![]()

CHAPTER 1

THE THICK OF IT

During the 1980s, most of the RAF’s Harrier Force was based at Gütersloh in West Germany, just minutes of flying time from the inner German border, which marked the start of Warsaw Pact territory. The two squadrons, 3(F) Squadron and IV(AC) Squadron, were each bigger than 1(F) Squadron in Wittering, having incorporated the assets of 20 Squadron on moving forward from Wildenrath. Life on the Gütersloh squadrons was dominated by the Cold War and the proximity of the perceived threat. When the border between the two parts of Germany was opened up in November 1989, and all of Germany was reunified in October 1990, that was all to change.

Having developed from the Wildenrath days, the Harrier concept of operations in Germany in the 80s was based on dispersal of the aircraft to temporary sites spread over a wide area, making them difficult to locate and to attack. Each squadron had three flights, each of which had its own flying site. In addition, there was a logistics site for each squadron, supplying fuel, weapons and spare parts as necessary. The sappers (Royal Engineers) who did the site preparation had their own resources park where they stored the materials to build operating surfaces, fuel storage and aircraft hides. Providing control and coordination for all of these was the Forward Wing Operations Centre (FWOC), giving ten active sites at any time. The sappers would normally have two more flying sites ready for use in case a site became compromised. It was anticipated that sites might need to move as often as every 48 hours. Ground defence was provided by an RAF Regiment field squadron, while all deployed personnel were armed for self-protection. The second vital army asset to make the concept workable was the Royal Signals, who provided communications between the sites and out to the tasking agency. Generally, tasks would come from the NATO HQ in the caves at Maastricht in Holland, though this function could be delegated to HQ 1 (BR) Corps, for whom the Harriers mostly provided support. Air traffic controllers also deployed to each site, but their job was unusual in that flying operations were conducted in radio silence, to avoid revealing site locations, unless flight safety required an intervention.

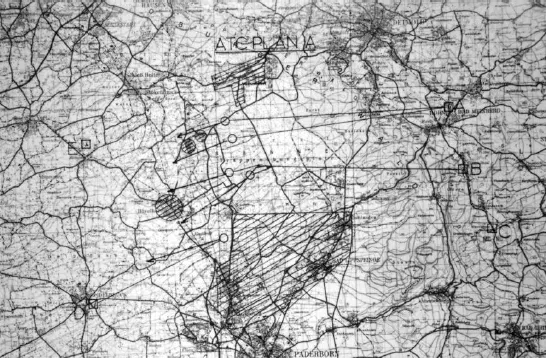

On each flying site, there were eight hides, able to accommodate the six aircraft of the deployed flight, plus two spare hides to be used by aircraft diverted during a site move. Each time a new flying site was activated, a modified air traffic plan was issued from the FWOC, showing departure lanes, initial points (IPs) and sites. For a pilot, recovering to a field site was always a challenge. All military pilots are taught to find a target by flying accurately from an IP, which would be chosen as a feature easily identifiable from the air, to a target at a constant speed. However, for recovery to a field site, a Harrier pilot would start the run at 420kts and end it in the hover over the pad. With the site camouflaged to make it difficult for enemies to find, and operating in radio silence, this was a tricky procedure.

Simple air traffic plan with just five flying sites. (Author)

Identifying potential sites was a continuous process carried out by the Harrier Plans staff. The prime requirements for a flying site were fairly level and firm surfaces for a take-off strip of some 200 metres, a square landing pad, and the aircraft hides. The pad would be a MEXE pad constructed by the sappers using PSA1 material. The strip would often be made of this same material, necessitating the sapper ritual of ‘kicking tin’ to go on for rather longer, or for a short period, the natural surface could be used, if its hardness (CBR) was sufficient, as tested by the ‘pogo stick’ or cone penetrometer. Any local deficit in hardness would often lead to the Harrier ‘bogging in’, typically with the nosewheel sinking in far enough to prevent further movement. Ground crew became very skilled at extracting jets from such situations, digging a ramp in front of the wheel before as many people as possible climbed onto the tailplane while a Unimog, or if more weight was needed for grip, a three-ton Bedford truck, pulled on the towbar. In extreme situations, usually after heavy rainfall, a metal skid device could be attached to the nosewheel to prevent it sinking beyond the axle while it taxied to the take-off strip. The skid was removed before departure. The potential bog-in embarrassment factor for the pilot was increased by a design feature of the GR3, whereby a footstep to assist access lowered as the canopy opened. However, if the aircraft bogged in far enough, the canopy could not be opened until a hole had been dug for the footstep to go down into. To maintain the necessary level of expertise, field deployments were usually practised three times a year.

