eBook - ePub

Advanced Functional Textiles and Polymers

Fabrication, Processing and Applications

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Advanced Functional Textiles and Polymers

Fabrication, Processing and Applications

About this book

This book on advanced functional textiles and polymers will offer a comprehensive view of cutting-edge research in newly discovered areas such as flame retardant textiles, antimicrobial textiles, insect repellent textiles, aroma textiles, medical-textiles, smart textiles, and nano-textiles etc. The second part the book provides innovative fabrication strategies, unique methodologies and overview of latest novel agents employed in the research and development of functional polymers.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Chapter 1

Flame Retarded Cotton Fabrics: Current Achievements, Open Challenges, and Future Perspectives

Giulio Malucelli

Politecnico di Torino, Department of Applied Science and Technology, Alessandria, Italy

Email: [email protected]

Abstract

Among cellulosic textiles, cotton is the most utilized, thanks to its peculiar characteristics (including softness, hygroscopicity, excellent breathability, comfortableness, biodegradation, and good thermal conductivity, among a few to mention). However, cotton burns very easily when it comes in contact with a flame or is exposed to an irradiative heat flux: as a consequence, this negative effect remarkably confines the possible exploitation of this material, particularly referring to those application sectors where flame retardant fibers and fabrics are a prerequisite. In this context, the academic and industrial work has been extensively focused on improving the flame retardant behavior of this cellulosic material. Among the different possible solutions, the so-called surface engineering represents a suitable and efficient strategy for conferring flame retardant properties to cotton: in fact, this approach allows the deposition of fully inorganic, fully organic, or hybrid organic–inorganic protective coatings on the fiber/fabric surface. In doing so, the heat and mass transfer phenomena occurring during the fire stages can be remarkably limited: in particular, the structure and composition of the deposited coatings play a key role in the formation of a protective layer on the textile substrate, thus conferring the envisaged flame retardant properties to this latter. From an overall point of view, the surface engineering approaches mainly involve sol–gel processes and layer-by-layer architectures. In particular, the sol–gel technique, which is a very well consolidated approach for the fabrication of ceramics, has started to be exploited also in the textile field because of its advantageous characteristics: among them, it is easily applicable to even irregular substrates as fibers and fabrics, it can be carried out using the already existing industrial finishing lines (such as impregnation/exhaustion units), and it is very efficient in providing the treated substrates with flame retardant features. Besides, the layer-by-layer approach, though it has been well established practically at a lab-scale only, shows some interesting potentialities in a view of a possible scale-up. In addition, very often, the aforementioned techniques allow providing the processed fibers/fabrics with more than one functionality: more specifically, the scientific literature well highlights the possibility of conferring antibacterial/antimicrobial features, low surface tension, and electrical conductivity, apart from the flame retardant properties. Finally, sol–gel and, sometimes, layer-by-layer architectures (the latter depending on the presence of reactive functional groups in the deposited assemblies, which can permanently link the layers to the fabric substrate) can ensure washing fastness to the treated fabrics, which is very often a requisite for a wide number of applications.

This chapter aims to review the state of the art and the still open challenges related to the design of effective flame retarded cotton fabrics. In particular, the current achievements in flame retardancy, specifically involving nanotechnology and surface engineering, will be thoroughly described, highlighting the present limitations and some possible further improvements.

Keywords: Cotton, flame retardancy, surface engineering, sol–gel processes, layer-by-layer architectures, intumescent coatings, superhydrophobicity, washing fastness

1.1 Introduction

Cotton is the most well-known cellulosic material: it possesses such properties as strength, durability, flexibility and air permeability, as well as good biocompatibility, low cost and good mechanical behavior. About 60% of the world’s total cotton harvest is employed for clothings, the rest being utilized for home furnishings and industrial products (i.e., tents, car tire cord, fishnets, and book bindings). At variance, if not flame retarded, cotton, as most of the textile products, is easily flammable: in fact, it burns vigorously, leaving a negligible residue. The annual U.K. fire statistics document that a considerable percentage of the fire incidents occur in domestic environments and involve nightwear, bedding and upholstered furniture [1].

