eBook - ePub

Fixed Biological Surfaces - Wastewater Treatment

The Rotating Biological Contactor

- 212 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Our objective in this book and in subsequent volumes of the Uniscience Series on Water Pollution Control Technology, is to provide a reference manual for design engineers, planners, and managers in industry and government. This is particularly important in the present critical period for implementation of water pollution controls.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Fixed Biological Surfaces - Wastewater Treatment by Ronald L. Antonie in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Environmental Management. We have over one million books available in our catalogue for you to explore.

Information

Chapter 1

Fixed-Film Biological Reactor the Trickling Filter

Introduction

While this book deals primarily with the rotating biological contactor (RBC) process, this first chapter is devoted to a discussion of the trickling filter process for the purpose of providing an overall background on the history and development of fixed-film biological treatment systems.

History and Fundamentals

The trickling filter process consists of a bed of rocks or synthetic media over which wastewater is uniformly distributed. After a short period of operation, a biological growth develops. The attached microorganisms remove suspended and dissolved organic material from the wastewater as it flows over the surfaces. At the same time, oxygen is absorbed from the air by the falling film of wastewater. The natural draft created causes air to flow upward through the media at the same time the wastewater passes downward.

The attached film of microorganisms is often defined to contain two distinctly different regions of activity. The effective film depth is that which is in immediate contact with the wastewater. In this region, dissolved oxygen and organic substrates are made readily available to the organisms by mixing and diffusion from the wastewater. The area between the filter media and the effective film depth principally consists of anaerobic organisms, because all oxygen is consumed before it can diffuse to the inner layer. The relative sizes of these two films depend on the concentration of oxygen in the wastewater film and the turbulence between the water film and the attached growth. One of the principal reasons for improved trickling filter operation with effluent recycle is the increase in the relative size of the effective film depth through increased oxygen concentration in the water film and increased turbulence with the attached growth.

Excess biological growth sloughs from the filter media and is carried out of the process by the wastewater flow. One of the principal mechanisms of sloughing in the trickling filter is the anaerobic activity at the interface with the filter media. Gas production together with loss of adhesion cause relatively large amounts of biomass to be stripped from the media surface in irregular intervals. Sometimes this irregular solids production is associated with organic overloads or changes in climatic conditions.

The first controlled use of fixed-film biological treatment of wastes occurred in England in the mid-19th century where wastewater was intermittently distributed over beds of sand.1 The principal function of the sand was to filter particulate matter from the wastewater, but it also served as a medium for attachment of microbial organisms which removed much of the nonfilterable organic matter. As the sand was later replaced by stone and an underdrain system was included, the treatment efficiency was improved. The wastewater then trickled down over bacteria-covered stones, and air passed upward to provide a continuous supply of oxygen to encourage aerobic biological activity. This system became known as the percolating filter in England and the trickling filter in the U.S. The name trickling filter has persisted to the present time even though filtration is no longer a mechanism of treatment in the process.

The first experimental use of the process in the U.S. was by the Massachusetts State Board of Health in 1889 where gravel was substituted for sand.2 Many of the early developments, including a spray system to distribute the wastewater and an underdrain system, occurred in England toward the end of the century. Commercial use of the process began in England just after the turn of the century and in the U.S. in 1908 when plants were constructed for the cities of Columbus, Ohio, Reading, Pennsylvania, and Washington, Pennsylvania. Use of the trickling filter increased steadily from that time.

During the 1930s the high rate trickling filter process utilizing effluent recirculation was developed. It permitted greater treatment capacities for the trickling filter. From that time until the 1950s, no further developments occurred. The activated sludge process was developed in the 1920s and gradually began to gain predominance over the trickling filter process. Trickling filters were in use in 3,506 municipal wastewater treatment plants in the U.S. in 1962 as reported in a Statistical summary issued by the U.S. Public Health Service in 1964. Of these plants, 2,135 employed standard filters, while 1,371 employed high-rate filters. The total population served by these facilities at that time was 23 million. For more details on the historical development of the trickling filter process, refer to Chase.3 A more recent report4 indicates that the total number of trickling filter plants is about 3,400, which serve about 30 million people. Apparently a number of the plants were expanded (or gradually overloaded) to serve more people, however, older plants were abandoned or converted to other treatment processes at a greater rate than new plants were built.

For further detail on the construction and operation of trickling filters, refer to Reference 2.

Problem Areas

The trickling filter process became readily accepted and widely used because of its simplicity and low operating costs, however, a number of economic and operating problems developed. The proper grade of stone could not always be found within a reasonable distance from the plant site, which significantly increased transportation costs. The type of stone often specified was “20-cycle” stone, which referred to the number of cycles of freezing and thawing the stone could withstand without deterioration. This specification was meant to provide stone which would last for 20 winter seasons, but in recent years, this specification has become very difficult to meet with reasonably available materials.

