- 278 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

This popular science title covers adhesion science in an easily accessible entertaining manner. As well as outlining types of adhesion and their importance in everyday life, the book covers interesting future applications of adhesion and inspiration taken from nature. Ideal for students and the scientifically minded reader this book provides a fascinating introduction to the science of what makes things stick.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Sticking Together by Steven Abbott in PDF and/or ePUB format, as well as other popular books in Physical Sciences & Industrial & Technical Chemistry. We have over one million books available in our catalogue for you to explore.

Information

CHAPTER 1

Introduction

Modern society would fall apart without adhesives.

Your smartphone has at least 25 adhesive joints in it, with the all-important glass screen and the display held with adhesives, as are the chips, microphones, speakers and aerials inside. The screen protector is also stuck on.

Now step into your car. Manufacturers are under intense pressure to reduce weight. Every screw or rivet is a potentially avoidable weight (yes, automobile manufacturers agonize over each gram in each component) and the interior of a modern car is held together by clips (for removable parts) and adhesives. External parts such as bumpers (fenders) used to be metal. Now they are made of polypropylene, strongly adhered to the metal shell. Even the metal shell itself is rapidly heading for history as plastic/carbon fibre takes over, held together with adhesives.

What about something really important such as an aircraft? The interiors are stuck together – the weight, inconvenience and aesthetics of screws and rivets make them unacceptable. The rivets we see on the outside give the impression that they are the key structural element, yet they are now mostly for backup or are redundant. Even the (by now) old all-metal aircraft are largely held together with adhesives, while the latest generation of civil aircraft such as the lightweight, efficient Boeing Dreamliner and Airbus 350 are predominantly glued together.

And yet, the hidden nature of adhesives (if you can see them, they probably haven't been applied properly), allied with their avoidability (people often prefer to try other methods first), has led to a rather dismissive attitude to the whole technology. When I mention my interest in adhesives to friends and neighbours, the general response is that adhesives are trivial, unsatisfactory or excessive, i.e. they are only an occasional feature of their lives, they often don't work well and can be (like my wife's orchid jug mentioned in the Preface) unsightly when used; as such they are not of any great importance. There is a medieval notion that to “really” put things together you need nails, screws, rivets and welding.

Talk to anyone who really needs to put things together and you find a horror of nails, screws, rivets and, with the exception of steel for which it is wonderful, welding. A good way to make anything fail is to put a hole in it or to heat parts of it while other parts remain cool. When things are held together by nails, screws or rivets, stresses are focussed on the hole and crack cans start there. Those fixing devices become instant sources of potential failure. The bio-inspired hook-and-loop type of fasteners developed and commercialized under the name Velcro are an ingenious variant on the old hook-and-eye system. Although they are a welcome addition to the world of fasteners thanks to their ability to distribute a load over a wide area, because they are purely mechanical, they feature no further in this book. And, of course, these fasteners themselves are often attached via a strong adhesive.

Adhesives, in contrast to conventional fixings, spread the load and do not require you to add defects to your object. This means that they are used just about everywhere.

The high-tech adhesives industry is very much alive and well. For phones, cars, aircraft, medical devices, construction, packaging – just about everywhere – customers demand not so much better adhesives as better adhesive systems that deliver a package of benefits.

As we will discuss later, there is a constant set of trade-offs to be battled. Prioritizing strength and hardness can lead to systems that are too brittle and cannot cope with shocks. Making things flexible and resilient can lead to compromises in resistance to those steady, long-term forces that can produce creep (slow deformation) within the bond.

Providing controlled low adhesion is especially tricky for consumers.

- People like easy-open packages and get frustrated if they are too hard to pull or give a raspy “stick-slip” release. But no one likes it when they are so easy to open that this has happened during storage.

- Similarly, we all want hooks that are easy to stick to a surface and that securely support a large weight. But we also want them easily removed and repositioned with zero damage to the surface.

In addition to the functional challenges, everyone says that they want “green” adhesives. Going back to the bad old days of collagens and milk protein, which will be discussed in Chapter 1, is not a sensible option, both technologically and in terms of those who would object to animal products in, say, their smartphone. Trying to replace petroleum-based adhesive ingredients with those made from renewable resources is neither straightforward nor provably green. A life cycle analysis that takes into account, for example, the water and fertilizer used in growing a crop, the energy needed to harvest it and transport it, plus all the processing and waste disposal does not automatically show that such materials are preferable. And that is before taking into account the alternative use of that land: growing crops for food. This is not just my personal view; some major EU studies on, for example, bio-based plastics confirm that there are often major downsides to switching from petrochemical alternatives. I have had conversations with urethane manufacturers who are frustrated by the fact that the variability of bio-based raw materials has a serious impact on performance, with whole batches sent to waste (definitely not green) because the adhesive performance was sub-standard.

