eBook - ePub

Green Electrospinning

- 354 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

The last two decades have seen electrospinning of nanofibers performed mainly from solutions of toxic organic solvents. The increase in demand for scaling up electrospinning in recent years therefore requires an environmentally friendly process free of organic solvents. This book addresses techniques for clean and safe electrospinning in the fabrication of green nanofibers and their potential applications.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1 Green electrospinning

Nesrin Horzum

Rafael Muñoz-Espí

Institute of Materials Science (ICMUV), Universitat de València, Paterna, Spain

Matthew A. Hood

Max Planck Institute for Polymer Research, Institution is Max Planck Institute for Polymer Research, Germany

Mustafa M. Demir

Department of Materials Science and Engineering, İzmir Institute of Technology, İzmir, Turkey

Daniel Crespy

Department of Materials Science and Engineering, School of Molecular Science and Engineering, Vidyasirimedhi Institute of Science and Technology, Rayong, Thailand

Abstract

In the last two decades, electrospinning has grown in popularity; however, the majority of the setups are based on solution processing from toxic organic solvents. As green processing and environmental stewardship have also become important in recent years, for political and economic reasons, the subsequent increase in demand for the scaling up of electrospinning requires that an environmentally toxin-free process be championed. This book comprehensively addresses clean and safe electrospinning for the fabrication of green nanofibers and evaluates their potential applications.

Keywords: clean electrospinning, environmentally friendly electrospinning, green fibers, safe electrospinning, solvents,

1.1 Introduction

Electrospinning is an efficient method that has been recognized for the fabrication of continuous polymer fibers with diameters down to a few nanometers. When the diameter of fibers decreases from micrometer to nanometer, several characteristics show up, such as a large surface area to volume ratio, flexibility, and mechanical performance. Initially, only polymers were accepted as fiber-forming materials. As time went on, ceramics and glasses were also considered as fiber precursors. By virtue of being a very simple and easily controlled technique, the utilization of electrospinning has spread into all fields of work, including biomedicine, pharmaceutics, filtration, energy, sensor, cosmetics, and food packaging.

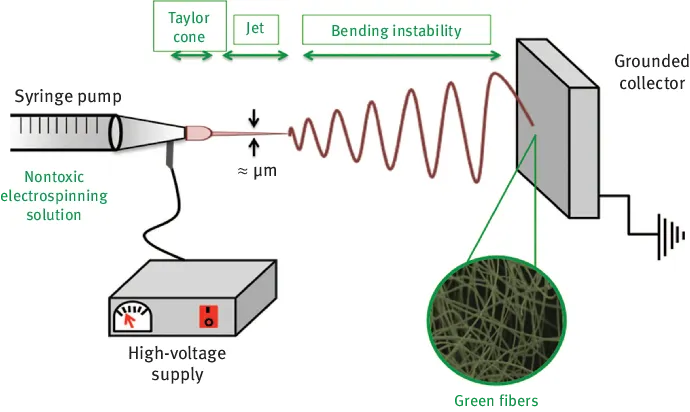

In a typical electrospinning setup, there are three basic components necessary to the process: a high-voltage power supply, a capillary tube with a pipette or needle of small diameter, and a metal collecting screen. During the process, the polymer solution or melt is pumped through the capillary tube and a high voltage is used to create an electrically charged jet of polymer out of the tube. The nozzle of the capillary tube serves as an electrode and a 100–500 kV m−1 electric field is applied. The solvent evaporates and the polymer solidifies while it is transported through the electric field. An interconnected web of fibers is therefore formed on the collecting screen. Considering that the solvent residuals are still present in the resulting nanofibrous mats, they may need to be post-modified to remove or neutralize the undesired solvent traces. The most common solvents for electrospinning are normally toxic organic solvents and, therefore, the presence of solvent residues will limit the use of obtained electrospun mats for any biomedical applications. It could also cause the operator to work under unhealthy conditions. Not only the toxicity of the electrospun scaffolds but also environmental concerns of the evaporating solvent have led to the concept of “Green Electrospinning” as a current issue (Figure 1.1).

Figure 1.1: Schematic representation of green electrospinning setup.

Traditionally, electrospinning has relied heavily on the use of volatile organic solvents (VOCs) [1]. This is because solvents for electrospinning must not only be capable of dissolving the polymer chain but also be capable of evaporating within the short distance that separates the nozzle from the collector. Unfortunately, VOCs can be expensive, toxic, and hard to remove from the environment [2].