In order to overcome this limitation, since the 1950s, both academics and industrial companies have designed and developed efficient flame retardants (FRs), aiming at reducing the risk of fire: in fact, they are able to decrease the ease of flammability of textiles by lowering the propensity of the material to ignite or slowing down the flame spread rate when needed.

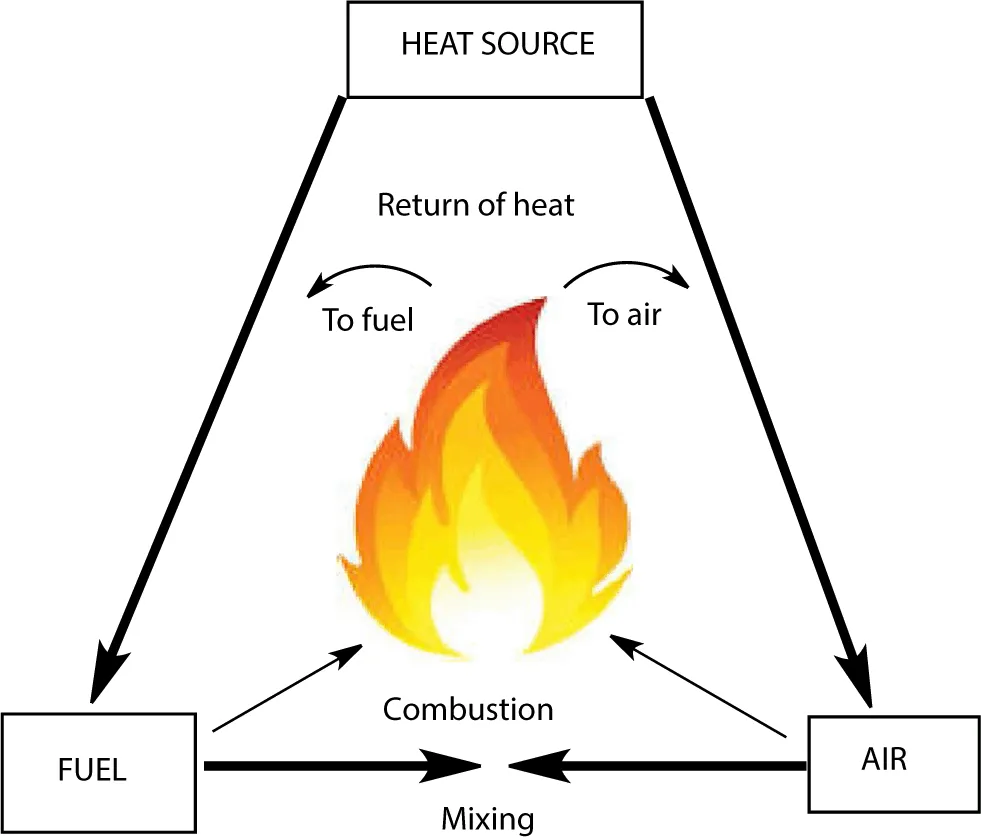

From an overall point of view, flaming combustion, which occurs in the gas phase, is an oxidation reaction and requires oxygen (or air) supply from the surrounding atmosphere. Flaming combustion is a consequence of the degradation of the material with the formation of combustible gases; the latter mix together with atmospheric oxygen, hence promoting a self-sustaining combustion exothermic process, as depicted by Emmons’ fire triangle [2] (Figure 1.1). The combustion reactions can proceed as long as there is enough oxygen (air) and fuel and if the temperature is high enough; if one of these three conditions lacks, fire propagation stops. Besides, either an adequate fuel/oxidant ratio or enough energy to be provided to the system is necessary in order to reach and then overcome the activation energy of the combustion process.

Figure 1.1 Emmons’ fire triangle.