In the foreseeable future the greenness of the adhesives will consist of doing more with less; minimizing the amount of adhesive in each bond, which in turn requires greater precision in the parts to be adhered. You can't use a 1 µm layer of adhesive if the parts have a 5 µm roughness. And as more and more parts of products such as cars and aircraft are made from (fibre-reinforced) plastics, the environmental upsides from using a small amount of a high-performance “non-green” adhesive far outweigh any environmental downsides of the adhesive itself.

Nature has many examples of ingenious modes of adhesion that excite a lot of well-intentioned publicity when scientists find ways to use similar principles. As we shall see in the final chapter, the principles are usually more to be admired than to be copied. If I am flying in an aircraft mostly held together by adhesive, I far prefer a wholly synthetic, high-tech, apply-and-forget adhesive to a “smart” bio-inspired one that needs a constant supply of chemicals in water to keep it in good shape.

1.1 WHICH ADHESIVE SHOULD I USE?

What everyone, manufacturer or user, wants to know is whether this specific adhesive will do a great job on this specific adhesive problem. We have the whole of Chapter 3 to see how adhesion is tested in the lab. What about testing it at home?

Mostly we have one-off jobs such as sticking a drawer handle back on, or fixing the leg of a chair. Our “test” therefore is whether the job worked out OK.

If we regularly do an adhesion task then we can try out a few different adhesives and a few different application methods, working out which is the best balance of cost, speed and effectiveness. Most of the time we don't have that luxury – we have to make a one-off decision to use this adhesive, applied in this manner to stick these things together. If it works, no one will ever comment. If it fails, then you risk anything from embarrassment to significant loss.

One aim of this book is to help you make the right choice of adhesive for any given job, and in Chapter 6 we review many common systems for sticking A to B. To make the right choice you need a key fact that is missing from most accounts of adhesion and adhesives. Here it is:

“Adhesion is a Property of the System”.

You will have no problem remembering this phrase because, I make no apology, it appears many times throughout the book.

The biggest mistake any of us can make when thinking about an adhesion problem is to focus on the adhesive, rather than the system. If your system is going to involve lots of peel, then, as we shall see, don't bother with a superglue. If your system involves lots of shear, then (all this will be explained clearly later) the strength of the bond depends as much on the thickness and modulus of the adherends (the things you are adhering) as on the adhesive. If you can increase the thickness and/or modulus of the adherends you are already improving things, even without thinking about the adhesive.

Then you need to worry about speed, and its equivalent, temperature (yes, the two are strongly inter-related as we shall discover). If your problem is long, slow loads and/or higher temperatures then a “strong” adhesive will be right. If the problem involves short, sharp shocks (and/or cold temperatures) then a strong adhesive might be catastrophically brittle and you will need something far more forgiving. The common PVA wood glues are used extensively not because they are amazingly strong (which they're not) but because they are amazingly forgiving when the woods in the joints (they might be different types of wood or in different grain directions) expand or shrink with the rise and fall of humidity.

Adhesives have, as we will see, moduli, viscosities, glass transition temperatures, curing speeds, degrees of cure, crosslink densities. Each of these can be measured and a supplier could, if necessary, give you all those values. What no supplier can give you is a meaningful statement about how strong it is, because no adhesive has “a” strength, because Adhesion is a Property of the System.

A supplier can say that this adhesive can survive X N m−2 when tested against Test Standard XY92, and you can compare that to a different adhesive tested against the same standard and it is possible that the test is relevant to the type of loads you are trying to resist. But we are not likely to have such a situation in our day-to-day fixing jobs.

I now want to flip all these negatives into a positive. You are the one who knows what you are sticking to what, for what reasons, and you know the sorts of assaults the joint will receive over its required lifetime. You also know the restrictions of contamination, access space, time, temperature, weather, sunlight. You are the world expert on your system. Now that you know that Adhesion is a Property of the System, and that you are the expert on that system, you don't have to be taken in by adverts for glues that work only under the precise conditions created for the advert. You don't have to be fooled by statements like “sticks anything to anything”, with a little asterisk pointing you to a set of disclaimers in small print.

