- 416 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

This revised 3rd edition details the factors involved in the injection moulding process, from material properties and selection to troubleshooting faults, and includes the equipment types currently in use and machine settings for different types of plastics. Since material flow is critical in moulding, the book covers rheology and viscosity. High temperature is also discussed as it can lead to poor quality mouldings due to material degradation.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1 Introduction

1.1 The big picture

When the Hyatt brothers, John and Isaiah, built and patented the first injection moulding machine (IJM) in 1872, it is doubtful they could possibly have imagined the impact this invention would have on the world. It spawned a worldwide industry employing millions of people.

In 2013, plastic manufacturers generated over 373 billion US dollars (USD) in the US alone with the plastic industry employing 900,000 people there. The worldwide consumption of plastic materials rose from 245 million metric tonnes in 2008, to 311 million metric tonnes in 2014. China uses over a quarter of the world’s plastics, with this figure increasing year on year as manufacturing grows. Europe’s manufacturing base is the second largest global market consuming around 20%. The Chinese market is increasingly prominent across the entire plastics sector and China is currently both the largest producer of machines in the world and the biggest consumer of them, which drives the need for a plastic raw materials market as well.

IJM sales in China had reached a market worth 25.5 billion Chinese yuan [renminbi (RMB)] in 2013, and was expected to reach RMB30 billion by 2016.

The packaging sector accounts for the majority of the world market, with the automotive industry and the electrical equipment industry also both heavy consumers of plastic and injection mouldings. Other important markets for plastic materials are the construction industry and consumer products.

A major factor for the entire injection moulding industry (and manufacturing in general) has been the globalisation of the market. Like other industries, successful IJM manufacturers have kept pace with changes in global demand and moved to lower cost production plants in the world’s developing economies, such as China, India and Brazil. To adapt to the increased competition, the successful manufacturers are the ones that have been able to adapt, innovate and compete.

From these few facts and figures it can be seen that injection moulding is an extremely large and important manufacturing industry, but what is injection moulding?

1.2 Introduction to injection moulding

Injection moulding is one of the most commonly employed processes to produce plastic parts. It is a cyclic process of rapid mould filling followed by cooling and ejection. A variety of materials both plastic and non-plastic can be used as feedstock; however, the machine must be configured for the type of material used.

The material, which is generally available as grains or powder, is plasticised in an injection unit and injected into a clamped mould under high pressure (500–1,500 bar). The main advantage of injection moulding is it is a very economical method of mass production. Ready parts with tight tolerances can be produced in one step, often completely automatically and, in general, subsequent processing steps are not necessary. It is also possible to integrate different functions into one part to avoid the formation of different components that would be more expensive, and some of these more advanced and integrated processes are discussed in Chapter 10.

To guarantee a high-quality injection moulded part the following points have to be considered:

- The material has to be plasticised and injected carefully to avoid negative effects on the properties and characteristics of the material.

- The process settings (such as pressures and temperatures) concerning the machine and mould have to remain constant with regard to time and space.

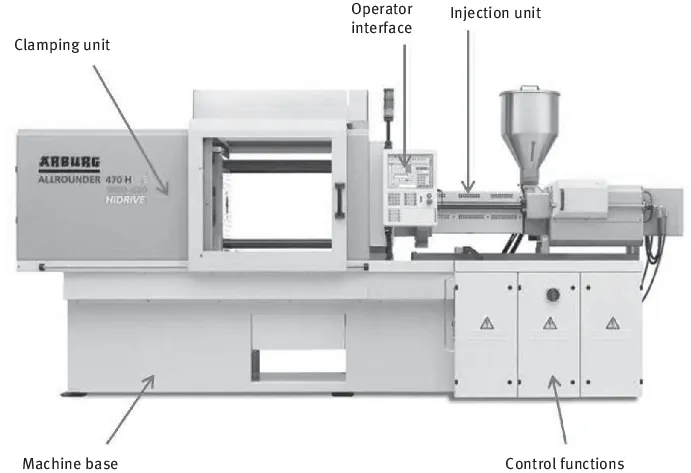

An example of a commercially available IJM is shown in Figure 1.1 and the basic parts that make up a machine are shown in Figure 1.2.

Figure 1.1: An injection moulding machine (IJM).

Figure 1.2: Basic components of an IJM.

The computer control unit allows the machine operator to control and monitor the process; control systems will be discussed in Chapter 5.

The purpose of the injection unit is to melt and meter the material into the tool; machinery will be discussed in Chapter 3.

The clamp unit holds the injection moulding tool and gives the required clamp force to hold the two sides of the mould tool together; tooling will be discussed in Chapter 4.

The machine base is powered by either electrical or hydraulic means, and houses the systems that drive the movement of the machine. Each machine has a certain ‘footprint’, which is the floor space it requires for operation.

1.3 The injection moulding process

During the injection moulding process, the mould and the plasticising area are separated from each other. The temperature of the plasticising area, i.e., the plasticising cylinder, is maintained at the same level as the processing temperature. The mould on the other hand, is kept cold enough for demoulding of the injection moulded part (thermoplastics), or warm enough for crosslinking (thermosets). The plasticised material is injected into the clamped mould. In an IJM, the clamping unit, which contains the mould and injection unit, is integrated. Completely automated production is possible if the mould is installed with a vertical parting line, which enables the parts to fall down and out of the mould after demoulding. IJM are more typically used for the processing of thermoplastics. There are two types of injection unit available: a piston injection unit and a screw piston injection unit (reciprocating); the reciprocating screw method is the most common. Only screw piston machines can be used for the processing of thermosets as without the screw, the dwell time would be too long and the risk of early crosslinking would be too high. The injection sequence for both types of machine now follows.

1.3.1 Piston injection unit

Injection sequence:

- Injection starts (clamped mo...

Table of contents

- Title Page

- Copyright

- Contents

- Preface

- 1 Introduction

- 2 Introduction to plastics

- 3 Injection moulding machinery

- 4 Injection mould tooling basics

- 5 Process control systems

- 6 Amorphous and semi-crystalline thermoplastics

- 7 Processing thermoset, liquid silicone rubber and ceramic materials

- 8 Guide values and processing instructions for the most important thermoplastic injection moulding compounds

- 9 Practical applications using injection moulding technology

- 10 Advanced processing techniques

- Abbreviations

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Injection Moulding by Vannessa Goodship in PDF and/or ePUB format, as well as other popular books in Physical Sciences & Chemistry. We have over one million books available in our catalogue for you to explore.