![]()

PART ONE

WHY YOUR COMPANY NEEDS HIGH VELOCITY INNOVATION

![]()

CHAPTER ONE

WHY INNOVATION PROGRAMS TAKE TOO LONG

On September 2, 2015, Elon Musk announced on Twitter that Tesla was moving out of the margins and into the mainstream of the car industry. The Tesla 3 would be the company's first car for the masses, with a price comparable to a low-end luxury car. It would incorporate all the innovation that Tesla was known for and it was expected to revolutionize the car industry.

When the first one rolled off the line in July of 2017, Tesla had a backlog of 455,000 orders to fulfill. However, the company missed its first production target. And then missed the second. As months passed, one problem after another plagued production.

Savvy consumers know that production problems at launch often mean quality problems later. In March of 2018, Tesla recalled half the cars it produced for a steering wheel repair. The backlog of Tesla 3 orders gave Tesla some buffer to address the problems, but the markets were not so forgiving. Tesla's stock dropped from a peak of $383 per share in June of 2017 to a low of $252 in April of 2018.

The company's iconic reputation for innovation and Elon Musk's credibility as one of the most innovative persons in the world came under serious threat. No one doubted that the Tesla 3 was innovative, but now the execution failures would blunt the impact this innovation would have on the car industry.

How did this happen to one of the most innovative companies in the world? As Elon Musk said in an interview for Bloomberg News in July of 2018, “We were huge idiots and didn't know what we were doing.”1

Innovation Management Is Counterintuitive

Effective innovation development is the ability to drive an innovation to completion, whether it's a new product, process, or business model. Yet innovation management is counterintuitive because common assumptions about management tend to break down in environments of high uncertainty. This means the things that teams do to speed up innovation often slow it down.

At Tesla, Musk had designed the Tesla 3 and its production process on the assumption that the factory would be as fully automated as possible, and then jumped with both feet into building a fully automated factory. Yet that meant incorporating a lot of unproven ideas about how to automate manufacturing all at once before the product had been stabilized and proven.

Tesla invested hundreds of millions of dollars in robots that sat idle after it became clear that people could do the same thing with less cost, time, and quality problems. They made a lot of costly decisions without the knowledge to make those decisions, and paid dearly for it in reputation, market capitalization, and consumer confidence. Although Tesla's struggles were the ones that made the newspapers, many Innovation Program Leaders deal with these same issues behind the scenes while trying to do their best to go as fast as they can.

Innovation Program Leaders Try to Do the Right Thing

It seems like the best thing to do with a new business idea is to run it by some customers to get reactions and then make decisions based on their feedback. But customers are notoriously bad at providing accurate feedback on something that's in the conceptual stage. Most customers can't give good information about a new idea until it is made more concrete with a representative sample of the final product. And in some industries, like food and beverage or medical devices, it may not be possible to give customers representative samples for something that has never been done before, for safety reasons.

In product development, it seems right to define all the requirements up front and then drive them into execution with a streamlined development process. However, that assumes teams have good information, and that's not possible to get so early in the program. If the execution team assumes that requirements are frozen and acts accordingly, then changes to requirements become expensive rework loops. For innovation programs, the requirements change often as new information comes in.

Innovators deal with a lot of uncertainty, and it seems like making bold decisions early is one way to reduce the amount of turbulence. But those bold decisions are the ones that lead to major failures like the production process for the Tesla 3, that trigger massive delays and cost overruns, if the product survives at all. Instead of accelerating innovation, they slow it down.

The Things People Do to Speed Up Innovation Slow It Down

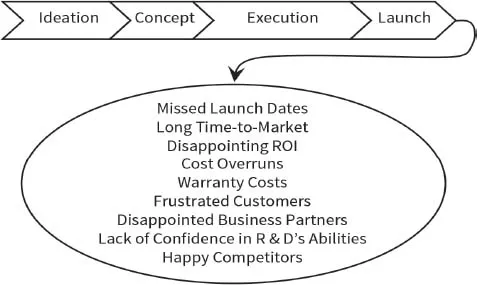

Over and over again, I see the things company leaders do to accelerate innovation often slow it down instead. They encourage teams to be decisive, only to find that many of those decisions have to be revisited later, when it's expensive to change the decisions. They accelerate the Investigation Phases of innovation to meet an aggressive time line, and then find that the Execution Phases get bogged down. They staff an innovation team with outsiders for fresh thinking and then wonder why these teams' products cost too much or fail to resonate with consumers. Figure 1.1 shows the problems that people experience over and over when they try to push innovation.

Figure 1.1: Disappointing results from innovation.

Three practices in particular receive a lot of praise in innovation management literature. They have been around long enough that if they had a lot of success, they'd be much more common with many innovations in the market that would demonstrate their value. Although a lot of theory has been written about them as compelling hypotheses, they don't have much evidence to prove them.

