- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Siting of permanent and temporary buildings in process areas requires careful consideration of potential effects of explosions and fires arising from accidental release of flammable materials. This book, which updates the 1996 edition, provides a single-source reference that explains the American Petroleum Institute (API) permanent (752) and temporary (753) building recommended practices and details how to implement them. New coverage on toxicity and updated standards are also highlighted. Practical and easy-to-use, this reliable guide is a must-have for implementing safe building practices.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Guidelines for Evaluating Process Plant Buildings for External Explosions, Fires, and Toxic Releases by in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Chemical & Biochemical Engineering. We have over one million books available in our catalogue for you to explore.

Information

Edition

2CHAPTER 1

INTRODUCTION

Catastrophic accidents in the chemical process industries, while uncommon, may affect buildings in or near processing facilities. The likelihood of serious events involving hazardous materials can and has been effectively reduced through the application of process safety management. Specifically, the CCPS Guidelines for Technical Management of Chemical Process Safety (CCPS, 1989a) states:

As the chemical process industries have developed more sophisticated ways to improve process safety, we have seen the introduction of safety management systems to augment process safety engineering activities.

Management systems for chemical process safety are comprehensive sets of policies, procedures, and practices designed to ensure that barriers to major incidents are in place, in use, and effective. The management systems serve to integrate process safety concepts into ongoing activities of everyone involved in operations — from the chemical process operator to the chief executive officer.

These process safety management systems help ensure that facilities are designed, constructed, operated, and maintained with appropriate controls in place to prevent serious accidents. Despite these precautions, buildings close to process plants have presented serious risks to the people who work in them. This observation is prompted by the fact that some buildings that were not designed and constructed to be blast resistant have suffered heavy damage, and in some instances have collapsed when subjected to blast loads from accidental explosions. Serious injury or fatality to the occupants resulted from the building damage. Experience indicates that personnel located outdoors and away from such buildings, if subjected to the same blast, may have a lower likelihood of serious injury or fatality. Building occupants have also been exposed to toxic vapors that enter through forced or natural convection ventilation, and thermal hazards that result from fires near buildings.

Industry associations and insurers have proposed building design and siting guidelines as a means of improving personnel safety. The resulting standards, however, are not universally applicable to all industry sectors and do not ensure consistent levels of safety. Consequently, the chemical processing industries recognizes the need for guidance on a uniform approach to the design and siting of buildings intended for occupancy. The chemical process industries also recognizes that this guidance needs to be practical and consistently applicable across the spectrum of interested industries, and take into account the specific operations and conditions existing at any particular site.

The purpose of this book, Guidelines for Evaluating Process Plant Buildings for External Explosions, Fires and Toxic Releases, Second Edition is to provide guidance to building siting evaluations. The first edition of this book was written in conjunction with the first edition of American Petroleum Institute (API) Recommended Practice (RP) 752, “Management of Hazards Associated with Location of Process Plant Permanent Buildings,” issued in 1995. API developed a recommended practice specific to siting of portable buildings in 2007. The new recommended practice was designated API RP-753 and named “Management of Hazards Associated with Location of Process Plant Portable Buildings” (API, 2007). API completed a major revision of API RP-752 in December 2009 (API, 2009). Development of API RP-753 and revision of API RP-752 prompted updating of this book. This book has an expanded role in providing the guidance for all phases of the building siting evaluation process.

API RP-752 was first published in 1995 and provided a three-stage framework for conducting a building siting evaluation. API RP-752 also included examples of numerical occupancy level criteria that could be used to screen buildings from siting evaluation, and some simplified consequence and risk analysis data. The 2009 edition transformed API RP-752 into a management process for siting evaluations, and removed most technical content. Portable buildings were removed from the scope of API RP-752 when API RP-753 was issued, and the scope of API RP-752 was clarified to encompass new and existing rigid structures intended to be permanently placed in fixed locations. Tents, fabric enclosures, and other soft-sided structures are therefore outside the scope of API RP-752.

API RP 752 (API, 2009) and RP 753 (API, 2007) have a set of guiding principles for building siting evaluations. API RP 752 guiding principles are shown below. API RP 753 has a similar set, but modified to be more suitable to portable buildings. The API RP-752 guiding principles are:

- Locate personnel away from process areas consistent with safe and effective operations;

- Minimize the use of buildings intended for occupancy in close proximity to process areas;

- Manage the occupancy of buildings in close proximity to process areas;

- Design, construct, install, modify, and maintain buildings intended for occupancy to protect occupants against explosion, fire and toxic material releases;

- Manage the use of buildings intended for occupancy as an integral part of the design, construction, maintenance, and operation of a facility.

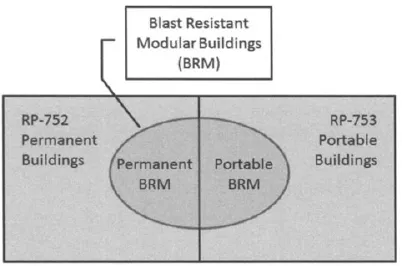

Figure 1.1 depicts the relationship between API RP-752 and API RP-753. Blast resistant modular buildings (BRM) can potentially fall within the scope of either API RP-752 or API RP-753 depending on the intended use of the BRM. BRMs that are intended for permanent installation in a fixed location fall within the scope of API RP-752, whereas all temporary applications fall within the scope of API RP-753, This book addresses both permanent and temporary buildings and provides analysis methods that support both of the API recommended practices.

