- 284 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

CRC Handbook of Applied Thermodynamics

About this book

This practical handbook features an overview of the importance of physical properties and thermodynamics; and the use of thermo-dynamics to predict the extent of reaction in proposed new chem-ical combinations. The use of special types of data and pre-diction methods to develop flowsheets for probing projects; and sources of critically evaluated data, dividing the published works into three categories depending on quality are given. Methods of doing one's own critical evaluation of literature, a list of known North American contract experimentalists with the types of data mea-sured by each, methods for measuring equilibrium data, and ther-modynamic concepts to carry out process opti-mization are also featured.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access CRC Handbook of Applied Thermodynamics by David A. Palmer in PDF and/or ePUB format, as well as other popular books in Physical Sciences & Thermodynamics. We have over one million books available in our catalogue for you to explore.

Information

Chapter 1

Thermodynamics and Physical Properties in Process Innovation

TABLE OF CONTENTS

- I. Introduction

- II. Importance of Physical Properties

- A. Gas Processing Industry Examples

- B. Chemical Industry Examples

- C. Physical Properties in Data Bases

- D. Importance of Experimental Physical Property Data

- E. Summary

- III. Organization of the Book

- A. Section I: Probing Research

- B. Section II: Process Assessment

- C. Section III: Process Development

- D. Section IV: Applications

- References

I Introduction

New process innovation does not end when a new product or process chemistry is discovered. Design of the reactor and subsequent downstream processing must also receive careful attention. It is often necessary to do a significant amount of inventing in order to extract economically the desired product from the reactor effluent, recycle unreacted raw materials, and minimize pollution problems. Otherwise good chemistry sometimes has been abandoned for lack of creative application of separations technology. Sometimes, application of phase equilibrium technology is required just to make the chemistry work.

In this book the issue of phase equilibrium will be carefully considered because of its great impact on the feasibility and cost of chemical processes. Its evaluation requires use of thermodynamics; likewise, thermodynamics can be used to evaluate the reactions which form the basis of most chemical processes. Those who specialize in these areas must of necessity also be knowledgeable in physical properties. Physical properties of the pure compounds and mixtures are at the root of the phase equilibrium characteristics of systems; for example, the vapor pressure is extremely important in distillation. Other physical properties used for process design are thus the natural province of those who specialize in thermodynamics.

II Importance of Physical Properties

It sometimes seems that national security must be threatened to obtain concerted effort by a democratic nation. It was primarily the progress of science that finally ended the war with Japan. An almost forgotten element of the development of the atomic bomb relates to the race between the Allies and Germany to bring it to fruition. There were several ways to develop such a bomb. The short way required knowledge of a physical property of graphite. The Germans guessed at the answer, and guessed incorrectly. As a result they were led on the longer path of development of heavy water in Norway. The Americans knew of the German guess, but measured the physical property. They found that it was substantially different from the guess of the Germans, and were able to devise a much faster route to production of a nuclear weapon.1,9 If this scenario had been reversed, the U.S. might have become a province of the Third Reich!

Accurate physical properties are at the cornerstone of physics, chemistry, and engineering. Those disciplines have created the comfortable standard of living which many people in the world now enjoy. Petroleum and petroleum products fueled great changes during the first half of this century. Most people overlook the fact that the tractor freed the manpower resources of this nation to concentrate on manufacturing and service industries. Development of nitrogen fixation, which required an understanding of thermodynamics of ammonia, made possible dramatic increases in land productivity. Further great increases in agricultural productivity were due to the now maligned but absolutely essential pesticide industry. Applied chemistry has spurred other important industries: plastics of every variety, synthetic fibers, pharmaceutical chemicals, adhesives, microelectronics, advanced composites, and others. American leadership in these and other technologies has made the U.S. the strongest nation on earth.

It is a common perception that foodstuffs are our primary export, yet chemical exports in 1981 more than doubled in value the food exports!2 Statistics from the same source on national income arising from manufacturing show the following for chemical and related industries.

| ($ billions) | |

| Chemicals and allied products | 41 |

| Petroleum and coal products | 34 |

| Plastic and rubber products | 17 |

| Textiles and apparel | 30 |

Together, these industries represented 22% of total U.S. industrial production in the reporting year of 1982. A National Academy of Sciences report noted that the chemical industry provided a $12 billion positive international trade balance — second highest of all commodity groups.10

The direction of growth among U.S. industries is also of significance. The data indicate that the fastest-growing major industries are chemicals and related products. An industrial production index using a base year of 1967 was established; then the first half of 1983 was used to rate the various industries. Does it come as any surprise that the primary metals industry had declined by 21%, or that the fabricated metal products industry had increased only 13% in the 15 years of this study? All durable goods had increased only 27% in that time span. Nondurables, by contrast, increased by 61%; most chemical products fall into that category and grew by 105%! Leading all industry groups was the plastics/rubber segment, which expanded by 173%.

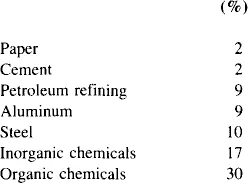

The chemical and petroleum industries are leaders in capital investment. In 1982 they were responsible for 45% of the $99 billion in manufacturing investment. Much of that investment is related to energy conservation and replacement of inefficient processes with more efficient ones. This can be illustrated best by a table of energy savings per constant dollar of value added. The time frame studied was 1971 to 1977, and it is quite certain that the trend has continued.

