eBook - ePub

Prioritization of Failure Modes in Manufacturing Processes

A Fuzzy Logic-based Approach

- 200 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Prioritization of Failure Modes in Manufacturing Processes

A Fuzzy Logic-based Approach

About this book

In the contemporary automotive manufacturing industry, service providers are continuously working to improve system optimization in order to remain competitive in the market and deliver quality products to satisfy their customers. With this comes the possibility of failure, rejection and reworking of the components or services in the system, which can incur high costs and impact the reputation of an organization. This book uses Failure Mode and Effect Analysis (FMEA) to assess, investigate and predict the Risk Priority Number (RPN) of potential failures for three companies within the manufacturing industry:

- A metal component supplier in the automotive sector

- Part manufacturer for the automobile and engineering industries

- Manufacturer of suspension components for commercial vehicles

Integrating human expertise and artificial intelligence on a single platform, the authors use fuzzy logic as a tool to overcome the vagueness associated with traditional methods of assessing potential failures. The book also details the procedure and scales of how to conduct FMEA, offering guidance on how to input and rank each risk within manufacturing processes across a range of sectors's. Each of the three real-world cases offer suggested improvements for the companies themselves, alongside takeaways for researchers and professionals within the fields of manufacturing and supply chain management.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Prioritization of Failure Modes in Manufacturing Processes by Jagdeep Singh,Harwinder Singh,Bhupinder Singh in PDF and/or ePUB format, as well as other popular books in Business & Business General. We have over one million books available in our catalogue for you to explore.

Information

Chapter 1

Introduction

1.1 Need for Failure Mode and Effects Analysis – An Overview

In modern automation-based scenarios, all industries or organizations, such as manufacturing and service providers, manufacturing and service providers are working under extreme pressure to continuously improve. They do this in order to remain competitive in the market and delivering quality products to satisfy their customers. Optimization of systems to improve performance is expected in all areas, either from management or from the engineers associated with various processes. The rejection and rework of components or services within the system incurs high costs and brings down the reputation of the organization. Every organization wants to deliver defect-free products to the customer, without any rejection, but in actual practice, this is not the case. Production losses, delays, unplanned intrusions, safety hazards are unavoidable parts of the system. So, failure is something which is associated with the technical system, unavoidable and even sometimes unpredictable.

In case a system suffered from a failure, it made operational or workable after repair or servicing and also prompts to identify the causes of the failures to prevent their occurrence in future. The use of incorrect methods, materials, cutting tools, improper maintenance, inappropriate testing, inadequate inspections, unhealthy environment, poor lightening, excessive work load, and misconduct are few common cause of failures. These factors may result in loss of time, loss of material, loss of equipment and tools, and sometimes even in human life.

Such undesirable consequences, due to unacceptable and unreliable behavior, lead to improvements in system performance. The enhanced performance of the system leads to improved productivity, increased product reliability, higher quality products, and improved organizational reputation. The same can be achieved by adopting an optimized design during the initial stages and maintaining the same during the production and service of the product. The reduced cost of product with improved quality ensures the trust of customer and leads to continual improvement.

The meaning of failure is the incapability of a framework or item to perform the desired function and inability to fulfil the mandatory requirements. Failure might be emotional, abrupt or unpretentious and concerned about the framework or item which is ruined. The faulty products affect the wider society, society as they include common home appliances or costly automobiles. It can also include the services of bank or telephone companies, sometimes causing a shortage of products or a breakdown in services. If a patient is diagnosed incorrectly due to poor services at a hospital, this would harm the reputation of the hospital, and is another example of failure.

Nowadays, with new technological developments, the problems are becoming more complex and have become more difficult to correct. The process of making or predicting a failure-free processes is becoming critical. Some decisions might be best recommended but sometimes fail as well making this job critical for the managers or engineers. Maintenance plans must involve both technical, as well as the management strategies, to address the criticality involved in the system. Every component must be assessed to identify potential failures and giving their best solutions within the constraints of failure type, pattern of failure, impact of failure, and cost incurred in failure, all while implementing the solution while implementing the solution.

Such information is utilized by various department personnel to choose appropriate action to prioritize different processes. All tangible and intangible attributes considered signify the intricacy of the problem and, in order to improve the consistency of system, various failures must be prioritized based on their modes of failure. Ranging from high priority to low priority, criticality is decided, and maintenance policy can be framed depending upon the different priorities. Some failures need corrective action, whilst others need preventive maintenance schedules and regular or conditional monitoring to evade failures and augment the system consistency. Generally, risk priority number (RPN) is calculated using failure mode and effects analysis (FMEA) to prioritize the potential failure modes.