Figure 1.1. Relationship between API RP-752 and API RP-753

API RP-753 includes restrictions on personnel who can be located in portable buildings in certain circumstances. Only essential personnel are allowed in selected portable buildings close to and within process units (API RP-753 Zone 1) when the building has been subjected to a detailed analysis for the hazards at the building location. No such personnel restrictions are included in API RP-752 for permanent buildings; instead, all buildings intended for occupancy undergo a detailed analysis for explosion hazards.

It is not the role of this book to create any additional building siting requirements beyond those defined in API RP-752 and API RP-753. The reader should review both recommended practices before reading this book. Guidance on all aspects of the building siting evaluation process can be found in this book. This book serves as a roadmap to references including CCPS documents.

A wide variety of technical and process safety management issues are referenced throughout this book. Detailed coverage of these issues is outside the scope of this book, however, and readers are referred to other CCPS books for more information. These include, in particular:

- Guidelines for Technical Management of Chemical Process Safety (CCPS, 1989a)

- Guidelines for Hazard Evaluation Procedures, Third Edition, with worked examples (CCPS, 2008b)

- Guidelines for Chemical Process Quantitative Risk Analysis (CCPS, 2000)

- Guidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE and Flash Fire Hazards (CCPS, 2010)

- Guidelines for Use of Vapor Cloud Dispersion Models (CCPS, 1987)

- Guidelines for Vapor Release Mitigation (CCPS, 1988)

- Guidelines for Facility Siting and Layout (CCPS 2003a)

- Guidelines for Developing Quantitative Safety Risk Criteria (CCPS 2009b)

- Guidelines for Fire Protection in Chemical, Petrochemical, and Hydrocarbon Processing Facilities (CCPS, 2003b).

- Guidelines for Risk Based Process Safety (CCPS, 2007)

Additionally, the following references also provide guidance:

- U.S. Army, “Structures to Resist the Effects of Accidental Explosions” (U.S. Army, 1991)

- American Society of Civil Engineers, Design of Blast Resistant Buildings in Petrochemical Facilities (ASCE, 2010)

- American Society of Civil Engineers, Structural Design for Physical Security (ASCE, 1999)

- “Single Degree of Freedom Structural Response Limits for Antiterrorism Design,” (U.S. Army COE, 2006)

1.1 OBJECTIVE

The objective of these guidelines is to provide a practical approach to implementing a building siting evaluation for process plant buildings in accordance with API RP-752 and RP-753. Note that API RP-752 and RP753 provide the process by which building siting evaluations are conducted for permanent and portable buildings, respectively. However, these recommended practices do not provide the technical methods needed to conduct a building siting evaluation.

API RP-752 now requires a building siting evaluation of all permanent buildings intended for occupancy that are located on sites covered by the OSHA PSM regulation (29 CFR 1910.119). The analysis methods described in this book are not limited to U.S. OSHA PSM covered facilities and can be used for any buildings an owner/operator wishes to evaluate; in fact, other countries may have regulatory requirements that differ from the U.S. This book is applicable to onshore facilities and does not address circumstances that exist in offshore installations. API RP-753 has similar requirements for detailed analysis of portable buildings unless a portable building is sited beyond a distance determined by a conservative simplified analysis method for vapor cloud explosions (VCE). Even the API RP-753 simplified method requires site-specific data in terms of process unit congested volume to calculate the siting distance.

The purpose of this book is to provide the methods to address the explosion, fire and toxic impacts to process plant buildings and occupants occurring as a result of hazards associated with operations external to the building.

Discussion of the following hazards is beyond the scope of this book:

- natural hazards;

- terrorist attack;

- fire and toxic impacts to off-site personnel and on-site personnel in open areas or within non-building structures; and

- secondary or “knock-on” effects that develop relatively slowly, allowing sufficient time for personnel to evacuate buildings.

1.2 BUILDING SITING EVALUATION PROCESS

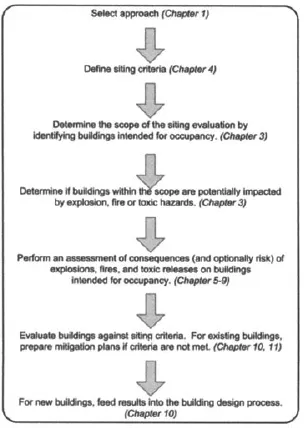

This book is organized around the overall building siting evaluation process in API RP-752 as depicted in Figure 1.2. Readers are encouraged to read this entire guideline before starting or revising a building siting evaluation. Chapter numbers that provide guidance for each step are shown in parentheses.

Figure 1.2. Overall Process for a Building Siting Evaluation

1.3 SELECTION OF APPROACH

The building siting process begins with selection of the approach that will be followed. The approach may be consequence-based or risk-based as explained in Chapter 2, Section 2.1.3. A consequence-based methodology does not include consideration of the frequency with which an explosion, fire or toxic scenario may occur; rather, the analysis is limited to computation of the damage or injury that may result from the postulated sce...

Table of contents

- Cover

- Half Title page

- Title page

- Copyright page

- List of Figures

- List of Tables

- Acknowledgments

- Glossary

- Chapter 1: Introduction

- Chapter 2: Management Overview

- Chapter 3: Determining the Scope of the Building Siting Evaluation

- Chapter 4: Building Siting Evaluation Criteria

- Chapter 5: Explosion Hazards

- Chapter 6: Fire Hazards Assessment

- Chapter 7: Toxic Hazards Assessment

- Chapter 8: Frequency and Probability Assessment

- Chapter 9: Risk Assessment

- Chapter 10: Mitigation Plans and Ongoing Risk Management

- Chapter 11: Managing the Building Siting Process

- References

- Index