![]()

1

Introduction

This chapter presents an outline of the book with a series of definitions to delineate clearly exactly what is meant by the term ‘feedpad’ and other farm facilities associated with the feedpad operation.

The main points in this chapter:

• This book presents a detailed overview on dairy feedpads, their planning and construction to their day-to-day management, from the perspective of the farmer. It is not a technical manual on how to design and build a feedpad.

• The basic components of any feedpad system can be likened to different rooms in a house, each one purpose-built and requiring specific planning, designing and over time, maintenance.

• Research and development into dairy feedpads has been conducted in Australia for over 25 years, but farmer interest has been increasing only over the last decade. In 2008 nearly 300 farmers in northern Victoria sought advice from the Victorian Department of Primary Industries’ (DPIV) Dairy Farm Services.

• The DPIV has conducted dairy research and extension programs on feedpad development and management since the early 1980s.

• Before discussing feedpad designs in detail, this chapter defines exactly what the terms ‘feedpad’ and ‘feedlot’ mean and what are the differences between loafing, wintering, stand off and calving pads.

This book presents a detailed overview of dairy feedpads, from their planning to their construction to their day-to-day management, primarily from the perspective of the farmer. In recent years, much has been written on dairy feedpads, but this has been mainly from the viewpoints of effluent specialists, civil engineers, academics and building contractors. This is not unexpected given the dramatic increases in environmental concerns and accountabilities of livestock farmers regarding how they use their farm resources to make a living.

When farmers are contemplating building a feedpad from scratch (on what is called a ‘greenfield’ site), or upgrading an existing cow-feeding facility, naturally one expects that they would seek professional advice from a wide range of service providers. These would include:

• builders of such stock handling and management systems;

• local and state government agencies regarding existing legislation or if none is available, relevant guidelines for their construction and operation;

• suppliers of associated machinery (such as effluent pumps or mixer wagons);

• suppliers of supplementary feeds to overcome future anticipated pasture limitations;

• dairy advisers and consultants (and maybe veterinarians) to help develop the recommended management plans, feed budgets and, if necessary, environmental risk assessments;

• design engineers and concrete specialists to provide detailed drawings and building plans;

• financial advisers to assist with planning and implementing a business plan for financing its construction and day-to-day running costs; and

• dairy farmers who have developed successfully operating feedpads for their grazing cows and other dairy stock.

These service providers are likely to be specialists in their particular fields, able to provide the types of specific information required at each stage of feedpad development and operation.

Why write this manual?

Unfortunately not all farmers follow this logic of seeking out information relevant to their needs. They may simply depend on opinions from their fellow farmers who may, or may not, have had experience with these kinds of feeding and management systems. As well as providing a detailed overview of the topic, this book will complement feedback from other farmers about their experiences of intensifying their pasture-based dairy production systems through incorporating a centralised supplementary feeding station on their farm. Associated with the actual feeding is the provision of water, space, protection from climatic extremes and the removal of effluent and other feedpad wastes. This book also provides direction for farmers seeking specialist details for specific issues of feedpad construction and management.

Feedpads provide an easily visual example of intensification of farming practices that are often considered controversial by community lobby groups such as those representing animal rights and environmental issues. To be comprehensive, this book then covers animal welfare as it affects cow well-being, behaviour and health, as well as effluent management and reuse.

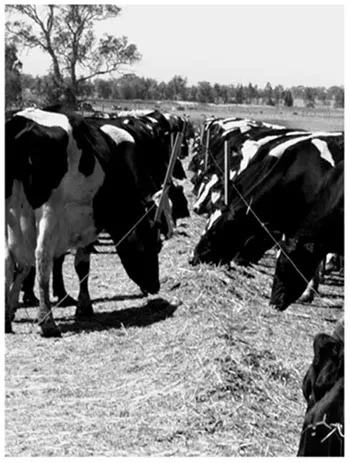

Figure 1.1 Feedpads can be simple or complex, depending on their purpose.

The book does not aim to be a technical manual on how to design and build a feedpad. It does, however, contain relevant summaries from two of the key published guidelines for feedpad construction, namely those developed by the Goulburn Broken Catchment authorities in northern Victoria (SIRIC 2002) and the recently published Guidelines for Victorian Dairy Feedpads and Freestalls (O’Keefe et al. 2010). While some of this information is already over six years old, much of the civil engineering aspects has recently been updated (Dairy Australia 2008b). Guidelines tend to concentrate on statutory planning, siting and engineering design, animal health and welfare and farm safety issues with less emphasis on the day-to-day feeding and herd management of modern dairy production technology.

There are sometimes subtle differences between feedpads and feedlots. Although there is significant research on feedlots (generally beef feedlots), research in Australia on dairy feedpads is lacking. Many farmers are worried that if their feedpad becomes classified as a feedlot, they are likely to be inundated with additional legislation reducing their flexibility in system design and management. Hopefully this book will allay such fears.

This manual is written specifically for dairy farmers throughout Australia, although the key principles and practices are relevant in any dairy industry, be it another temperate developed industry, such as in New Zealand or western Europe, or a tropical developing one such as in South-East Asia. In addition, the topics covered will be equally useful for dairy advisers, industry policy makers and any group involved in training farmers (at technical farm apprentice level) or service providers (at university undergraduate level).

Although a major emphasis of this book is on herd and feeding management, rarely covered in previous guidelines and other printed material on feedpads, there are chapters with specific information on physical planning and construction of feedpads and effluent management. These chapters could be considered, in part, to duplicate those found in other guidelines such as SIRIC (2002), Dairy Australia (2008b) and O’Keefe et al. (2010), hence may be out of place in a book such as this. While it is hoped that virtually every dairy farmer contemplating the construction of a new feedpad or upgrading an existing one would find this book useful, it is unlikely that many would have previously perused all the technical guidelines cited above. For those who have studied the guidelines closely, we apologise for any unnecessary duplication, and trust that you can bypass these sections in the chapters while seeking new material relevant to your search. For those who are unfamiliar with the guidelines, these chapters should be of as much relevance as those on herd and feeding management. The incorporation of such chapters into this book has increased its size, but for the sake of presenting the whole story of feedpads for grazing dairy cows, please accept our justification for their inclusion.

Understanding the feedpad system

Feedpad systems are a lot more than just the actual area where the cows stand to eat. They include all structures associated with maintaining stock away from paddocks, such as the feeding area, feed ingredients storage and preparation areas for mixing rations, laneways, loafing areas and of course, effluent system. These many components to the feedpad system can be likened to different rooms in a house. The area where the cows eat can be likened to a dining room, their troughs or feeding area to a dining table. The lounging area where cows can relax, ruminate or lie down is akin to a lounge room, or a bedroom. Feed is stored in a pantry, or the feed storage area, and the mixing area is analogous to a kitchen. The hall is like the laneways through which cows walk to and from the milking shed to the paddocks to the feed area. Feeding machinery is stored and maintained in a workshop. A roof provides some degree of climate control. Alas, there is no bathroom or toilet on a feedpad because unlike pigs, cows do not prefer to move to one area to urinate or defecate. The storage and disposal (or reuse) of treated sewe...