Problems of clogging by excess biomass have been experienced when using a trickling filter. This is caused by having too small an interstitial volume within the stones due to either too small a stone size or deterioration of the stones over a period of time. When clogging occurs, the wastewater channels through the media with little treatment. The clogged areas become anaerobic, generating objectionable odors, and are difficult to clear once they become clogged. Certain species of flies often breed in a trickling filter to cause a further nuisance.

Treatment efficiencies of a trickling filter decrease during winter operation because of excessive cooling of the wastewater and ice formation on the surface of the stones. Covering the trickling filter alleviates this only partially.

The principal reason for the gradual loss of popularity of the trickling filter is the limited degree of treatment achievable. The short wastewater retention time limits soluble BOD removal to the extent that it cannot meet the levels of treatment possible in an activated sludge system with a much longer retention time. With effluent discharge requirements becoming more stringent, the trickling filter could no longer compete economically with the activated sludge process.

Synthetic Media

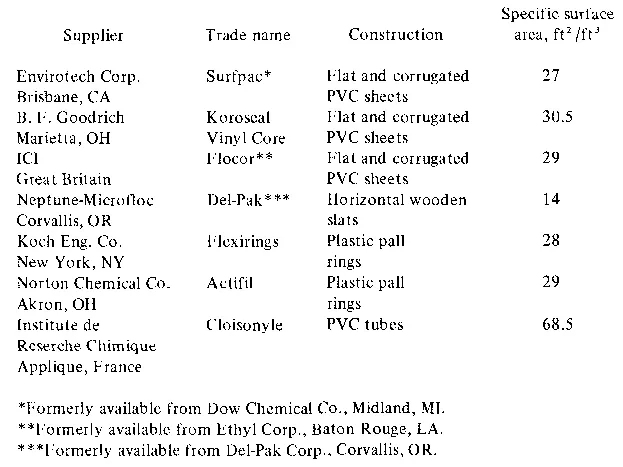

In the mid-1950s, a synthetic plastic media was developed which promised to solve many of the problems of the trickling filter. The initial work reported by Dow Chemical Company in 1955 evaluated a modified berl saddle design and a corrugated sheet construction of polystyrene. They subsequently marketed the corrugated sheet design, then of PVC, under the trade name Dow Pac®. Since that time, several U.S. and European firms have begun marketing various designs of plastic media. One U.S. firm has also recently started marketing a media constructed of horizontal wooden slats. Table 1-1 compares some of the characteristics of these synthetic media.

The corrugated plastic media were widely accepted as a substitute for rock and consequently, interest was revived in the trickling filter process in the late 1950s and early 1960s. The wider openings it provided reduced the danger of plugging, which alleviated many of the problems associated with plugging of the stone media. Its lower weight allowed the media to be stacked to greater heights and reduce construction costs and land requirements albeit at the increased cost of pumping wastewater and effluent recycle to greater heights.

Several companies who supply plastic tower packings in the form of Pall rings to the chemical processing industry have recently begun selling them as a trickling filter media. While in principle this form of synthetic media will work, it still has the major disadvantages of the rock media, i.e., small interstitial openings with their tendency to plug and limited depths of packing because of the inability to support the increased weight when covered with biomass. Because of this, they have received limited use.

Although some of the largest trickling filter plants have been built in recent years, the use of the trickling filter is steadily decreasing. This has resulted from the inability of the trickling filter to consistently achieve high degrees of soluble BOD removal while effluent standards have become increasingly more stringent. Because of this, some state regulatory agencies no longer allow trickling filters to be used as the sole means of secondary treatment.

TABLE 1-1

Types of Synthetic Media

Types of Synthetic Media

In the past, an existing rock trickling filter plant was often upgraded with synthetic media. Now with more stringent effluent standards, a different treatment process must often be substituted to assure that these standards will be ...

Table of contents

- Cover

- Title Page

- Copyright Page

- Dedication

- Table of Contents

- Chapter 1 Fixed-film Biological Reactor — The Trickling Filter

- Chapter 2 The Rotating Biological Contactor-History and Process Fundamentals

- Chapter 3 Process Development

- Chapter 4 Design Criteria — Domestic Wastewater Treatment

- Chapter 5 Upgrading Existing Treatment Plants

- Chapter 6 Design Criteria — Industrial Waste Treatment

- Chapter 7 Process Equipment Configurations and Plant Operation

- Chapter 8 Operating Experience

- Chapter 9 Capital and Operating Costs

- Chapter 10 Future Developments

- Appendix

- Index