1 | Fundamentals of Water ElectrolysisXiaoxia Yan, Rida Javed, Yanmei Gong, Daixin Ye, and Hongbin Zhao |

CONTENTS

1.1 Importance of Water Electrolysis in Energy Storage and Conversion

1.2 Brief Introduction of Water Electrolysis

1.2.1 Alkaline Water Electrolyzer

1.2.2 Polymer Electrolyte Membrane Water Electrolyzer

1.2.3 Solid Oxide Electrolyzer Cell

1.2.4 Solar Relevant Electrocatalytic Technology

1.3 Recent Development of Water Electrolysis

1.3.1 Nanostructure Construction

1.3.2 Crystal Phase Adjustment

1.3.3 Crystal Face Regulation

1.3.4 Heteroatomic Doping

1.3.5 Hybrid of Materials

1.3.6 Mechanical Alloying

1.3.7 Polymer Surface Modification

1.4 Fundamentals of Water Electrolysis

1.4.1 Scheme Structure of Water Electrolysis

1.4.2 Electrochemical Process of Water Electrolysis

1.4.2.1 Hydrogen Evolution Reaction in Water Electrolysis

1.4.2.2 Oxygen Evolution Reaction in Water Electrolysis

1.5 Summary

References

1.1 IMPORTANCE OF WATER ELECTROLYSIS IN ENERGY STORAGE AND CONVERSION

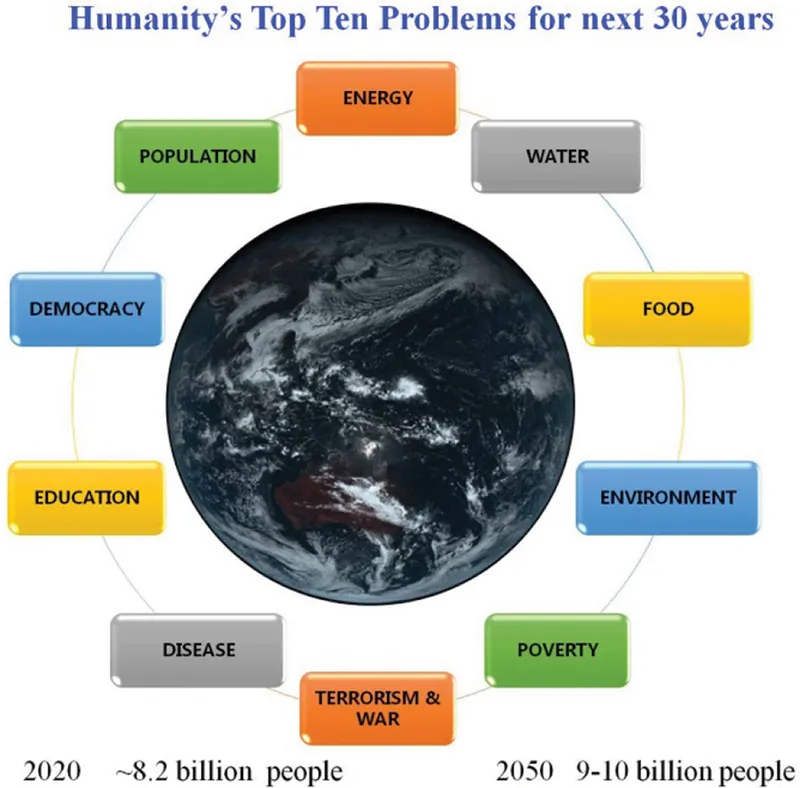

The massive utilization of fossil and nuclear fuels represents serious environmental threats such as natural resource exhaustion, pollutant gas emission, waste generation, and climate change. As a result of the public awareness of this reality, an agreement has been reached in the sense that a novel, clean, sustainable, and renewable resources-based energy system is needed. However, the temporal and spatial intermittencies of the current renewable energy resources such as solar, wind, geothermal, etc. induce low energy delivery efficiencies and restrict daily applications. Converting these energy resources into chemical fuels that can be easily stored and transported is a prospective solution. Hydrogen can be produced from the electric energy generated by hydropower, wind, and photovoltaic systems in many different applications, which can be easily coupled with water electrolysis processes producing clean and sustainable hydrogen (Figure 1.1).1