The qualities of sites varied a lot, from a new autobahn in one case, to the trickiest of grass strips. Often, the strip length was such that there was no option to abort the take-off on the strip once the engine had reached full power; if anything went wrong after that, ejection was the way out. One strip that sticks in my mind was in the Bergen-Hohne training area. We had moved site overnight, and after diverting to other sites, I and five other pilots flew into the new site early in the morning. We had a look at the take-off strip, which was not very long and pointed towards tall trees, and were reassured that all the calculations showed that it would be safe. However, the standard calculations appeared not to make sufficient allowance for gradient, and this strip was distinctly downhill. With a new task planned, I was the first to take off. I was told later that my jet blast parted the tree tops sufficiently for me to miss them. The next pilot out was not so lucky. He collected some foliage in his undercarriage, which he left down as he flew to the diversion airfield. All further tasking was cancelled, the remaining jets were defuelled to a light weight, and the site was abandoned.

The challenge of a first field deployment is described below by Keith Marshall. Keith Grumbley admits his error in the account that follows, as does Gerry Humphreys in the third story.

KEITH MARSHALL

It was my first deployment with 4 Squadron. I was an experienced pilot with more than 2,000 hours but very new on the Harrier and what I am about to tell you does me no credit, but exemplifies the complexity of the aircraft I was now assigned to fly and the equally demanding environment in which to operate it.

I was not trusted to fly in with the big boys and instead went to our operating base, Eberhard in the Sennelager military training area, with the ground party. The weather was very poor for the first five days with thick fog preventing the arrival of the jets and I kept thinking how nice it must be to still be on base, going home each night to a warm cuddly wife instead of enduring the joys of a damp ‘green worm’ sleeping bag. Sometimes life gets unbearably tough so we, the boss, the engineers and several of the lads sought solace in the local strip club (funny how these things always pop up around barracks) which was quiet at the time and more than happy to give us its undivided attention and lots of excellent beer.

On the morning of the sixth day the fog cleared enough to allow the jets to fly in and so with a splitting head I watched with awe as they arrived; then the fog came mockingly back, preventing any more activity that day. The flyers were most impressed with our thorough reconnaissance of the local locales and insisted that we take them for a personal look, and so it was that when the next day unexpectedly broke crystal clear, the last thing we really wanted was to put a bone dome on our aching heads. But queen and country call, and we briefed, grabbed our kit and I set off for my first flight from a deployed site.

This particular site had a stretch of road (open to traffic except during take-off or landing) of about 300 yards for take-off with what looked to me like extremely tall and hard pine trees immediately off the end of the runway. The normal procedure was to use water, injected into the rear of the combustion chamber to give an extra boost for take-off and for the vertical landing. A full tank was enough for 90 seconds and weighed about 500 lbs. On arrival at my jet, the crew chief told me that the water system was unserviceable; no sweat, I’d been briefed that a waterless departure was perfectly OK at this particular location provided, of course, the water tank was empty. I’m sure you know what’s coming; the tank was not empty and I was so nervous of making a mess of things that it was precisely what I did. The water contents gauge was right in front of my face and indicating full but I did not see it. In mitigation, everything was a bit rushed and in what seemed like seconds I was out of the hide and onto the road.

The usual checks were completed and off I went for my first deployment take-off, which came uncomfortably close to being my last. Even without water flowing and with an extra 500 lbs of weight, the Harrier acceleration is pretty impressive, but not impressive enough for my liking with those big, hard-looking trees getting ominously close. It was beginning to dawn on me that something was not quite right but it was too late to abort, I just had to hang in there and hope. At the pre-computed speed I rotated the nozzles and the nose at the same time but those trees were still filling an awfully big part of the forward cockpit window. I kept rotating, probably exceeding the recommended angle of attack limit, but as I went past the trees there were still some branches above the level of my head. I’m not sure, but I think I felt a bump somewhere on the underside of my aircraft.

Surprised at still being inside this tiny cockpit, I lowered the nose with much relief, raised the gear and flaps and scanned the horizon for my leader. There was no time to reflect on what had just happened as in moments the lead and I were engaged by two RAF Phantoms that had been sneakily waiting for us. We managed to shake them off and then flew through the surface-to-air missile (SAM) zone with lots of avoiding action to break the locks as indicated on the radar warning receiver (RWR). Lead called us over to the Forward Air Controller frequency and we started our attack runs. The target was an inflatable rubber tank which when fully erect (so to speak) looked like a Russian T62. On this morning however, it was looking much as I felt, half deflated, with its protruding rubber gun barrel drooping like a sad little worm hanging over the edge of a table.

