- English

- ePUB (mobile friendly)

- Available on iOS & Android

Modern Manufacturing Processes

About this book

Provides an in-depth understanding of the fundamentals of a wide range of state-of-the-art materials manufacturing processes

Modern manufacturing is at the core of industrial production from base materials to semi-finished goods and final products. Over the last decade, a variety of innovative methods have been developed that allow for manufacturing processes that are more versatile, less energy-consuming, and more environmentally friendly. This book provides readers with everything they need to know about the many manufacturing processes of today.

Presented in three parts, Modern Manufacturing Processes starts by covering advanced manufacturing forming processes such as sheet forming, powder forming, and injection molding. The second part deals with thermal and energy-assisted manufacturing processes, including warm and hot hydrostamping. It also covers high speed forming (electromagnetic, electrohydraulic, and explosive forming). The third part reviews advanced material removal process like advanced grinding, electro-discharge machining, micro milling, and laser machining. It also looks at high speed and hard machining and examines advances in material modeling for manufacturing analysis and simulation.

- Offers a comprehensive overview of advanced materials manufacturing processes

- Provides practice-oriented information to help readers find the right manufacturing methods for the intended applications

- Highly relevant for material scientists and engineers in industry

Modern Manufacturing Processes is an ideal book for practitioners and researchers in materials and mechanical engineering.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Part I

Advanced Forming Processes

1

Advances in Stamping

1.1 Introduction

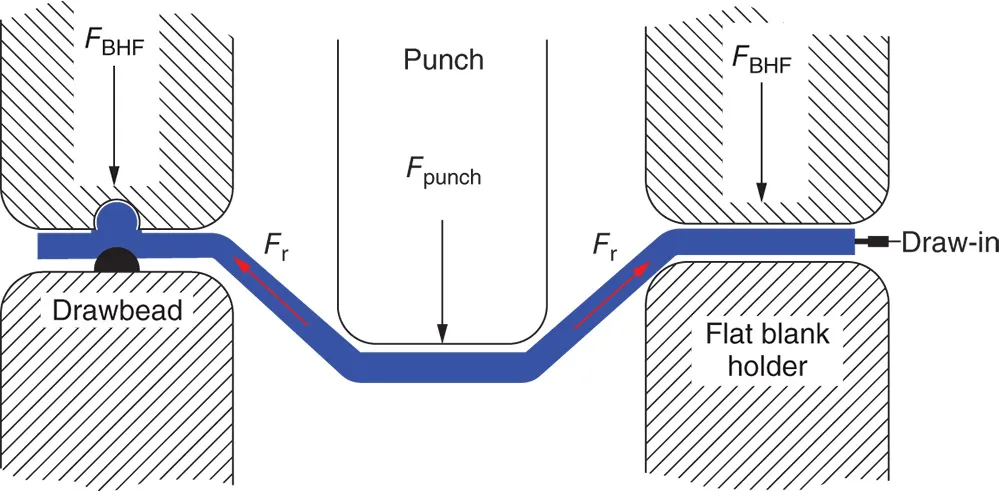

1.1.1 Blankholder and Drawbeads

Table of contents

- Cover

- Table of Contents

- Foreword

- Part I: Advanced Forming Processes

- Part II: Thermal and Energy-assisted Manufacturing Processes

- Part III: Advanced Material Removal Processes

- Index

- End User License Agreement

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app