- 328 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Workshop Processes, Practices and Materials

About this book

Workshop Processes, Practices and Materials is an ideal introduction for entry level engineers and workshop technicians, as well as engineering university students with little or no practical experience. With detailed illustrations throughout and simple, clear language, this is a practical introduction to what can be a very complex subject. It has been significantly updated and revised to include new material on current Health and Safety legislation, gauging and digital measuring instruments, as well as modern measuring techniques such as laser scan micrometer, co-ordinate and visual measuring systems. A new chapter on an introduction to CNC milling and turning has been added. This book covers all standard workshop topics, including safe practices, measuring equipment, hand and machine tools, metal and plastics materials, joining methods including welding, presswork, primary forming, casting and moving loads, making it an indispensable handbook for use both in class and the workshop. Its broad coverage makes it a useful reference book for many different courses worldwide.

-

- Health and Safety chapter covers current best practice and has been checked by a certified health and safety examiner.

-

- Addition of modern measuring techniques using laser scan micrometer, co-ordinate and visual measuring systems.

-

- Addition of an introduction to CNC milling and turning.

Information

CHAPTER | 1 |

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Dedication

- Table of Contents

- Preface to the first edition

- Preface to the second edition

- Preface to the third edition

- Preface to the fourth edition

- Preface to the fifth edition

- Acknowledgements

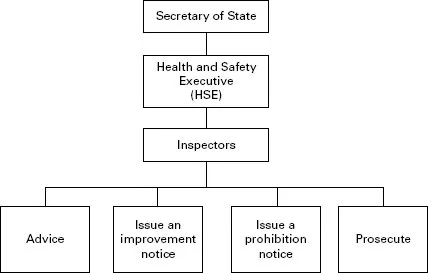

- 1 Safe practices

- 2 Hand processes

- 3 Marking out

- 4 Sheet-Metal operation

- 5 Standards, measurement and gauging

- 6 Measuring equipment

- 7 Cutting tools and cutting fluids

- 8 Drilling

- 9 Turning

- 10 Surface grinding

- 11 Milling

- 12 Introduction to computer numerical control

- 13 Joining Methods

- 14 Materials

- 15 Plastics

- 16 Primary forming processes

- 17 Presswork

- 18 Investment casting, lost foam casting and shell moulding

- 19 Die-casting and metal injection moulding

- 20 Moving loads

- 21 Drawing, specifications and data

- Appendices

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app