With help from the chapters that follow, you will be able to:

- Understand what will or won't help with surface preparation

- Look at advertising claims with a healthy scepticism

- Choose between a “strong” or a “tough” adhesive

- Choose between a thick or thin layer of adhesive

- Choose between a good general-purpose adhesive and one (allegedly) specifically designed for your sort of system

- Know whether the adhesion promoters present in some adhesives will help (and how) or hinder (and why)

- Understand why too much of a good thing is a bad thing

- Find out how to reduce adhesion when you need to

You cannot do these things well if you assume that everything is down to the adhesive. By understanding the system, you go a long way towards understanding how to get the best out of what you have to hand.

1.2 HOW THE BOOK UNFOLDS

We start by admiring those pioneers of adhesion who managed to take crude raw materials such as birch bark tar or boiled bones to create really rather impressive adhesives. We then switch to some necessary basics to become familiar with the few core ideas needed to understand the rest of the book. By looking at how geckos manage to stick to walls, we see the sort of adhesion we mostly don't want, getting ready to find out how to get the (usually) strong adhesion we do want. But before getting to strong adhesion we need to know how to measure if our adhesion is strong. Because adhesion is a property of the system, this is by no means obvious. Then we can get to understand how strong adhesives work (and when they will fail). Because much of strong adhesion depends on strong polymers, we need then to switch to pressure sensitive adhesives (common tapes) that give strong adhesion thanks to very weak polymers. What unites the strengths of both types of adhesives is that they each manage to dissipate the energy of a potential crack; adhesion is much more about dissipation than it is about “strength”. That completes the next five chapters and provides all the principles we need. The final five chapters are about specific systems and how they work with the principles we've worked hard to understand.

CHAPTER 2

Background Ideas

We take adhesion for granted because most of the time it just works. We only notice it when it goes wrong – when the thing we fixed at home breaks again or when the removable adhesive isn't so easy to remove. One reason for us taking adhesion for granted is that modern adhesives are so good. It wasn't always like that.

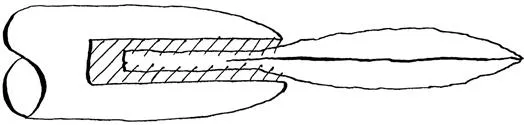

Take yourself back hundreds of thousands of years. Adhesion is now a matter of life or death. If you can reliably stick a flint arrowhead into a slot at the front of an arrow (and stick some feathers onto the back) then you will be able to eat tonight (Figure 2.1) – if not you starve. How hard can it be? Just get some sticky stuff and, well, stick it. Ah, that pine tree has some sticky stuff, let's try it. The real sticky stuff is too soft, so you try the hardened version, using a fire to melt it. Pour it around the arrowhead and stick and, when it has cooled take a test shot. As soon as the head touches the target, the brittle pine glue shatters. You won't eat tonight. After a few decades or centuries, chance or a course in advanced nanotechnology leads someone to mix the pine resin with the right sort of finely-ground charcoal. Now the adhesive is shatter-proof.

Figure 2.1 Gluing a flint arrowhead into a wooden haft is a big technical challenge. It is impressive that Neanderthals managed to do it with birch bark tar that was neither too soft nor too brittle.

This story of the development of a working adhesive captures the frustrations of adhesive developers today. It is easy to make an adhesive that is too soft, it is easy to make one that is too hard and brittle. Finding the right balance remains a deep challenge, especially because, as emphasized in this book, adhesion is a property of the system, not just of the adhesive.

There has never been a shortage of things that might produce a useful glue. Anyone who has overcooked any starchy food has created an adhesive. You don't even have to cook it – a paste of wheat or corn starch creates an equivalent glue. It just isn't very good, especially if the joint ever gets wet. Bacteria and moulds love to feast off the nutrients, so a starch-based glue will go off in storage and a joint might fail via mould growth.

Birch bark tar (pitch) has been a wonderful adhesive for thousand...

Table of contents

- Cover

- Title

- Copyright

- Preface

- Contents

- Glossary

- Chapter 1 Introduction

- Chapter 2 Background Ideas

- Chapter 3 Sticking Like a Gecko

- Chapter 4 How Stuck Is Stuck?

- Chapter 5 Strong Adhesion

- Chapter 6 Strong Adhesion with Weak Polymers

- Chapter 7 Sticking Other Things Together

- Chapter 8 Watching Paint Dry

- Chapter 9 Sticking in 3D

- Chapter 10 Not Sticking

- Chapter 11 How Nature Sticks Things

- Subject Index