- 192 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Picture History of World War II American Aircraft Production

About this book

One of the greatest industrial feats of World War II — indeed of all time — was the massive production of military aircraft by American manufacturers. America's sudden entry into the war required its typically small aircraft "job shops" to convert quickly to assembly-line techniques to meet the urgent demand for fighters and bombers. In many ways, Allied victory depended on the success of this conversion. How Americans heroically met the challenge is the focus of this fascinating pictorial history.

Over 250 rare photographs — most never published before — comprise an eye-filling chronicle of men and women hard at work in a crucial wartime industry: hooking up an engine, hanging a propeller, riveting the "skin" on a fuselage and performing many other tasks. Also included are authentic, on-the-spot photographs of aircraft assembly lines in full swing, of teams of workers turning out Boeing B-17 bombers in Seattle, huge B-24D "Liberators" at the Ford plant in Willow Run, Michigan, and F6F Grumman "Hellcat" fighters in Bethpage, Long Island, New York.

In his informative Introduction and captions, the author outlines the history of this massive effort, explains production processes and describes aircraft construction, assembly and armament. Throughout, he emphasizes important but often overlooked aspects of the story: how this struggle produced the first (and only) true mass production of military aircraft in history; introduced large numbers of women and minorities into the skilled work force; and inspired one of the greatest periods of high morale and camaraderie among workers ever seen.

Aviation enthusiasts, World War II veterans and students of American history and sociology will find this a truly fascinating chapter in the American experience, superbly presented and carefully documented. Joshua Stoff is Air and Space Curator, Cradle of Aviation Museum, Mitchel Field, Long Island, New York.

Over 250 rare photographs — most never published before — comprise an eye-filling chronicle of men and women hard at work in a crucial wartime industry: hooking up an engine, hanging a propeller, riveting the "skin" on a fuselage and performing many other tasks. Also included are authentic, on-the-spot photographs of aircraft assembly lines in full swing, of teams of workers turning out Boeing B-17 bombers in Seattle, huge B-24D "Liberators" at the Ford plant in Willow Run, Michigan, and F6F Grumman "Hellcat" fighters in Bethpage, Long Island, New York.

In his informative Introduction and captions, the author outlines the history of this massive effort, explains production processes and describes aircraft construction, assembly and armament. Throughout, he emphasizes important but often overlooked aspects of the story: how this struggle produced the first (and only) true mass production of military aircraft in history; introduced large numbers of women and minorities into the skilled work force; and inspired one of the greatest periods of high morale and camaraderie among workers ever seen.

Aviation enthusiasts, World War II veterans and students of American history and sociology will find this a truly fascinating chapter in the American experience, superbly presented and carefully documented. Joshua Stoff is Air and Space Curator, Cradle of Aviation Museum, Mitchel Field, Long Island, New York.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Picture History of World War II American Aircraft Production by Joshua Stoff in PDF and/or ePUB format, as well as other popular books in History & Military & Maritime History. We have over one million books available in our catalogue for you to explore.

Information

Fuselage Construction

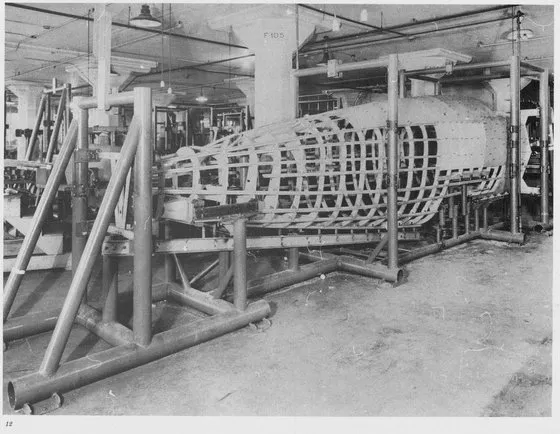

12. For some years from its inception in 1932, the Brewster Aeronautical Corporation remained a relatively small organization. Not until 1939 did the work force exceed 1,000. With the start of production of their first fighter, the F2A “Buffalo,” in 1940, the work force soared to 7,000. This was Brewster’s first, and most famous, production aircraft, first ordered in 1936. It had a Wright R-1820 engine, hydraulically retractable landing gear, and all-metal stressed-skin flush-riveted construction. It was assured its place in history as the U.S. Navy’s first operational monoplane fighter. Brewster President James Work clung to the idea that an urban aircraft factory was possible. This belief resulted in an inadequate, inefficient plant in Long Island City, New York. Brewster set up shop in the old seven-story Ford building, thus resulting in the only vertical aircraft factory in the world. By necessity, aircraft under construction had to be maneuvered around posts and up and down the only elevator in the building. Brewster’s cramped conditions at its Long Island City plant are plainly evident in this 1939 photo, as this Buffalo fuselage receives its skin. (Photo: Jim Maas.)

