eBook - ePub

Mechanised Shield Tunnelling

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Mechanised Shield Tunnelling

About this book

Mechanised shield tunnelling has developed considerably since the publication of the first edition of this book. Challenging tunnel projects under difficult conditions demand innovative solutions, which has led to constant further development and innovation in process technology, constructions operations and the machines and materials used.

The book collects the latest state of technology in mechanised shield tunnelling. It describes the basics of mechanised tunnelling technology and the various types of machines and gives calculation methods and constructural advice. Further chapters cover excavation tools, muck handling, tunnel support, surveying and steering as well as workplace safety. There is also detailled information about contractual aspects and process controlling.

The book collects the latest state of technology in mechanised shield tunnelling. It describes the basics of mechanised tunnelling technology and the various types of machines and gives calculation methods and constructural advice. Further chapters cover excavation tools, muck handling, tunnel support, surveying and steering as well as workplace safety. There is also detailled information about contractual aspects and process controlling.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Introduction

The mined construction of underground infrastructure has made steady progress over recent years. It is now possible to construct underground works with very little impairment of buildings or traffic flow at ground level. Particularly in inner-city areas, with sensitive infrastructure and high population density, there is an enormous demand for underground structures.

The cavities created in this way have until now mostly been for underground transport routes, although there are also other possible uses such as energy extraction, storage and refuge spaces, utility tunnels and, not least, underground urban development. This has led to extensive schemes and projects, particularly in Japan due to the very restricted space availability (Figure 1-1).

Particularly in the field of shield tunnelling, the prominent role of Japan has been unmistakeable. But the development of this construction method is also at a high and internationally respected level in Germany and other parts of Europe. The shield construction process enables the production of elongated underground structures, even at shallow depths, in soil with poor load-bearing capacity or under the groundwater table, without causing any disturbance or significant settlement on the ground surface. Ground conditions with loose spherical material can be mastered, as can soft plastic or flowing soils. But the use of these machines is also practicable in temporarily stable ground, where the shield only acts as head protection. All in all, shield machines have a wide scope of application.

Figure 1-1 Japanese scheme for the exploitation of underground space in an inner-city area [155]

The shield construction process could but should not generally replace other methods of tunnelling. It can, however, offer a technically feasible and also economic alternative to other methods of tunnelling in unfavourable geological conditions, for long contract sections, high advance rate requirement or where stringent surface settlement limits apply. The essential advantages and disadvantages are summarised below.

Advantages:

– the possibility of mechanisation and high advance rate,

– precision of profile,

– minimisation of the effect on buildings on the surface,

– improved safety for the miners,

– environmentally friendly construction method,

– raising of the groundwater table,

– little noise,

– enables a high-quality and economic lining.

Disadvantages:

– long lead time for the design, production and assembly of the shield machine,

– long familiarisation time,

– elaborate and expensive site facilities (a separating plant may be required); tenders may only be competitive for longer tunnels,

– performance risk in changeable ground,

– the cross-section normally has to be round with little possibility of variation,

– high cost of altering the excavated geometry, e.g. for wider sections,

– the lining normally has to be specially designed to resist the thrust forces.

Application is therefore practicable where the advantages can be sensibly exploited and the disadvantages are taken into account as far as possible in the design and construction planning. Experience shows that a shield in the smaller diameter range can generally compete with other tunnelling methods for tunnel drives up to 2,000 m. For longer tunnels, economic applications of shield machines are possible and even cheaper than using open machines or conventional methods.

The successful use of a shield always requires meticulous design and planning of the machine, the lining and the logistics. Experience and know-how are essential for a practicable and economic scheme. According to [235], too many clients have chosen the wrong machine or construction concept for the ground conditions and have later been faced with unacceptable settlement on the surface, unexpectedly slow advance rates, spalling or failure of the lining, water ingress or other defects. For the client, only a tunnel constructed on schedule, of good quality and at reasonable cost, and with as little impact on the environment as possible is of interest. The designers of shield equipment need to take these natural concerns into consideration. Mechanical engineering issues have to be effectively linked to those of the tunnel itself. Constant exchange of experience between mechanical and civil engineers is essential, with the appropriate evaluation of experience from completed projects.

1.1 Basic principles and terms

The basic principle of a shield is that a generally cylindrical steel construction is driven along the tunnel axis while the ground is excavated. The steel construction supports the excavated cavity until temporary support or the final lining has been installed. The shield therefore has to resist the pressure of the surrounding ground and hold back any groundwater.