Skunkworks

Conventional wisdom says that if a company's people are not innovative and the processes and metrics conspire to kill innovation, the best thing to do is to get it completely out of the building. “Skunkworks” refers to a team that has been deliberately isolated from the company's core and told to “do all the new things we can't do” or “start with a blank sheet of paper.” Figure 1.2 shows how isolated they are from their peers in the business.

They're usually located in a remote building or an independent space rather than sitting with their Engineering and Marketing peers. Some innovation authors write as if this idea is a new discovery, but that's where storied innovation engines like PARC, HP Labs, and Bell Labs came from.

There's a reason why these entities have become shadows of their former selves: they were not very effective at delivering innovations that their sponsoring companies could implement, and therefore they became targets for funding cuts. PARC's best inventions, the mouse and the touchscreen, were exploited by Apple, not Xerox. Bell Labs spun out a few successful companies when the parent company was willing to support them, but the breakup of AT&T also broke up their funding for such wide-ranging research. HP Labs incubated a lot of ideas throughout the decades while the founders were still alive and able to keep the teams focused. After they retired, funding evaporated as a series of downsizings and management missteps led to the need to shore up shareholder results.

Figure 1.2: Skunkworks teams are isolated from the current business.

Even the more recent examples are just as likely to show spin-offs or killed ideas rather than new initiatives that truly create value for the companies that sponsored them.

It turns out that companies, especially the large, well-funded companies that can afford skunkworks teams, have powerful immune systems. Since the people in such efforts are cut off from the rest of the organization in every way but funding and a tenuous connection to leadership, there is no home for the innovations when they come back into the company.

Either these teams develop into standalone entities that are ripe for being cancelled, sold off, or spun off, or they might as well. They have nothing in common with the parent company. At some point, the investment stops making sense. All their management sponsors have to do is change the strategy or leave the company, and all that investment gets put to waste.

Specialist Innovation Teams

Even worse are the proponents of assigning responsibility for innovation to a specialist team, mainly consisting of people brought in from outside the company. At least most companies staff skunkworks teams with experienced people. The Innovation Specialist approach is fun for the people on the innovation teams because they are freed from much accountability or need to learn about their new company, and encouraged to do things that are dramatically different than the corporate norms. But it doesn't ensure that the teams will get better results and the track record backs that up.

Figure 1.3: Dedicated innovation teams push irrelevant ideas.

This approach seems to be especially popular with those who study innovation practices academically, who base their hypotheses on the observed externalities of innovation programs. Like skunkworks, these programs don't have a good empirical record of success. In fact, such teams can become deaf to valid constructive criticism from the company's experienced personnel, who may have good points even though they appear to be resistant to change. Figure 1.3 shows that the information flow from such teams to the current business tends to be a one-way push.

On the other side, it sends the wrong message to everyone else: “You're part of the past but not the future, and as such, you have no responsibility to be innovative.” Some people will love the freedom to pursue an undemanding status quo and others will chafe at the restrictions; either way, the company is not getting the best from its most deeply knowledgeable people.

Startup Innovation for Corporate R&D

Finally, many innovation team leads like the idea of “going back to the garage” and embracing the methods that allow startups to become multi-billion-dollar businesses. But a corporate innovation team, even in a small established company, has both strengths and weaknesses that a startup doesn't have.

In Chapter 3, you'll read about some aspects of Lean Startup that translate well into corporate innovation programs, but these tools are not dependent upon building a startup culture. Today, people who want to work in startups have ample opportunities to work for one or even start one. Even there, the heavy workload is not sustainable and burns people out.

The people who work in a corporate environment have chosen to work in a place with more constraints and stability but fewer sacrifices, but that doesn't mean they lack good ideas. Such an approach almost ensures that people with families, especially but not exclusively women, will be locked out of innovation programs and the career advancement they can foster because the demands will be even heavier.

All of that might be worth it if it delivered better results. Here, the evidence again shows scant progress toward improving the velocity of innovation. Figure 1.4 shows that such a model combines the worst aspects of the skunkworks model and the dedicated innovation team model: the group is “protected” from the current business and exempted from much of the rules, yet they are expected to push ideas onto the rest of the company.

Figure 1.4: “Start-up” teams are isolated and push irrelevant ideas.

I witnessed this firsthand when I was part of the short-lived E-Services Inside Factory at HP Labs. This was an attempt to go “back to the garage” to reinvent how services talked to each other over the Internet, an early form of the API frameworks that drive tools like Zapier. At the time, e-services were a core part of HP's strategy, and the assignment seemed like it would be a lot of fun.

Yet strong executive support led to lack of accountability and the freedom to do anything, which made it hard to get anything meaningful done, and there was no place to c...