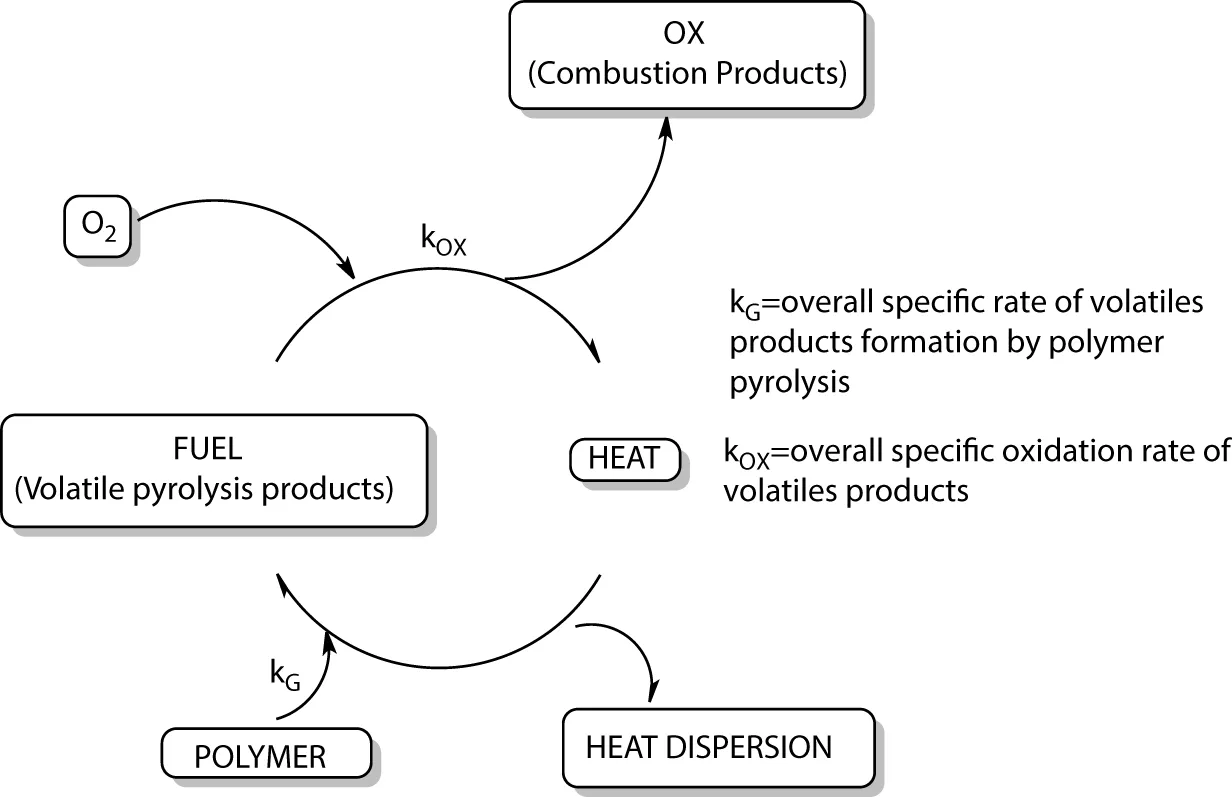

Very recently, a different approach, called “Fire loop”, which describes the polymer combustion, was proposed [3]. The loop (Figure 1.2) emphasizes the cyclic connection that takes place between the two sequential pyrolysis and oxidation reactions involved in the fire event, which determine the overall combustion process, highlighting a particular kinetic interdependence of the two reactions.

Figure 1.2 “Fire loop”.

Basic chemical kinetics states that the rate, at which a product deriving from two linearly connected consecutive reactions is produced, strictly corresponds to the rate of the slowest process. Conversely, in the Fire loop, the two sequential pyrolysis and oxidation reactions exert an effect on each other: in particular, the rate of polymer pyrolysis affects the oxidation–combustion rate through the formation of volatile species, which in turn affects the pyrolysis through the feedback of the combustion heat.

Flame retardants (FRs) are able to delay and even stop the self-sustaining combustion process of the textile materials; according to their structure and chemical composition, they can act either in condensed or gas phase. In addition, the overall effects on either burning rate reduction or on the extinction of the flame are also dependent on the chemical composition and on the thermal and fire characteristics of the textile materials [4–6].