13. The Curtiss P-40 “Warhawk,” developed from the P-36, was America’s foremost fighter in service when World War II began. P-40’s engaged Japanese aircraft during the attack on Pearl Harbor and the invasion of the Philippines in December 1941. They were also flown in China by the famed Flying Tigers in 1942. Historically the P-40 is one of the more controversial American fighters of World War II. Clearly it was inferior to most German and Japanese fighters, yet the fact remains that in the dark days following Pearl Harbor America had only one fighter plane in quantity production—the Curtiss P-40. The P-40 fuselage was of full monocoque construction built in upper and lower halves joined along the horizontal centerline. The forward half of the fuselage consisted of the pilot’s quarters and his controls and instruments. The rear half housed the baggage compartment, accessory equipment and tail gear. These P-40E fuselages in Curtiss’ Buffalo, New York, plant, in 1941, await their engine mounts and cockpit equipment before moving onto the final assembly line. (Photo: National Air and Space Museum, Washington, D.C.)

14. The Curtiss C-46 “Commando,” widely used in the Pacific Theater during World War II, was the largest and heaviest twin-engine plane in operational use by the Army Air Corps. The plane originated in a 1937 design for a 36-passenger luxury airliner, the prototype of which was built in St. Louis in 1940. Army interest was aroused by this new airliner because of its especially large fuselage. A contract was placed for 46 units of a military version, designated C-46. In May 1942, the first C-46 was rolled out of the Curtiss factory in Buffalo. The C-46 was designed to be pressurized for substratosphere flying, which resulted in a sturdy and unusual fuselage design. The C-46 fuselage shown in this 1942 photo is just beginning to get its skin attached. The vertical bulkheads are connected by horizontal stringers. (Photo: National Art and Space Museum.)

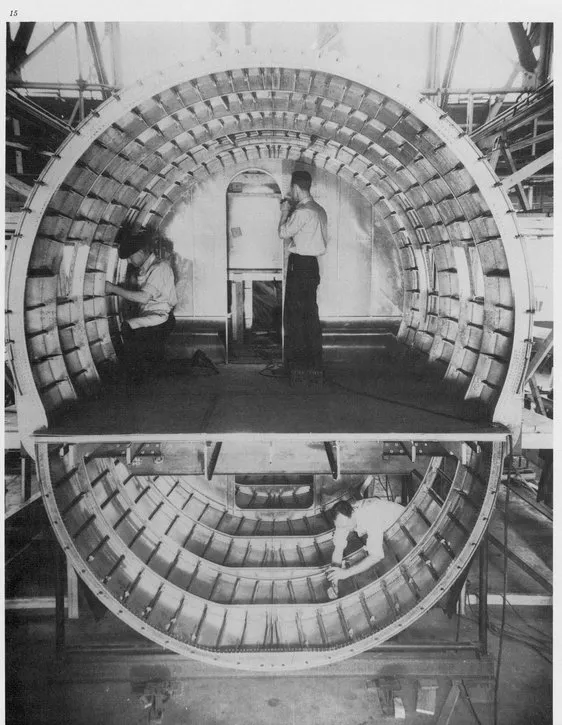

15. As it was to ve pressurized, the C-46 fuselage was rather interesting. In cross section it was formed of two intersecting circles with the common chord of intersection being the cabin floor line. A circular section was decided upon because it was ideal for pressurization. However, one circle for the size of airplane incolved would have presented excessive frontal area that would have greatly reduced aerodynamic efficiency. But by using two circles, frontal area was reduced without losing the ideal pressure section, and the common chord line served the dual purpose of tying the circles together and providing the floor structure. Flush riveting was used in the drag-sebsitive areas of the fuselage. These workers complete the fuselage center section prior to attachment of the nose.(Photo: National Air and Space Museum.)

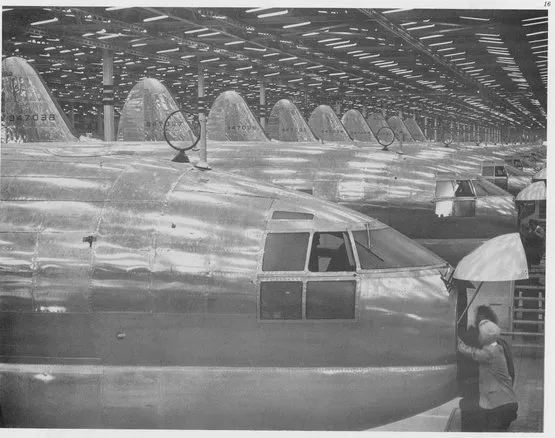

16. With the successful introduction of the Curtiss C-46 into service with the Air Transport Command and Troop Carrier Command in 1942, coupled with the pressing need to provide the U.S. Army with airlift capability, orders for the C-46 mounted rapidly. The C-46A had a large cargo door in the rear fuselage and folding seats along the cabin walls for 40 troops. From this photo it is obvious how the windshield was designed to follow the contour of the fuselage to increase performance. The fuselage nose was also readily removable to facilitate inspection and service of plumbing and wiring in back of the instrument panel. (Photo: National Air and Space Museum.)