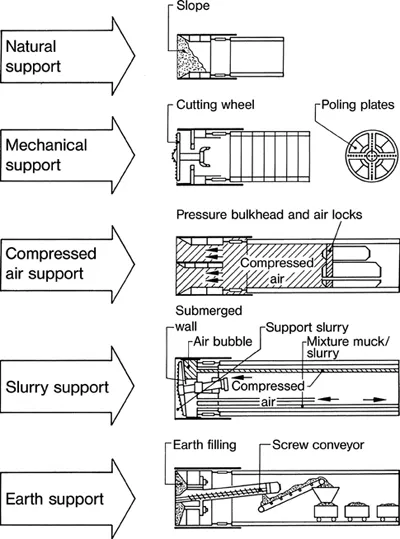

While the cavity along the sides of the tunnel is supported by the shield skin itself, additional support measures will be required to support the face, depending on the ground and groundwater conditions encountered. Figure 1-2 shows five different methods of stabilising the face, which are described in detail in Chapter 2. These are:

– natural support,

– mechanical support,

– compressed air support,

– slurry support,

– earth pressure balance support.

These methods of supporting the face represent the great advantage of the shield tunnelling process. In contrast to other methods of tunnelling, it is possible to provide immediate support of the ground as soon as it is disturbed.

In addition to the type of face support, the method of excavation is an important characteristic of shields. The most simple process is manual digging in hand shields, and this is still used today in exceptional cases, for example for short sections and under certain geological conditions. Mechanical excavation is, however, more usual. This can be differentiated into mechanical partial- and full-face excavation. In partial-face excavation, the face is worked in sections using machinery such as hydraulic excavators or roadheaders, which are operated and controlled either by operators or automatically. The full face can be excavated, according to the ground conditions encountered, by open-mode wheels, rim wheels (in some cases with shutters) or closed cutter heads. Further methods are hydraulic excavation using pressurised jets of fluid and extrusion excavation, where the action of the thrust cylinders on highly plastic soil forces it through closable openings in the front wall of the shield. Excavation processes are described in more detail in Chapter 4.

The removal of the excavated material requires special transport systems to move the muck from the face, through the shield and to the surface. The most suitable system depends directly on the nature of the ground encountered and the associated type of face support and excavation, since these factors have a great influence on the consistency and transport properties of the muck. Figure 1-3 gives an initial overview of the possible transport systems through the shield, which will be explained in more detail in Chapter 5. There are numerous transport methods available today, which can be categorised into the three basic groups

– dry transport,

– fluid/slurry transport,

– high-density solid pumping.

Transport along the tunnel can use pumped pipes, conveyor belts, dumpers or rail-based systems (muck trains). The transfer area to the tunnel transport system is integrated into the backup.

Figure 1-2 Methods of supporting the ground and holding water at the face [266]

The shield is pushed forward in the direction of the tunnel axis with the progress of excavation in order to support the resulting cavity. The required thrust forces are produced by hydraulic cylinders, normally pushing against the already installed lining. This means that the tunnel lining and boring machinery have to be finely matched. The correct function of the shield and the quality of the final tunnel lining both depend on this compatibility, which is dealt with in more detail in Chapter 6.

The cavity produced by excavation is mostly supported with precast elements called segments. There are numerous different forms, materials, possible layouts, sealing systems and installation methods, which require detailed description (Chapter 6). Other lining systems are also possible and are already in use today (Figure 1-4). The pumping of concrete under pressure into formwork (called the extrusion process) is an interesting possibility, but has not been further developed. Even shotcrete can be used in connection with shield tunnelling.

As the support is normally installed inside the protection of the shield skin, a gap remains as the shield progresses further. The gap has to be filled in order to minimise loosening and settlement. This has...

Table of contents

- Cover

- Contents

- Title

- Copyright

- The authors

- Foreword to the 2nd Edition

- 1 Introduction

- 2 Support of the cavity and settlement

- 3 Design and calculation methods

- 4 Excavation tools and excavation process

- 5 Muck removal

- 6 The tunnel lining

- 7 Shield tail sealing, grouting works

- 8 Open shields

- 9 Compressed air shields

- 10 Slurry shields

- 11 Earth pressure balance shields

- 12 Convertible shields or multi mode machines

- 13 Special shields and special processes

- 14 Guided microtunnelling processes

- 15 Surveying and steering

- 16 Workplace safety

- 17 Partnering contract models and construction

- 18 Process controlling and data management

- 19 DAUB recommendations for the selection of tunnelling machines

- Bibliography

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Mechanised Shield Tunnelling by Bernhard Maidl,Martin Herrenknecht,Ulrich Maidl,Gerhard Wehrmeyer, David S. Sturge in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Civil Engineering. We have over one million books available in our catalogue for you to explore.