Besides, any of the FRs available on the market or specifically designed for scientific purposes may contain such elements in their molecule, as halogens, metals, boron, phosphorus, sulfur, nitrogen, or a combination of them. The flame retardant can be embedded in the synthetic fibers during the spinning processes or can be covalently linked to the fibers, exploiting grafting or copolymerization reactions. Another possibility involves the application of FRs as surface treatments (i.e., the so-called surface-engineering or surface-engineered approaches), which exploit either the impregnation of the textiles in solutions/stable suspensions containing the flame retardant additive (i.e., a standard finishing treatment), or the coating of the textile substrate with a continuous or discontinuous layer/film on both outer and back surfaces.

In doing so, if these treatments are very effective in providing the textile material with flame retardant features, several outcomes should be attained:

- – the heat developed should be lower than that necessary for sustaining the combustion process;

- – the textile pyrolysis should be addressed toward the formation of a carbonaceous residue (i.e., char) in condensed phase, hence limiting the formation of flammable products that can fuel the combustion;

- – the flame should be separated from the oxygen/air source;

- – on the basis of the chemical composition of the flame retardants, chlorine or bromine atoms, which act as flame inhibitors in the gas phase, should be released as the textile material approaches its ignition temperature;

- – the heat flow back to the textile substrate should be lowered, hence limiting the occurrence of additional pyrolysis reactions, which can give rise to gaseous flammable products;

- – in the condensed phase, upon exposure to a heat flow or a flame, the formation of a barrier, generally made of a coherent char or an intumescent protective coating, should be preferred.

Some halogenated flame retardants as polychlorinated biphenyls and pentabromodiphenyl or decabromodiphenyl ethers [7–9] were found toxic or even mutagenic and therefore they have been banned from the market (even some directives from the European Community have been made and shared with all the European countries); this issue stimulated the scientific and industrial world toward the seeking for less toxic products with low environmental impact. As a consequence, phosphorus-based (even in combination with nitrogen) flame retardants have been identified as suitable alternatives for replacing halogenated flame retardants [10, 11].

