- English

- ePUB (mobile friendly)

- Available on iOS & Android

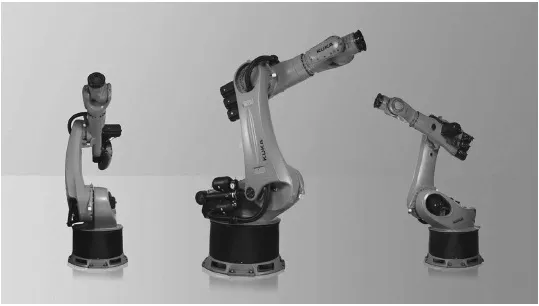

Robot Modeling and Control

About this book

A New Edition Featuring Case Studies and Examples of the Fundamentals of Robot Kinematics, Dynamics, and Control

In the 2nd Edition of Robot Modeling and Control, students will cover the theoretical fundamentals and the latest technological advances in robot kinematics. With so much advancement in technology, from robotics to motion planning, society can implement more powerful and dynamic algorithms than ever before. This in-depth reference guide educates readers in four distinct parts; the first two serve as a guide to the fundamentals of robotics and motion control, while the last two dive more in-depth into control theory and nonlinear system analysis.

With the new edition, readers gain access to new case studies and thoroughly researched information covering topics such as:

? Motion-planning, collision avoidance, trajectory optimization, and control of robots

? Popular topics within the robotics industry and how they apply to various technologies

? An expanded set of examples, simulations, problems, and case studies

? Open-ended suggestions for students to apply the knowledge to real-life situations

A four-part reference essential for both undergraduate and graduate students, Robot Modeling and Control serves as a foundation for a solid education in robotics and motion planning.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

CHAPTER 1

INTRODUCTION

Table of contents

- Cover

- Title Page

- Copyright

- Dedication

- Preface

- Chapter 1 Introduction

- Part I The Geometry of Robots

- Part II Dynamics and Motion Planning

- Part III Control of Manipulators

- Part IV Control of Underactuated Systems

- Appendix A Trigonometry

- Appendix B Linear Algebra

- Appendix C Lyapunov Stability

- Appendix D Optimization

- Appendix E Camera Calibration

- Bibliography

- Index

- End User License Agreement

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app