Back through the SAM belt to find the Phantoms still lurking on the other side, we quickly saw them off and headed for our temporary home. Now comes the tricky bit: trying to find one’s site when it is specifically designed not to be found from the air. I decided to follow my leader and started the deceleration about two miles in trail. He made it look easy and I was feeling pretty confident that I could accomplish a vertical landing onto the pad with every bit as much panache as he had done. There was just one small problem: to hover, the Harrier needed to be below a certain fuel weight and the trick was to get below that weight but still have enough fuel to divert if necessary. (As experience and expertise grew, most Harrier pilots would start their deceleration above that critical weight and arrive above the pad, in the hover, fractionally below it.) It usually meant getting into the hover with about 600-800 lbs of fuel. Now, remember that extra 500 lbs of water that I did not think I had?

Everything was going fine until I realised I had the nozzles down with full power and still some wing lift. I decided to go round again to burn off a bit more fuel, thinking that my hover weight calculations must have been a bit off. It would mean going below fuel minimums but I was the last airborne and there was therefore no reason to have to divert. I figured that if I was going to crash, it might as well be on my own site.

The next approach got me into the hover with just about enough fuel to land. The only problem now was that I had full power on the engine and the jet was going down. There was nothing left, I was sinking into the trees but luckily somewhere over the pad. There was no chance to do the customary pause at 50 feet and make corrections. I was committed for better or for worse. Lucky for me, it was for better. I taxied to the hide and at last had a chance to think. It was then that I saw the water contents gauge and cringed inside my shell.

KEITH GRUMBLEY: JÄGERGRUND (LOOKING AFTER THE LAWN)

Harrier operations off grass-field sites were not uncommon during the halcyon years of the RAF Germany Harrier Force. We did them for three reasons: the aircraft could do it, there were seldom enough conventional field sites (either road or metal alloy ‘tin’ strips) and it was 21 another challenging dimension to the force’s capability. Let me explain.

Grass runway. (Dave Morgan)

Rules of thumb came into play when selecting a grass site. The surface smoothness was deemed OK if you could drive a Land Rover over it at 40 mph and maintain control. The surface hardness was measured by a spring-loaded pogo stick jabber which gave a reading at various depths. For us a reading of three at six inches was generally OK although heavy rain degraded the soil structure leading to much effort and swearing when the site had to turn out to extricate bogged-in Harriers. One became pretty adept at eyeballing the length of strips and the 10° obstacle clearance criterion, but these were confirmed by the Harrier operating manual.

Take-off and obstacle clearance assumed that the engine was performing at full poke, that flaps were down and that the correct climb-out angle was achieved by easing back on the stick at lift-off. Regardless of the Land Rover check, the vibration during take-off rendered the instruments an illegible blur. The take-off, or nozzle rotate, point was therefore marked with an orange peg at a position calculated to take account of aircraft weight, engine thrust rating, wind, ambient temperature and pressure. The marker would be moved during the day as conditions changed, but for simplicity the heaviest site aircraft and the worst site engine were used in the calculation.

Harrier exhaust eroded and burnt grass surfaces very quickly so special techniques were applied. These involved some changes to normal procedures to minimise time on the ground and so everything from engine start-up onwards was done at the double. If the field was big enough, the start point for the take-off roll would be moved around to spread the wear. If you failed to keep the site operational for the full two weeks of the deployment, you were automatically the poor sods nailed for a site move. Thus it was up to everyone to facilitate a highly slick operation.

The short time from start-up to take-off necessitated the quickest romp through the checks to get out of the hide without blowing all manner of dust and crap into the site, and over your colleagues’ jets. Out of the hide you raced through the pre-take-off vital actions and did a quick acceleration check to ensure that the engine was going to wind up as advertised. During this run up to 55% you needed to check that the engine inlet guide vanes were operating correctly, and pull in a quick dab of nozzle to check that reaction control ducts were pressurizing to give you control between the 70-odd knot lift-off speed and reaching conventional flying speed. These two gauges were inconspicuous little blighters, adversely commented on early in the jet’s life, but never improved.

Check instruments: reaction control duct pressure gauge. (Author)

Finally, as you turned onto the strip for the rolling take-off it was essential to select the flaps down. Air traffic control was always situated to give a good view of the take-off and they were under no illusions about their responsibility to break radio silence should they doubt the flap selection. The engines were reliable and would respond willingly, which left the human action of selecting flaps down at a time of great distractio...