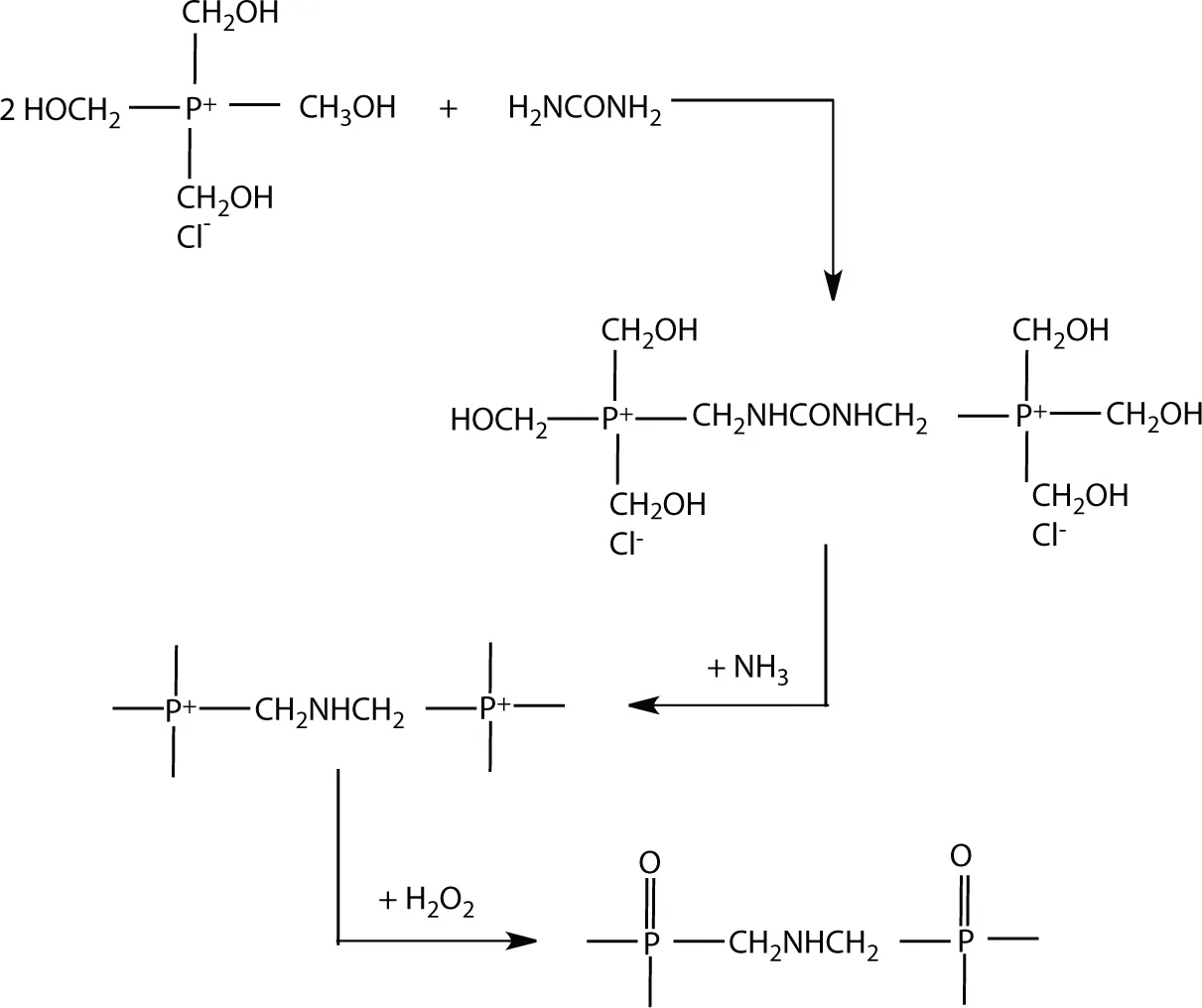

In parallel, the flame retardancy of cotton and of other cellulosic-rich substrates has been significantly improved by either designing efficient halogen-free flame retardants for coatings and back-coated textiles (these efforts have been made from academics mainly), or by using N-methylolphosphonopropionamide derivatives (Pyrovatex®) or hydroxymethylphosphonium salts (Proban®). The latter are “standard” commercially available flame retardants that, apart a high FR efficiency, show significant drawbacks and limitations: in particular, the Proban®process (schematically depicted in Figure 1.3) requires a specific plant for stabilizing the treated fabrics; in addition, there may be the release of formaldehyde during the fabric use [12].

Figure 1.3 Scheme of the Proban® process.

As far as Pyrovatex® is considered, its process (schematically depicted in Figure 1.4) allows permanently anchoring just about 50% of the flame retardant product to cotton substrates: all the rest is lost during the first laundry occasion...

Table of contents

- Cover

- Title Page

- Copyright

- Preface

- Chapter 1: Flame Retarded Cotton Fabrics: Current Achievements, Open Challenges, and Future Perspectives

- Chapter 2: UV Protective Clothing

- Chapter 3: Potential of Textile Structure Reinforced Composites for Automotive Applications

- Chapter 4: Biotechnology Applications in Textiles

- Chapter 5: Environmental Issues in Textiles

- Chapter 6: Water Saving Technologies for Textile Chemical Processing

- Chapter 7: Photocatalytic Dye Degradation Using Modified Titania

- Chapter 8: Advanced Approaches for Remediation of Textile Wastewater: A Comparative Study

- Chapter 9: Polymer-Supported Nanocomposite-Based Nanomaterials for Removal and Recovery of Pollutants and Their Application in Bio-Electrochemical System

- Chapter 10: Reactive and Functional Polymers

- Chapter 11: Fabrication and Biomedical Applications of Polyvinyl-Alcohol-Based Nanocomposites With Special Emphasis on the Anti-Bacterial Applications of Metal/Metal Oxide Polymer Nanocomposites

- Chapter 12: Preparation, Classification, and Applications of Smart Hydrogels

- Chapter 13: Potential Applications of Chitosan Nanocomposites: Recent Trends and Challenges

- Chapter 14: Use of Polymer Nanocomposites in Asphalt Binder Modification

- Index

- End User License Agreement

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Advanced Functional Textiles and Polymers by Shahid Ul Islam, B. S. Butola, Shahid Ul-Islam,B. S. Butola, Shahid Ul-Islam, B. S. Butola in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Materials Science. We have over one million books available in our catalogue for you to explore.