Optimization of systems to improve performance is expected in all areas, from the managers to the engineers associated with various processes. The rejection and rework of the components or services in the system incur high costs and bring down the reputation of the organization. In the modern automation-based scenario, all industries or organizations, such as manufacturing and service providers, are working under extreme pressure to improve themselves continuously to remain competitive in the market and deliver quality products to satisfy their customers. Every organization wants to deliver defect-free products to the customer without any rejection, but in practice, this is not the case. Production losses, delays, unplanned intrusions, and safety hazards are unavoidable parts of the system. Therefore, failure is something which is associated with the technical system, unavoidable, and even sometimes unpredictable. Nowadays, the problems are becoming more complex and often it is difficult to find corrective measures. The process of making or predicting failure-free systems is becoming critical for managers and engineers. Maintenance planning must involve both technical and management strategies, to address the criticality involved in the system. Every component must be assessed to identify potential failures and giving their best solutions within the constraints of failure type, pattern of failure, impact of failure, and cost incurred in failure. The tangible and intangible attributes considered, signifies the intricacy or criticality of the problem. And to improve the consistency of system, it is required that various failures must be prioritized considering the criticality of their modes of failure. Further ranging from higher to lower priority, criticality is decided, and maintenance policy can be framed depending upon the different priority. Some failures need corrective action while other needs the preventive maintenance schedule and regular or conditional monitoring to evade failures and augment the system consistency.

1.2 Traditional FMEA

The failure mode and effect analysis (FMEA) used to identify and manage the risk involved, is an organized and multidisciplinary team-based approach which helps to enhance reliability of system and ensures the safety in design or process used in any industries. FMEA is utilized to classify and abolish the potential failures present in a design or process, by computing the risk priority number based on methodology of multiplication of severity, occurrence, and detection. FMEA is a multicriteria decision-making approach, to augment the capability of identifying the risk and potential failures. FMEA is a robust methodology used to identify, classify, and analyze potential risk in process. FMEA approach comes up with potential failure modes at first and recognizes the impact on the following sublevel in machine-driven organizations.

Grumman Aircraft Corporation in the 1950 and 1960s developed the formal FMEA methodology and applied it to the flight control systems of naval aircrafts. Since then, it has been used extensively by aerospace, nuclear, and automotive industries to analyze their products for safety and reliability in processes. Ford Motor Company adopted FMEA in 1977 and extended the procedure to assess and prioritize the potential failures while designing automotive components and process involved in manufacturing.

FMEA methodology is a valuable tool at the hands of persons responsible for organizing the production, in terms of reliability and quality management of products and processes. It is an inseparable part of risk management and it supports continuous improvement. The main aim of the method consists of detecting the effects and causes of failure modes that can affect the reliability, the quality, and not least the safety of products, whether it is product, process, system, or service analysis.

FMEA involves teamwork, management support, and deep knowledge of systems, products, processes, time, and cost. Therefore, to be successful, this technique should be fully implemented quality management system both within the product development and processes. This will enable companies to rationalize their activities and thus reduce costs and increase efficiency.

A failure mode and effects analysis (FMEA) is a methodology in product development and operations management for analysis of potential failure modes within a system for classification by the severity and likelihood of the failures. A successful FMEA activity helps a team to identify potential failure modes, based on past experience with similar products or processes. Failure modes are any errors or defects in a process, design, or item, especially those that affect the customer, and can be potential or actual. Effects analysis refers to studying the consequences of those failures. An example of this is the Apollo Space program. It was also used as application for Hazard Analysis Critical Control Point (HACCP) for the Apollo Space Program, and later the food industry in general. The primary push came during the 1960s, while developing the means to put a man on the Moon and return him safely to the Earth. In the late 1970s the Ford Motor Company introduced FMEA to the automotive industry for safety and regulatory consideration after the Pinto affair. They applied the same approach to processes (PFMEA) to consider potential process induced failures prior to launching production.

As FMEA is used as a risk assessment tool to improve quality of product in manufacturing industries, it involves the use of the human knowledge and expertise to predict the potential risk or failure modes involved in the process. The evaluation of such potential failure parameters of a process helps the FMEA team to suggest curative arrangements or initiate precautionary actions at the earliest opportunity to eradicate or lessen the opportunity of the failures. Further it can be added that FMEA is a structured tool to identify:

- the possible failure modes,

- the properties of the probable failures, and

- the seriousness of failure impacting the process.

FMEA technique includes the utilization of three strictures – severity, occurrence, and detection – to portray every failure involved in a process or product. Severity is the significance of the disappointment. Occurrence is the rate of the disappointment happening. Detection is the probability of detecting the disappointment. Here disappointment represents failure. Individual constraint has been rated on a scale of 1 to 10. Using the methodology of multiplication, the product of severity, occurrence, and detection gives the RPN, which generates the criticality of each failure, giving high priority to large-valued RPN. The potential failure with high RPN needs to be addressed immediately.

1.3 Development of FMEA

Table 1.1 shows the various phases of development of the FMEA over the years.

