![]()

THE THIRD BOOK

The Art of the Metalworker

![]()

Prologue

The greatest of the Prophets, David (whom the Lord God in His wisdom predestined before the ages of time, whom He chose “after His own heart”71 for the simplicity and humility of his mind, whom He appointed prince over His beloved people, whom He strengthened with princely spirit so that he might nobly and wisely establish a regime of such renown), concentrating the whole power of his mind toward love of his Creator, uttered, among others, these words: “Lord, I have loved the beauty72 of Thy house.”

Whether a man of such authority and capacious understanding meant by this house the habitation of the celestial court in which God presides with inestimable brightness over the singing choirs of angels (for which David himself yearned with all his inmost being, saying, “One thing have I desired of the Lord, that I will seek after; that I may dwell in the house of the Lord all the days of my life”)73 or whether he meant the refuge of a devout breast and a most pure heart (in which God truly dwells, a guest ardently desired by David, who prays, “Renew a right spirit within me, O Lord”),74 nevertheless it is certain that he avidly desired the embellishment of the material house of God, where is the place of prayer. For he entrusted to his son Solomon almost all the materials—gold, silver, brass, and iron—for the Lord’s house, to be the founder of which he himself yearned with most ardent desire although he was not worthy because of his frequent shedding of human, albeit enemy, blood.75 For he had read in Exodus76 that the Lord had given instructions to Moses to build a tabernacle, had chosen by name the masters for the various kinds of work, and had filled them with the spirits of wisdom, of understanding, and of knowledge in order that they might devise and execute work in gold and in silver and in brass, in precious stones, in wood, and in universal craftsmanship. He knew from devout reflection that God delights in embellishment of this kind, which he was arranging to be executed under the direction and authority of the Holy Spirit, without whose inspiration he believed no one could attempt anything of this kind.

Therefore, most beloved son, you should not doubt but should believe in full faith that the Spirit of God has filled your heart when you have embellished His house with such great beauty and variety of workmanship. And lest perhaps you are diffident, I shall unfold clearly and systematically that whatever in the arts you can learn, understand, or devise, is bestowed on you by the grace of the seven-fold Spirit.77

Through the spirit of wisdom you know that created things proceed from God and that without Him nothing is.

Through the spirit of understanding, you have received the capacity for practical knowledge of the order, the variety, and the measure that you apply to your various kinds of work.

Through the spirit of counsel you do not hide away the talent given you by God, but, working and teaching openly and with humility, you faithfully reveal it to those who desire to learn.

through the spirit of fortitude you shake off all the apathy of sloth, and whatever you commence with quick enthusiasm you carry through to completion with full vigor.

through the spirit of knowledge that is given to you, you are the master by virtue of your practical knowledge and you use in public the perfect abundance of your abounding heart with the confidence of a full mind.

Through the spirit of piety you set a limit with pious consideration on what the work is to be, and for whom, as well as on the time, the amount, and the quality of work, and, lest the vice of greed or cupidity should steal in, on the amount of the recompense.

Through the spirit of the fear of the Lord you bear in mind that of yourself you are nothing able and you ponder on the fact that you possess and desire nothing that is not given to you by God, but in faith, trust, and thankfulness you ascribe to divine compassion whatever you know or are or can be.78

Inspired by these covenants with the virtues, dearest son, you have confidently approached the house of God and decorated it well and gracefully. By setting off the ceiling panels and walls with a variety of kinds of work and a variety of pigments, you have shown the beholders something of the likeness of the paradise of God, burgeoning with all kinds of flowers, verdant with grass and foliage, cherishing the souls of the saints with halos according to their merit. Thus you have caused them to praise God the Creator in this creation and to proclaim Him marvelous in his works. A human eye cannot decide on which work it should first fix its attention; if it looks at the ceiling panels, they bloom like tapestries; if it surveys the walls, the likeness of paradise is there; if it gazes at the abundance of light from the windows, it marvels at the inestimable beauty of the glass and the variety of this most precious workmanship. But if a faithful soul should see the representation of the Lord’s crucifixion expressed in the strokes of an artist, it is itself pierced; if it sees how great are the tortures that the saints have endured in their bodies and how great the rewards of eternal life that they have received, it grasps at the observance of a better life; if it contemplates how great are the joys in heaven and how great are the torments in the flames of hell, it is inspired with hope because of its good deeds and shaken with fear on considering its sins.

