Sheet Metal Forming Optimization

Bioinspired Approaches

- 234 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

Automotive and aerospace components, utensils, and many other products are manufactured by a forming/drawing process on press machines of very thin sheet metal, 0.8 to 1.2 mm. It is imperative to study the effect of all involved parameters on output of this type of manufacturing process. This book offers the readers with application and suitability of various evolutionary, swarm, and bio-inspired optimization algorithms for sheet metal forming processes. Book initiates by presenting basics of metal forming, formability followed by discussion of process parameters in detail, prominent modes of failure, basics of optimization and various bioinspired approaches followed by optimization studies on various industrial components applying bioinspired optimization algorithms.

Key Features:

• Focus on description of basic investigation of metal forming, as well as evolutionary optimization

• Presentation of innovative optimization methodologies to close the gap between those formulations and industrial problems, aimed at industrial professionals

• Includes mathematical modeling of drawing/forming process

• Discusses key performance parameters, such as Thinning, Fracture, and Wrinkling

• Includes both numerical and experimental analysis

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Introduction to Metal Forming

1.1Introduction

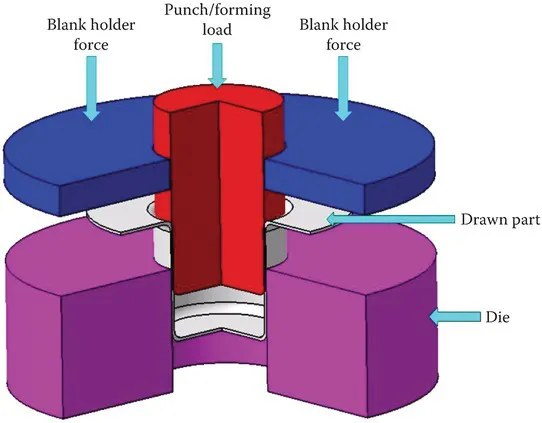

1.2Drawing/Deep Drawing Process

Deep drawing process—schematic representation.

Table of contents

- Cover

- Halftitle Page

- Title Page

- Copyright Page

- Contents

- Preface

- Authors

- 1. Introduction to Metal Forming

- 2. Process Parameters in Drawing

- 3. Failures in Drawing

- 4. Engineering Optimization

- 5. Thinning Optimization: Cohort Intelligence

- 6. Springback Optimization: Flower Pollination

- 7. Fracture Optimization: Genetic Algorithm Approach

- 8. Thinning Optimization of Punch Plate: Gray Wolf Optimizer

- 9. Wrinkling Optimization: Firefly Algorithm

- 10. Thickness Gradient Optimization: Ant Lion

- 11. Springback Optimization: Cuckoo Search

- Appendix A

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app