Hydrogen technologies can help us to cope with these challenges and to contribute to the new energy system development.2,3,4 It is well known that hydrogen is the simplest and lightest chemical element of the periodic table. Its density as a gas (0.0899 kg/Nm3) is 15 times lighter than that of air. It is also the fuel with the highest energy content per mass unit, being its higher heating value 3.54 kWh/Nm3 (39.42 kWh/kg), that is, 2.5 and around 3 times more energetic than methane and gasoline, respectively. However, hydrogen cannot be found in its pure state in nature even though hydrogen is the most abundant element in the universe. Actually, up to 96% of hydrogen is produced from fossil fuels such as natural gas, oil, and coal; and the other 4% from water.5,6 In the long run, it is not a sustainable way to produce hydrogen from hydrocarbon sources. Hydrogen is highly desired to be produced by clean and environment-friendly processes, thus avoiding the emission of pollutants.7 Furthermore, water is widely agreed to be the most interesting source of sustainable hydrogen of the future mainly because it is a renewable source and the process is easy to be integrated with renewable energy sources.

At the beginning of gas production, hydrogen has been generated mainly from an industrial steam reforming process that converts natural gas with water into carbon monoxide and hydrogen, but the low energy efficiency of the conversion process and the presence of carbon-containing residues result in the high cost and low purity of the hydrogen products, respectively.8,9 An alternative technique of producing hydrogen is via water splitting by electricity or sunlight, which benefits from the abundance of water resources and gives high purity owing to high reaction selectivity. In this case, the main production method is the electrolysis, although thermal and photocatalytic decompositions are also attracting some attention.

Water electrolysis is to date the most important method to obtain large amounts of hydrogen from water with neither the emission of pollutant gases nor the consumption of fossil or nuclear resources.5,10,11,12,13,14,15,16,17 The technology is mature based on the productions of hydrogen and oxygen by applying a direct electric current to split water. The obtained hydrogen by electrolysis has a relatively high purity that can reach up to 99.999 vol% when the generated hydrogen has been dried up and oxygen impurities have been removed. Such high purity is of great advantage against both fossil fuels and biomass-based processes because the electrolytic hydrogen production is proper for being directly supplied in fuel cells.

1.2 BRIEF INTRODUCTION OF WATER ELECTROLYSIS

Water electrolysis technologies can be classified according to the applied electrolyte, which separates the two half reactions at the anode (oxygen evolution reaction) and cathode (hydrogen evolution reaction) of the electrolyzer. Several main types of water electrolysis systems for hydrogen production will be briefly introduced as follows:

1.2.1 ALKALINE WATER ELECTROLYZER

The alkaline water electrolyzer (AWE) system is usually composed of an anode and cathode, which is immersed in an alkaline solution, generally 20%–30% potassium hydroxide (KOH).18 They operate at a temperature below 100°C and atmospheric pressure. In this system, a diaphragm is needed for separating the two electrodes (anode and cathode). The diaphragm conducts hydroxide ions (OH−) through a KOH solution, which keeps hydrogen and oxygen separated to prevent their recombination. The partial reaction at the electrodes is given by19:

For hydrogen production, alkaline electrolysis represents a mature technology (up to megawatt range) at the commercial level, which has been applied for large-scale hydrogen production in the beginning of the twentieth century. However, some drawbacks still exist in the system because the diaphragm leads to high ohmic loss across it and limits the maximum current density. Moreover, the diaphragm cannot generate enough current to keep the hydrogen and oxygen from mixing. Therefore, a high pressure cannot be achieved, which would otherwise be beneficial for a bulky stack design. In addition, the permeation of gas products makes hydrogen and oxygen mix and recombine, and decreases the Faraday efficiency. Despite these dis...