![]()

1 Basic Principles

1.1 Definition

According to DIN EN 450-1 “Fly ash for concrete” [N 6], fly ash is a fine powder of mainly spherical, glassy particles derived from burning of pulverized coal. It has pozzolanic properties and consists essentially of SiO2 and Al2O3, the content of reactive SiO2 being at least 25 mass %. Fly ash is obtained by electrostatic or mechanical precipitation of dust-like particles from the flue gases of furnaces fired with pulverised coal, with or without co-combustion materials.

With the exception of one lignite fly ash approved by the building authorities, all types of fly ash used as a concrete addition in Germany have a low reactive lime content and a high reactive SiO2 content. They are known as siliceous or silicon-rich fly ash and may also come from lignite-fired power plants.

To date, calcareous fly ash (reactive CaO > 10 mass %) has not been provided for use as a concrete addition in Germany (aside from the aforementioned exception). However, according to DIN EN 197-1 [N 3], calcareous fly ash may be used as a main constituent in the production of fly ash cement CEM II/A-W or CEM II/B-W. As cements of this type are not produced as yet in Germany, and the use of calcareous fly ash as a concrete addition is also not generally permitted at the present time, this type of fly ash will not be discussed here.

In this book, fly ash should be understood to mean siliceous fly ash in accordance with DIN EN 450-1. This type of fly ash is generally obtained by firing hard coal and is therefore frequently referred to in the literature as hard coal fly ash.

However, fly ash conforming to DIN EN 450-1 can also be produced by processing in suitable production plants. The processed fly ash may consist of fly ash from different sources complying with the above definition. If one or more of the initial fly ashes is produced in power plants with co-combustion of secondary fuels, the processed fly ash is considered to be fly ash obtained via co-combustion, for which specific verification is required.

1.2 Historical development

As early as the 1930s, efforts were made to find a use in the building materials industry for the increasing amounts of fly ash produced when firing coal in large power plants in Europe and America. One proposal was to use it as a substitute for cement as an addition in autoclaved aerated concrete and concrete blocks. In the U.S.A., fly ash was used to replace 35 % of the Portland cement in about 3 million m3 of concrete during construction of the Hungry Horse Dam in Montana in 1948. In Germany, only fly ash from hard coal power stations was initially used, due to the fact that it was available at the quality required and had the desired degree of uniformity.

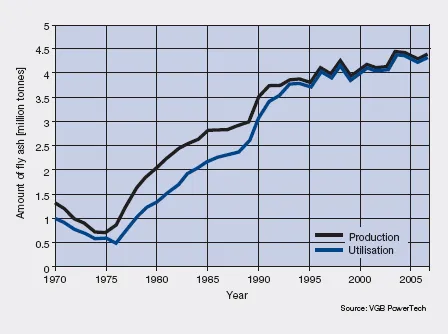

Fig. 1.2-1: Development in the production and utilisation of fly ash from hard coal power plants in Germany

In Germany, fly ash began to be used in significant amounts in the 1960s and, owing to the increasing amounts being produced, became an economic and ecological necessity from the mid-1970s onwards (Fig. 1.2-1). Since the mid-1990s, almost 100 % of the fly ash generated in hard-coal-fired power plants has been used in the production of building materials, of which 75 % has been used to make all types of concrete.

It took more than 10 years, by convincing potential users, developing the necessary logistic infrastructure and opening up the market for the product fly ash, to reach today’s successful outcome. One of the initial problems which had to be dealt with was the fact that the use of fly ash was not regulated in the sector of building construction relevant to the building inspectorate and was not included in constructional regulations. This applied to all applications of fly ash, but in particular to its use in concrete, which already represented a significant market at that time. A crucial breakthrough was made in this regard on 29 June 1970, when the German State of North Rhine-Westphalia, as the highest building authority, granted H. Keller, a company which sold and distributed by-products from German coal-fired power plants, a technical approval for “EFA-Füller RM” fly ash from the Rheinstahl power plant in Marl as a binder for use in combination with cement. This decision was crucial from a cost perspective, as the approval allowed some of the cement required for concrete to be replaced by fly ash, and the recognition given to fly ash as a binder component attracted the interest of concrete manufacturers. Unfortunately, it was not long before this positive development was brought to a halt when the German states assigned some of their responsibilities for building inspection to the Institute of Building Technology. This Institute was founded in 1969 and, to begin with, no longer allowed fly ash to be counted in the total binder content as a binder for use in combination with cement. Fly ash had been granted 31 marks of approval by 1979, but the industry had to wait until 1983 for new regulations allowing fly ash to be counted as part of the binder content. However, these new regulations were far more restrictive than the building inspectorate approval given in 1970. By 1995, a total of 85 marks of approval had been granted on the basis of the “Guidelines for Granting Marks of Approval for Hard Coal Fly Ash”, developed in 1980 by the Institute of Building Technology and the subsequent (1990) “Guidelines for Granting Approval for Inorganic Concrete Additions (Approval Directive)” [R 1].

It was necessary to perform extensive research to establish the current value of the “countability factor” of k = 0.4 in the approvals. Fly ash became a standard building material when DIN EN 450 [N 5] was introduced by the building inspectorate in 1996. Building inspectorate approvals are now granted only for fly ashes not covered by the standard, such as fly ash produced by firing hard lignite and lignite as well as fly ash produced by the co-combustion of sewage sludge or petroleum coke.

As a result of new technological developments in the power industry and knowledge gained from the application of DIN EN 450, fly ash from co-combustion power plant...