17. The fuselage of the C-46 provided approximately 2,300 cubic feet of cargo space. The floor, adjacent to the cargo door in this photo, was practically level (the main portion of floor was but 9.5 degrees from horizontal) to expedite loading and unloading when the aircraft was on the ground. Evident here are rows of metal tubes running the full length of the compartment, which were intended to protect the fuselage walls from damage by cargo. (Photo: National Air and Space Museum.)

18. The Naval aircraft that took the brunt of the fighting in the early part of World War II, while superior aircraft were still taking shape, was the Grumman F4F “Wildcat.” Once the war began in Europe, isolationism was perceived to be a dangerous course for the U.S. Thus, while in 1939 the Navy had placed orders for just 78 of the original F4F Wildcats, total F4F orders for 1940 amounted to 759. Here Wildcat fuselages are taking shape at Grumman’s Bethpage, New York, Plant 2, in 1941. Plant 2 was the first plant erected at Government expense for a defense contractor under the Emergency Plant Facilities Act. These F4F’s will be receiving their engines in the next station. Wing- and tail-surface attachment will follow. (Photo: Grumman Aerospace Corp.)

19. The Grumman F4F retained the distinctive blunt appearance that characterized earlier Grumman fighters. The single fixed wing was mounted squarely on the fuselage centerline, and the retractable landing gear was operated by a handcrank. The Wildcat was powered by a 1,050-hp Pratt & Whitney R-1830 engine. More than any other U.S. aircraft manufacturer, Grumman was to concentrate its wartime effort at one site, Bethpage, building aircraft chiefly for one customer—the U.S. Navy. This F4F has had its engine mated, and internal connections are now being made. The windscreen has already been masked for painting. (Photo: Grumman Corporation, Bethpage, N. Y.)

20. The Grumman F6F “Hellcat” started out as a modification of the F4F Wildcat—larger, faster and greatly improved—in 1942. As the design developed, however, it turned out to be a very different airplane, now powered by the 2,000-hp Pratt & Whitney R-2800 engine. The main problem with the Hellcat, though, was not the needed modifications, but rather how to get it into production fast enough. The first Grumman Hellcats were built on a preproduction line at Grumman’s Bethpage works, while a new plant dedicated solely to F6F production was being constructed in 1942. To avoid delay while the Navy acquired the necessary priorities for the issue of steel for the new plant, Grumman’s President, “Jake” Swirbul, bought steel beams as scrap from New York’s old Second Avenue elevated railway and assembled them into Plant 3 (also in Bethpage). The first production jigs were erected in October, and F6F’s started moving down the assembly line before the plant itself had been finished. Here, Hellcat fuselages take shape in Plant 3. Wing stubs and tail surfaces will be attached next. (Photo: Grumman Corporation.)

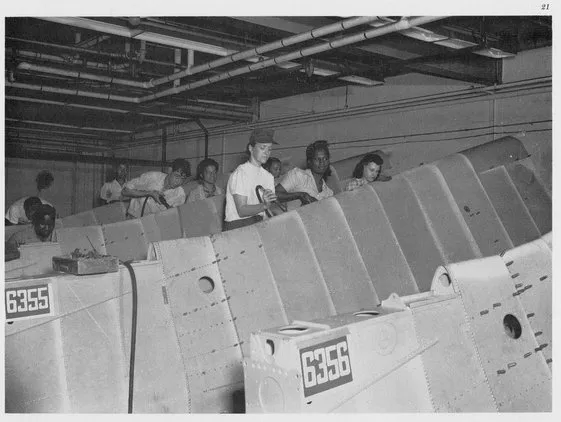

21. The first Grumman F6F was built in August 1942; in five months the F6F productivity curve had sprung upward, and they began to roll off the assembly line. This was unheard-of speed in an industry that used to need years to move from blueprints to planes. One full Hellcat squadron was ready and delivered by December. The Hellcat was the only U.S. fighter ever that from the first example required no developmental work before it could successfully engage in combat. Here, a work force mostly of women rivets the skin on Hellcat fuselage aft sections. As Grumman needed thousands of new workers to build their Hellcats, they were among the first companies to hire large numbers of black workers, drawing on nearby Long Island and New York communities. (Photo: Grumman Corporation.)

22. A worker at Grumman rivets the skin on a Hellcat fuselage aft section. Another worker on the inside will flatten the rivet with a bucking ...

Table of contents

- Dover Maritime Books

- Title Page

- Copyright Page

- PREFACE

- Table of Contents

- INTRODUCTION

- Production Processes

- Prewar Production

- Fuselage Construction

- Wing Construction

- Subcontractors and Subassemblies

- Tail Assemblies

- Mating Wings

- Engine Installation

- Armament

- Painting

- Final Assembly

- Rollouts

- Morale Builders

- Milestone Aircraft

- Shipping

- End of the Line

- Afterword - Where Are They Now?

- Glossary

- Appendix A

- Appendix B

- Appendix C

- Appendix D

- Appendix E

- Index - The numbers are caption numbers unless otherwise indicated.