eBook - ePub

Alloy Materials and Their Allied Applications

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Alloy Materials and Their Allied Applications

About this book

Alloy Materials and Their Allied Applications provides an in-depth overview of alloy materials and applications. The 11 chapters focus on the fabrication methods and design of corrosion-resistant, magnetic, biodegradable, and shape memory alloys. The industrial applications in the allied areas, such as biomedical, dental implants, abrasive finishing, surface treatments, photocatalysis, water treatment, and batteries, are discussed in detail. This book will help readers solve fundamental and applied problems faced in the field of allied alloys applications.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Alloy Materials and Their Allied Applications by Rajender Boddula, Mohd Imran Ahamed, Abdullah M. Asiri, Rajender Boddula,Mohd Imran Ahamed,Abdullah M. Asiri in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Materials Science. We have over one million books available in our catalogue for you to explore.

Information

1

Fabrication Methods for Bulk Amorphous Alloys

Marcin Nabiałek

Institute of Physics, Faculty of Production Engineering and Materials Technology, Czestochowa University of Technology, Częstochowa, Poland

Abstract

Amorphous alloys are one of the newer groups of functional materials that are widely used in many industries. Their properties are much better than materials with the same chemical composition and crystal structure. Amorphous alloys are produced by rapid cooling techniques. The most popular methods are: melt-spinning method, injection method, suction method, centrifugal method. Using these methods, products of various shapes can be produced. There are two groups of amorphous materials: conventional in the form of a thin tape and bulk amorphous materials with a thickness of more than 100 µm and various shapes, e.g. rods, tubes, plates, etc. The era of bulk amorphous material began when A. Inoue of Tohoku University in Japan developed three criteria. These criteria make it possible to systematically manufacture massive amorphous materials. Of course, there are many restrictions on their production, but the date 1989 is the date of birth of a new group of materials, i.e. bulk amorphous alloys. Material engineers need such materials and their development is continuous, as evidenced by numerous scientific publications in this field. It should be assumed that the growing demands on modern materials will promote the development of this group of materials.

Keywords: Bulk amorphous materials, injection casing, suction casting, application of amorphous materials

1.1 Production Methods of Amorphous Materials

1.1.1 Initial Preparation for the Production of Amorphous Materials

Initial preparation of the specific chemical composition of the alloying components—prior to the main melting process—is a fundamental operation in the production process of amorphous materials. The results of many years of the Author’s own research corroborate the fact that the initial ingot preparation, or even the material used to make the ingots in the first place, defines the quality of the amorphous materials. The most important criterion for success is to determine the correct weights of the alloying elements for the ingot. For example, in the case of rare-earth metal elements, the redundant mass of these elements has to be taken into account. The weight of the other alloying elements should be determined to an accuracy of ±0,001 g. For the initial ingot preparation, high-purity elements should be used, as this gives a higher probability that the resultant alloy will have an amorphous structure. However, this increases the production cost of this type of material. Therefore, alloying elements with a purity of 99.99% are used only for the first test samples.

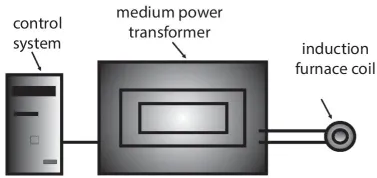

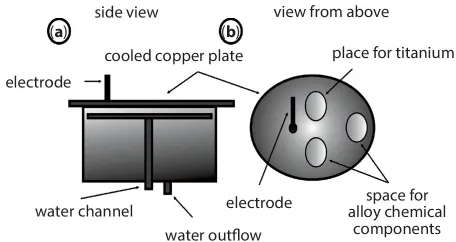

Generally, two alternative methods are utilized for the production of the ingots: using an induction furnace (Figure 1.1) or by arc-melting (Figure 1.2). The production process of a polycrystalline ingot, using an induction furnace, is a very long and labor-intensive process. The alloying components are usually placed in quartz capsules and re-melted several times using the induction (eddy-current) heating process. Each subsequent re-melting of the components results in improved homogeneity of the final ingot. However, this method struggles when it comes to some of the “hard to melt” metals. The presence of non-melted alloying components can be observed by various microscopy methods. In the case of the second ingot production method, using a plasma arc, a much higher degree of mixing of the elements in the alloy can be obtained, than by using the induction method. The temperature of the electric arc depends on the current and can reach up to several thousand Kelvin. The ingot material is melted on one side; then, after allowing a few seconds for solidification to occur, it is turned over using a manipulator and melted again. The production of the ingot, using the arc-melting method, is a single-step process—which reduces the cost and time of the production process, in comparison to the induction method.

Figure 1.1 Schematic view of the induction method for the production of crystalline ingots.

Figure 1.2 Schematic views of the arc-melting method for the production of crystalline ingots: (a) side view, (b) plan view.

Figure 1.3 The surface of a crystalline ingot—arc-melting method: (a) after cleaning and (b) before cleaning.

The initial preparation of ingots that are made from metallic materials is carried out in a vacuum, or under the protective atmosphere of a neutral gas (usually argon). This measure prevents the creation of oxides on the metal surfaces—heterogeneous “embryos”, which could become centers for crystallization, later in the production process.

The manufactured ingots are cleaned by abrasion and by an ultrasonic cleaner (Figure 1.3).

1.1.2 The Single-Wheel Melt-Spinning Method

The unidirectional cooling of liquid alloy at high speed on a rotating copper cylinder was one of the first methods used for the production of solid, metallic amorphous materials in the form of tapes (ribbons) [1, 2]. By the 1970s, this method had been used on an industrial scale for the production of materials for the electrical and electronic industries by the companies Metglas and Vacuumschmelze [3, 4]. The production process involves forcing the liquid...

Table of contents

- Cover

- Table of Contents

- Preface

- 1 Fabrication Methods for Bulk Amorphous Alloys

- 2 Designing Corrosion-Resistant Alloys

- 3 Ni-Co-W Alloys: Influence of Operational Process Conditions on Their Electroplating

- 4 Synthesis and Characterization of Al-Mg-Ti-B Alloy

- 5 Magnetic Alloy Materials, Properties and Applications

- 6 Microstructural Characterization of Ball Milled Co60Fe18Ti18Nb4 Alloys and Their Photocatalytic Performance

- 7 A Narrative Insight on the Biocompatibility Issues for Dental Alloys and Other Materials

- 8 Technological Advances in Magnetic Abrasive Finishing for Surface Treatment of Alloys and Ceramics

- 9 Alloy Materials for Biomedical Applications

- 10 Alloys for K-Ion Batteries

- 11 Shape Memory Alloys

- Index

- End User License Agreement