- 476 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Liquid Atomization

About this book

Covering the basics of liquid atomization, this book familiarizes readers with the physical processes of liquid atomization, the main types of atomizers and their design, measurements of spray characteristics, experimental investigations of atomizers, and application of atomizers. It demonstrates how to calculate and design atomizers and how to mea

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

CHAPTER

ONE

ONE

INTRODUCTORY CONCEPTS

1-1 VARIOUS METHODS OF LIQUID ATOMIZATION

A device used for liquid atomization (i.e., disintegration of liquid into drops) is most frequently called an atomizer. An atomizer can be an independent device or part of a bigger device such as a diesel injector, furnace burner, spray gun, spray drier, or sprinkle chamber. Atomizers can be used either as individual devices or in groups.

Atomized liquid can be generated in other ways than by using an atomizer. For example, in the carburetor of a carburetor engine or in the low-pressure section of a steam turbine, very small droplets form because of evaporation or condensation. These methods of drop formation will not be discussed in this book.

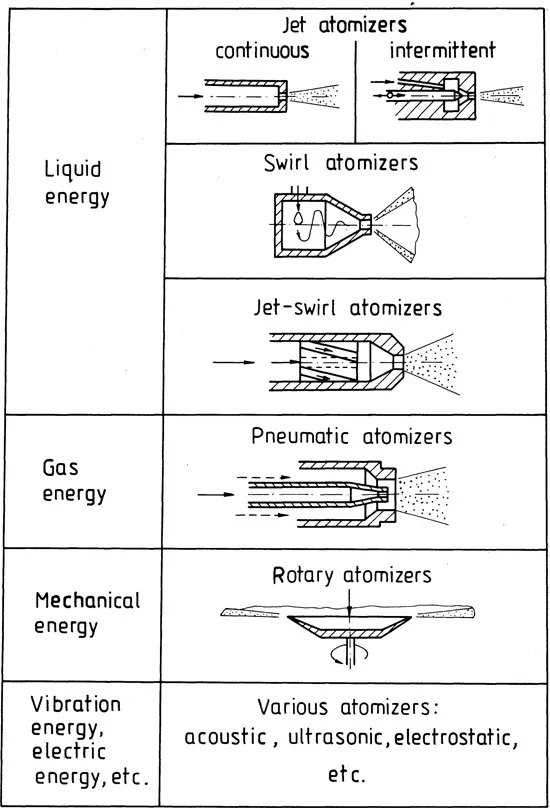

The classification of atomizers [21] can be based on various principles. A classification that takes into account the type of energy used for atomization seems preferable (Fig. 1-1). As can be seen, the sources of energy are very diverse.

The energy most commonly used is that of the liquid itself. The pressure drop is converted in an atomizer into kinetic energy, which leads to atomization of the liquid. This is the principle of operation of pressure atomizers(hydrodynamic) with a simple discharge (jet) or swirl discharge. It is also the rationale for dividing this group of atomizers into three types: jet atomizers, swirl atomizers, and jet-swirl atomizers. Pressure atomizers are more economical than other atomizers when power demand is considered. They are used mostly because of their simplicity, but they are not suitable for atomization of very viscous liquids and their atomization quality decreases with increasing flow rate.

Jet atomizers are divided into two types: continuous (open) atomizers and intermittent (closed) atomizers. Continuous atomizers are the simplest of all atomizers; intermittent atomizers are the most complex in design and technology. These characteristics result from the different types of operation (continuous or intermittent). Continuous atomizers are used in rocket engines, for spray painting, and so forth, and intermittent atomizers are used in diesel engines.

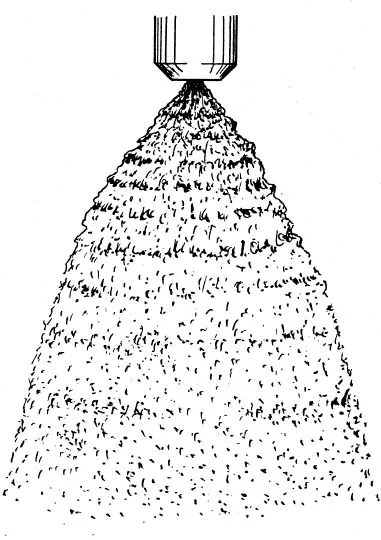

A jet atomizer produces a jet that disintegrates at some distance from the atomizer (Fig. 1-2. The process of disintegration and final effect depend on the type of the liquid, discharge orifice diameter, velocity of discharge, and ambient conditions. For a given atomizer the jet disintegration can be speeded up by increasing the discharge velocity (increasing the injection pressure). To this end, high injection pressures are used; in the case of intermittent atomizers the injection pressures reach tens of megapascals.