The number of journal articles using the term “green electrospinning” has been growing over the last 8 years. Green electrospinning is essentially the same or a similar procedure to traditional electrospinning and follows, therefore, the same overall physical principles that control the fiber diameter. Alterations in the procedure are attempted in order to remove the VOCs from the process and perhaps improve the recyclability and reusability of the various products and starting materials [1].

There are three main hazards in traditional electrospinning that arise due to the use of VOCs:

- There are risks to the product user, particularly in the area of biomedicine, where materials will be implanted along with living tissue and cannot come in contact with toxic solvents.

- Risks to the product producer: many VOCs are quickly brought into the ambient environment around electrospun fibers. If a chamber equipped with vacuum is a part of the electrospinning setup, the solvent exposure is minimized. However, trace amounts left in the porous fiber mats can overtime be dangerous to those working with the mats.

- Risks to the environment: with the clear risk of VOCs and synthetic polymers accumulating within the air, waste that must be handled in particularly ways, with stray fibers that slowly accumulate in the soils (an unfortunate side effect of even washing of synthetic fiber clothes), and VOCs evaporating into the air effect our water, air, and soil quality [3, 4, 5].

Some particularly useful polymers for electrospinning, like polyimides, polyurethanes, and polyamides, require solvents such as dimethylformamide (DMF) or dimethylacetamide to be dissolved, which unfortunately are not volatile [6]. Other common harmful organic solvents may include strong acids such as formic acid, dichloromethane, ether, and chloroform. [7].

Green electrospinning would aim not only to reduce the use of VOCs and other toxic solvents, but to select suitable materials that produce more eco-friendly products. Some more common polymers due to their solubility in more aqueous solutions include polycaprolactone, poly(ethylene oxide) (PEO), and poly(vinyl alcohol), all of which are more easily degraded than polyolefins [1].

1.2 “Greener” electrospinning: on the way to a “truly green” electrospinning

As with many things in life, whether a glass is half empty or half full depends on the perspective of the observer. To consider a certain process “green” or not is one of these cases in which some people see the glass half full and others see the glass half empty. How “green” should an electrospinning process be to be called “green”?

Any person reading this book is certainly aware of the popularity that the adjective “green” has attained in the last few years. The title of the book is the best demonstration. However, in these lines, we have no intention to open sterile controversies, but rather to act somehow as devil’s advocate in our own field and incite in the reader a certain degree of self-criticism when confronted with the so-called – or “self-called” – green strategies. A rapid view of the literature will immediately show us that the concept of green fibers is not univocal and depends very much on the authors. For instance, when the resulting materials are used in biomedical applications, the biocompatibility of the final product is put in the foreground and then the label “green” seems to be almost self-explanatory. But were all chemicals and solvents used during the synthesis of the final biomaterial “truly green”? How green were the processing steps? It is obvious that such a “quantification” is far from trivial. Herein, we would like to point out a few concerns that should be kept in mind, regardless of whether the process is or not called “green”:

- The electrospinning of natural polymers, such as gelatin or chitosan, is commonly considered as “green,” because the products can be considered as such. However, most of the solvents used in these processes are fluorinated (e.g., hexafluoro-2-propanol, tetrafluoroethylene, and trifluoroacetic acid). Similarly, there is a general trend to speak about “green electrospinning” when herbal extracts or essential oils are used in the process, no matter whether synthetic polymers or organic solvents ar...

Table of contents

- Title Page

- Copyright

- Contents

- Preface

- 1 Green electrospinning

- 2 Green processes and green fibers

- 3 Polymer-free electrospinning

- 4 Melt electrospinning

- 5 Supercritical fluid-assisted electrospinning

- 6 Water-based electrospinning

- 7 Natural nanofibers and applications

- 8 Recent advances in the electrospinning of biopolymers

- 9 Needless and syringeless electrospinning for mass production

- 10 A recycling route of plastics via electrospinning: from daily wastes to functional fibers

- 11 Electrospun biocomposite fibers for wound healing applications

- 12 Nanofibers in liquid filtration

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Green Electrospinning by Nesrin Horzum, Mustafa M. Demir, Rafael Muñoz-Espí, Daniel Crespy, Nesrin Horzum,Mustafa M. Demir,Rafael Muñoz-Espí,Daniel Crespy in PDF and/or ePUB format, as well as other popular books in Ciencias físicas & Ciencia medioambiental. We have over one million books available in our catalogue for you to explore.