekara, Kawamura, and Matsuse, 1996)

The vector controllers are expensive and high-performance drives, which aim to control the magnitude and phase of voltage or current vectors. Vector control methods include field-oriented control (FOC) and direct self control (DSC). Both methods attempt to reduce the complex nonlinear control structure into a linear one, a process that involves the evaluation of definite integrals. FOC uses the definite integral to obtain the rotor flux angle, whereas DSC uses the definite integral to obtain the stator flux space vector. Although the implementation of both methods has largely been successful, they suffer from the following drawbacks:

1. Sensitivity to parameter variations;

2. Error accumulation when evaluating the definite integrals; if the control time is long, degradation in the steady-state and transient responses will result due to drift in parameter values and excessive error accumulation;

3. In both methods, the control must be continuous and the calculation must begin from an initial state.

1.3.3 Speed Sensorless Control

Speed sensorless control of induction motors is a new and promising research trend. To eliminate the speed and position sensors, many speed and position estimation algorithms have been proposed recently. These algorithms are generally based on complex calculations which involve the machine parameters and the measurement of terminal voltages and currents of the induction motor. Speed sensorless control can be regarded as open-loop control because the measurement is included in the controller (Rajashekara, Kawamura, and Matsuse, 1996).

1.3.4 Intelligent Control of Induction Motor

Despite the great efforts devoted to induction motor control, many of the theoretical results cannot be directly applied to practical systems. The difficulties that arise in induction motor control are complex computations, model nonlinearity, and uncertainties in machine parameters. Recently, intelligent techniques are introduced in order to overcome these difficulties. Intelligent control methodology uses human motivated techniques and procedures (for example, forms of knowledge representation or decision making) for system control (Bose, 1997; Narendra and Mukhopadhyay, 1996).

1.3.5 Application Status and Research Trends of Induction Motor Control

Among the above control techniques, market evidence shows that up to the present only two have found general acceptance. They are the open-loop constant V/Hz control for low-performance applications and the indirect vector control for high-performance applications (Bose, 1993). Vector control principle, intelligent-based algorithm, and DSP-based hardware represent recent research trends of induction motor control.

1.4 Present Study

The present research status of induction motor control suggests the areas that require further investigation and development. The objective of this book is to investigate intelligent control principles and algorithms in order to make the performance of the controller independent of, or less sensitive to, motor parameter changes. Based on theories of the induction motor and control principles, expert-system control, fuzzy-logic control, neural-network control, and genetic algorithm for induction motor drive will be investigated and developed. The scope of the present book is summarized as follows:

1. Computer modeling of induction motor

The induction motor model typically consists of an electrical model and a mechanical model, which is a fifth-order nonlinear system. Using MATLAB®/Simulink software, three induction motor models (current-input model, ...