Figure 1-2 A liquid jet discharging from a jet atomizer.

Jet disintegration can be speeded up by the development of a flat jet in fan spray atomizers. Such a jet, or in fact a flat film, disintegrates into drops much more easily than a cylindrical jet of the same flow rate. Another way to speed up the disintegration of a cylindrical jet is to have it collide with a solid object (impact atomization). Jet atomizers with two colliding liquid jets are also used to speed up disintegration.

The name swirl atomizer originates from the swirling of the liquid inside the atomizer. These atomizers are divided into several types, each of which generally ensures good disintegration for moderate and even for small pressure drops (small injection pressures). Because of this and their relatively simple design, swirl atomizers are the most widely used of all types of atomizers. Examples of their application include gas turbines, steam attemperators, and air conditioners.

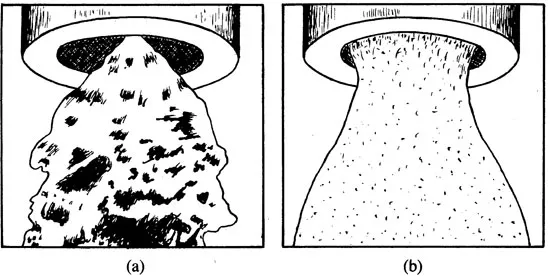

The operation of swirl atomizers is based on the principle that the liquid swirling in the swirl chamber leaves it not as a compact jet but as a conical sheet. The disintegration of the sheet into drops proceeds differently depending on the discharge velocity. For small velocities the sheet disintegration is due to perforation, for higher velocities it is due to wave phenomena, and for very high velocities it is due to aerodynamic action of an ambient gas (Fig. 1-3). In practice, the term liquid atomization is understood to mean the latter case of sheet disintegration.

Jet-swirl atomizers have the combined features of jet and swirl atomizers. This results in a new type of atomizer, in which the distribution of the jet density in the cross section perpendicular to the jet axis can be arbitrarily adjusted according to need. Therefore, one can also obtain a uniform distribution—an advantage in all of these applications, in which one needs the most efficient heat and mass exchange between the drops and the environment. Because of the nature of the combination of two different types of atomizers, part of the fluid flows as an unswirled axial jet and part as a swirled annular jet. The mass and momentum exchange between these jets determines the distribution of the liquid in the transverse cross section and the atomization quality.

Pneumatic atomizers (gas-assist atomizers) use the energy of a gas, usually air or steam. Gas having high kinetic energy ensures good disintegration of jets or sheets of the liquid. Pneumatic atomizers find application in various fields, but are especially useful in the atomization of very viscous fuel oils using steam. Pneumatic atomizers are most complex as far as the flow is concerned, because there is an interaction between two phases, liquid and gas. This interaction can have a parallel, crossing, or swirled direction and the liquid and gas can occur as jets or sheets. In the case of parallel interaction, waves develop on the interaction surface and cause the disintegration of the liquid into drops. In a crossing interaction the liquid disintegrates because of the dynamic action of the gas. In a concurrent or backward swirl interaction, both wave and dynamic phenomena occur [8] (Fig. 1-4). The interaction between jets of liquid and gas in a pneumatic atomizer can take place inside or outside the atomizer.

Figure 1-3 Liquid atomization using a swirl atomizer.

Figure 1-4 Sheet disintegration in an atomizer with whirl flow. (a) Without air flow; (b) with air flow.

Rotary atomizers are most commonly driven by an electric motor and rotate around their own vertical or horizontal axis. The energy of the atomizer is transmitted to the liquid, which causes the liquid to leave the atomizer with high kinetic energy and disintegrate. Under certain conditions this type of atomizer can ensure good atomiz...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Preface

- Nomenclature

- 1 Introductory Concepts

- 2 Theoretical Basis of the Process of Atomization

- 3 Parameters of Atomized Liquid

- 4 Types of Atomizers

- 5 Design of Atomizers

- 6 Experimental Results

- 7 Experimental Techniques and Measuring Devices

- Author Index

- Subject Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Liquid Atomization by L.P. Bayvel in PDF and/or ePUB format, as well as other popular books in Physical Sciences & Industrial & Technical Chemistry. We have over one million books available in our catalogue for you to explore.