Table 1.1.Over the Year's Development of the FMEA.

| Year | Description |

|---|---|

| 1963 | FMEA was first proposed by aerospace industry |

| 1965 | The military of the US started to apply the FMEA technique |

| 1974 | The military of the US published the SOP of FMEA: MIL-STD-1629 |

| 1977 | Ford Motor started to use FMEA |

| 1980 | The revised SOP of FMEA: MIL-STD-1629A |

| 1985 | The International Electro-Technical Commission (IEC) published SOP of FMEA: IEC 812 |

| 1993 | Ford, Chrysler, and General Motor established the 1st edition FMEA reference manual |

| 1995 | The 2nd edition of FMEA reference manual was revised by AIAG |

| 2001 | The 3rd edition FMEA reference manual was revised by AIAG |

| 2008 | The 4th edition FMEA reference manual was revised by AIAG |

| 2008–now | FMEA is considered as an important analytical method by ISO-9000, ISO/TS 16949, and it has been widely used in risk assessment and quality improvement |

1.4 FMEA Objectives

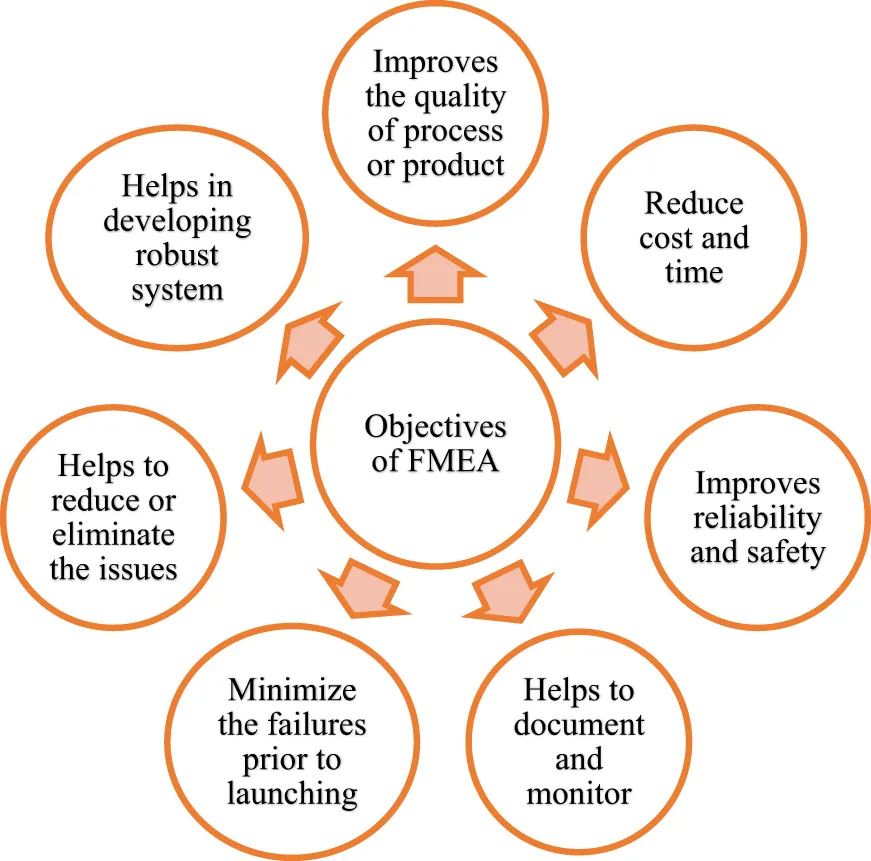

FMEA becomes very popular and common in the industries as it fulfills or promises the following objectives as mentioned in Fig. 1.1.

Fig. 1.1. Various Objectives of FMEA.

1.5 Classification of FMEA

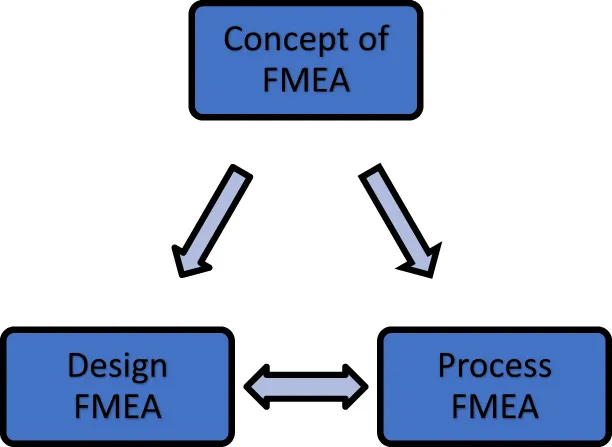

Initially the life of any product begins with the identification of need followed by planning the concept. The next phase is design and development, followed by the production or manufacturing of the product. Once the component is sold, it involves the maintenance and repair and ends with the disposal of the product. All stages involve some challenges and potential risks, but FMEA procedure is adopted in the product design or manufacturing processes. Therefore, depending upon diverse purposes while concentrating process or design involved, the classification of FMEA has been shown in Fig. 1.2 and discussed further.

Fig. 1.2. Types of FMEA.

1.5.1 Design FMEA

Design FMEA is applied at the design stage of the product. It is utilized to break down items before they are sent for proce...

Table of contents

- Cover

- Title

- Copyright

- Table of Contents

- Acknowledgment

- Chapter 1 Introduction

- Chapter 2 Traditional FMEA – Application

- Chapter 3 Fuzzy-based FMEA – Application

- Chapter 4 Fuzzy FMEA and Fault Tree Analysis – Application

- Chapter 5 Line Balancing Problem – Fuzzy-based Application

- Chapter 6 Conclusions

- Appendices

- Index