Therefore, act now, prudent man (happy before God and men in this life, happier still in the future life), by whose labor and zeal so many burnt offerings are being shown to God. Henceforth be fired with greater ingenuity: with all the striving of your mind hasten to complete whatever is still lacking in the house of the Lord and without which the divine mysteries and the administering of the offices cannot continue. These are chalices, candlesticks, censers, cruets, ewers, caskets for holy relics, crosses, missal covers,79 and all the other things that practical necessity requires for use in ecclesiastical ceremony.

If you wish to make these begin in the following way.

![]()

Chapter 1. The Construction of the Workshop

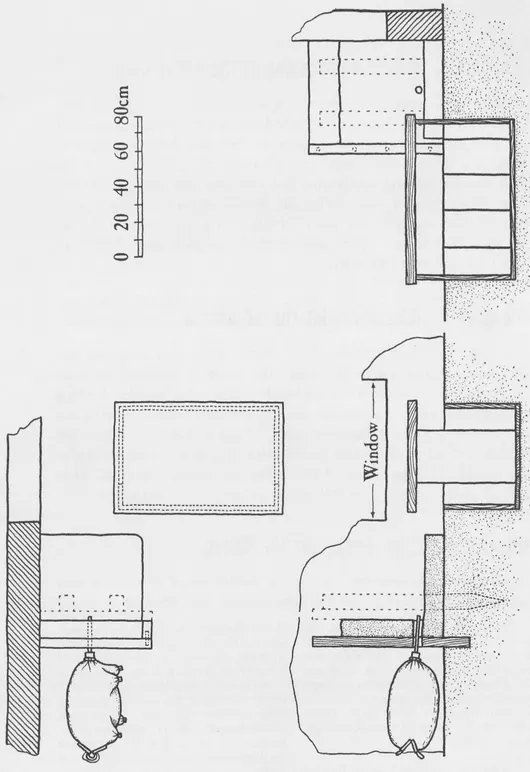

Build a high, spacious building whose length extends to the east. In the south wall put as many windows as you wish and are able to, provided that there is a space of five feet between any two windows. Then, with a wall rising to the top, divide off half the building for casting operations and for working copper, tin, and lead. With another wall divide the remaining half into two parts, one for working gold, the other for silver. The windows should not be more than a foot above ground level and they should be three feet high and two feet wide.

![]()

Chapter 2. The Seat for the Workmen

Then in front of a window, dig a trench, three feet long and two feet wide, a foot and a half from the window wall and at right angles to it. Line the trench all around with wooden boards, of which two in the middle opposite the window should rise half a foot above the trench. On these fasten a table,80 three feet by two, over the trench to cover the knees of the men sitting in it, and at right angles [to them]. The table should be so flat and smooth that any little bits of gold or silver that fall on it can be carefully swept up.

![]()

Chapter 3. The forge81 for the Work

Against the wall near the window on the left-hand side of the man sitting, there should be set into the ground a wooden board three

Fig. 8—Arrangement of the forge and work table in the metal worker’s shop. Translators’ reconstruction

feet long, two feet wide, and almost two fingers thick. When this is firmly in place, it should have a hole in its center, a finger in diameter and four fingers above ground level. There should also be a narrow piece of wood, four fingers wide and as long as the larger board, fitted to it in front and fixed with wooden pegs.82 In front of this, set in position another board of the same width and length [as the first one], so that between the two there shall be a space of four83 fingers, and fix it firmly in place from the outside with two or three stakes. Then take some freshly dug clay, neither kneaded nor mixed with water, and start by putting a little of it into this space and compact it well with a round piece of wood; then put in some more and ram it down again. Continue in this way until two thirds of the space is filled, leaving a third empty. Then take away the board in front, and with a long knife trim the front [edge] and the top of the clay flat and smooth. Then strike the clay hard with a slender piece of wood. After this take some clay that has been kneaded and mixed with horse-dung, and build up the forge and a hearth for it. Coat the wall [of the building] also so that it will not be burnt by the fire. Pierce the clay through the hole at the back of the board with a slender piece of wood. Build all smiths’ forges in this way.