It is clear from these data that the chemical industry has been a leader in energy conservation. This has been made possible through process improvements, increased capital investment, and — at the root of all these changes — physical property data. Yet there is much potential improvement remaining.

The chemical industry generally recognizes that “the road to successful innovation and efficiency is paved with pieces of accurate physical property data cemented together with good correlations”. This involves more than fine tuning and optimization; it goes to the heart of process development. It involves the choice of unit operations as well as the size of equipment. It can be the key to development of a breakthrough process or failure to do so. Several examples follow for the gas processing and chemical industries.

A Gas Processing Industry Examples

M. A. Albright (see References 3 and 4) of Phillips Petroleum Co. has given several good examples of costly failures due to use of inadequate vapor-liquid equilibrium data.

Twenty years ago, gas processing recovered about half the propane plus the heavier hydrocarbons. But the demand for LPG was growing. The lean oil absorption process then pervasive wouldn’t do better. So, plants were built using refrigerated oils to recover more propane. As the level of refrigeration went colder, however, the plants recovered far less propane than predicted by design. Why? Because they were based upon projections from warm data to cold which were wrong. So the pressure was increased. This helped sometimes but not always and helped less than predicted. Again — wrong extrapolations. Why? Because the closure of the dew point curve and the bubble point curve to a critical [point] was either not recognized or was done so poorly. Once the data were measured and the problems recognized, it was shown that absorption could never accomplish the design goals.

The next step was the development of cryogenic plants where propane plus [heavier hydrocarbons] were recovered by condensation. All went well for a while. Then the market for ethylene for polymers exploded. It became desirable to recover ethane. So, colder plants were designed. Suddenly these did not meet design goals. Why? Because the effects on the phase behavior below the methane critical point were not recognized. Fortunately, data measurements were in progress and this problem was soon resolved . . .

Interestingly, the first big LNG plants, built in Algeria, were failures and required much redesign and rebuilding. Why? Because improper phase relation predictions caused an attempt to violate the second law of thermodynamics in the heat exchange train.

A recognition of the strides that could be made by having improved physical property data led the gas processing industry to form a cooperative research program within the Gas Processors Association (GPA). It has used the leverage of cooperative research dollars to pay for measurement of a significant amount of data. It has also developed to industry standards several equations of state. Industry experts believe that this work has resulted overall in an increase of 60% in extraction plant capacity.

Some gas and oil production companies are achieving enhanced recovery of petroleum using carbon dioxide flooding. The prediction of the effects of such miscible gas flooding on reservoir properties has required the use of sophisticated equations of state. Data for determination of the interaction parameters have been measured by several organizations, including but not limited to the National Bureau of Standards (NBS), Texas A & M University, and the American Institute of Chemical Engineers’ (AIChE) Design Institute for Physical Property Data (DIPPR).

A study by Air Products and Chemicals Inc. for a nitrogen rejection plant indicates that equipment size is very sensitive to the accuracy of the thermodynamic values.5,8 An uncertainty of just 5% in the K value of methane affects the heat exchanger size by 33%. Similarly, a 10% uncertainty in the nitrogen heat of vaporization resulted in a $2 million/year product loss in a standard-size plant. Inaccuracy of available data on light gases resulted in considerable oversizing of a hydrogen recovery plant built in 1961. Subsequent efforts to measure data accurately and develop better correlations have allowed reductions of 40% in capital cost for the same size of plant.

B Chemical Industry Examples

The chemical industry faces a different set of challenges due to the great variety of molecules that it must process. When one considers the enormity of the problem facing engineers with respect to mixtures, the successes enjoyed thus far are remarkable. Consider, for example, the successful design and operation of units to produce high-octane aviation gasoline and synthetic rubber during World War II. Much of the credit would have gone to data measured by Standard Oil of New Jersey and M. W. Kellogg Company, as well as to “new and improved” correlations6 of that time.

The successful design of plants for the extractive distillation of butadiene also has required considerable expertise and judgment. Consider the complexity of the feed to one of these plants. A total of 153 important binary mixtures can be identified, and composition effects are important. Then there are the thousands of combinations of multicomponent interactions. Thermodynamics experts have made phase equilibrium measurements on selected systems and used good correlation tools to solve an otherwise intractable process simulation problem. The process development relied more on physical properties work than on unit operation testing. Such men as Dr. Cline Black and Dr. Carl Deal played leading roles in development of the important sulfolane aromatics extraction process and the acetonitrile/water mixed-solvent extractive distillation process licensed by Shell Development Co. Development of models for such complex systems is illustrated in Chapter 8.

Dr. D. Zudkevitch6 of Allied Corp. reports that in the early 1960s a major engineering company captured a large share of the ethylene plant business. One of the tools used was the development of a physical property data base better than others in the industry. The company was able to redesign, revamp, and reorient the way that gases are handled coming out of the cracking section reactors. As a result, the cost of the recovery section was reduced, making an enormous difference in the overall plant cost. Mr. S. B. A...

Table of contents

- Cover

- Title Page

- Copyright Page

- Contents

- Foreword

- Preface

- The Author

- 1 Thermodynamics and Physical Properties in Process Innovation

- Part I: Probing Research

- 2 New Chemical Reactions

- 3 Scoping Process Development and Design

- Part 2 Process Assessments

- Index