![]()

Chapter 4. The Bellows

Then make bellows out of ram skins in the following way. When the rams are killed, the skins should not be slit under the belly but opened from the rear and turned inside out so that they can be stripped off whole. Then they should be filled with straw and dried out a little. Afterwards they should lie for a day and two nights in a composition of lees and salt. On the third day they should be turned right side out and stretched lengthwise and even more in width. Then they should be greased and stretched again. After this make a wooden head for the bellows to go through the neck and be tied there and then make a hole in the head through which an iron pipe can go. Now, along the width of the bellows at the back, place four pieces of wood, which should be fitted to each other in pairs and tied together in the middle.84 Each pair should be sewn onto the bellows so that the places where they are joined are at the top and bottom of the middle [of the opening in the skin]. At these points also two loops of the same skin should be sewn on, a smaller one at the top to hold the thumb and a larger one at the bottom for the four fingers. When this is finished, put the iron pipe into the hole at the back of the forge, and light a fire of charcoal on the forge and blow, so that the forge is dried out.

The names of the instruments and iron tools used in smith’s work are these:85

![]()

Chapter 5. Anbils [and Stakes]

Anvils that are broad, flat, smooth and square.

Also anvils that are flat, smooth, and horn-shaped.

Also anvils that are rounded on top, like half an apple, one large, one small, and a third short—these are called stakes.

Also anvils that on top are long and narrow, with two horns projecting as from a spear shaft, one of which is round, tapering to a slender tip,86 while the other is broader and slightly curved back at the tip with a smooth roundness like a thumb.87 These should be large and medium.

![]()

Chapter 6. Hammers

Many types of hammer: large, medium, and small, broad on one face and narrow on the other.

Also hammers that are long and slender, round at the tip, both large and medium.

Also hammers that are horn-shaped at the top, and broad at the bottom.88

![]()

Chapter 7. Tongs [and Pliers]

Strong hand pliers having large and small jaws on the end.89

Also long slender tongs.2

2 LIST OF TOOLS NAMED BY THEOPHILUS

Theophilus’ names for the principal tools are given below in Latin with our rendering of them. For particular references see the Index under the English rendering. It should be noted that normally Theophilus uses the medieval masculine form ferrus for a tool, always so in the plural, and the classical Latin neuter form ferrum for an implement made of iron, but he is not consistent.

clavi ferrei: punches for making the heads of studs

cos: hone

cuprum deauratorium: copper gilding tool

cuprum gracile: slender copper tool

ferrum acutum et latius: turning tool (for use with a lathe)

ferrum aequale: burnishing tool (burnisher) ; also used in repousse work

ferrum divisorium: cutting tool (for glass)

ferrum gracile: punch

ferrum grossarium (grosa, grossa): grozing iron

ferrum planatorium: planing tool, drawknife

ferrum solidatorium: soldering iron

ferrum tenue: cutting tool (for wax)

ferrus ad ductile opus: punch

ferrus ad faciendos clavos: tool for making nails

ferrus ductilis: punch

ferrus ductorius: chasing tool (chaser)

ferrus fossorius: engraving tool (graver)

ferrus incisorius: chisel (meizel, p. 148)

ferrus obtusus: burnishing tool (burnisher)

ferrus per quae fila trahuntur: drawplate

ferrus pertractorius: drawing tool, scriber

ferrus punctorius: ring punch

ferrus rasorius: scraping tool (scraper)

filum ex auricalco: brass wire brush

forceps (usually in plural, forcipes): pliers, shears, tongs, tweezers

incus: anvil

incus longa: bick iron

instrumentum iunctorium: cooper’s shaping tool

malleus (dim. malleolus): hammer, mallet

malleus rotundus: pestle

mortarium (dim. mortariolum): mortar

nodus: stake (anvil)

organarium: tool for swaging beaded wire

pila: pestle

pistillum: pestle

runcina: grindstone

serra: saw

setae porci: hog-bristle brush

sigillum: die

subula: awl, scriber, tracer

terebrum: auger, drill

veru: spit

Also long metal-caster’s tongs, slightly curved at the front end.

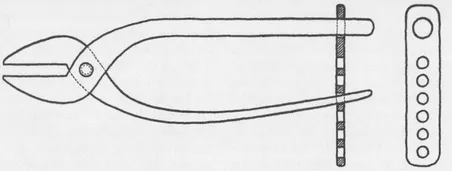

Also medium-size pliers for holding anything that has to be filed. The end of one of the handles of these should be slender, and from the other a wide thin piece of iron, pierced [with a number of holes]90 should hang, and when you put into [the jaws] anything small that is to be filed, squeeze hard, inserting the slender end of the handle into the desired hole.

Also very small tongs [tweezers] joined together at one end and slender at the other, for arranging beads and any other tiny things.

Also tongs known as coal tongs, both large and medium, which are in one piece, bent around at one end and open and slightly curved at the other.

Fig. 9.—Hand vice or spring-handled pliers to hold small wor...