![]()

SECTION 1

The Pivotal Moments

![]()

1

The First Pivotal Moment: I Tolerated Safety

If I have to wear these things, you have to!

– My foreman to me when he caught me not wearing my safety glasses

The first pivotal moment, which was my first exposure to occupational safety and health, came during my first job after high school graduation in 1977. I worked at a glass bottle factory in Hapeville, Georgia, on the south side of Atlanta. I went to work there because that is where my dad worked as well as so many other members of my family, so it seemed natural to follow suit. Besides, I did not feel like college material.

At the time, most containers were made of glass: milk jugs, Gatorade bottles, prescription bottles. After the bottles went through the cooling process, decorating and packaging, my job was to take the boxes off the conveyor and stack them on a pallet.

By the time the bottles reached me, they still radiated heat from the forming process. The conveyor moved at a steady pace and did not stop for breaks. My motion was constant. It was not a frenzied pace, but it was steady and it was hot, always hot. I also remember the factory being noisy, although I do not recall wearing hearing protection. Broken glass on the floor was a constant as were people assigned to sweep up the broken glass.

I do not recall any specific safety training as part of my orientation. I also do not recall being placed under the tutelage of a senior employee. I suppose the knowledge required to take a box of bottles off a conveyor and place them on a pallet did not take a great deal of training. The plant had a requirement to wear eye protection while on the factory floor due to flying glass chips. Work shoes with thick soles were necessary. The eye protection was supplied by the company seemingly without consideration to fit. Further, the plant was hot and the glasses tended to slide down my nose. The problem was compounded the more I sweated. So, I did what any good junior employee would do in this situation – I learned from the senior employees. They clinched the stem of the glasses between their teeth and quickly put them on when they saw the inspector or foreman on the floor. I soon mastered that maneuver. That worked great until one day, the foreman walked up from behind me. The foreman had a crew cut and stood over 6 ft. tall. He reminded me of a drill sergeant. He tapped me on the shoulder and said in no uncertain terms, “If I have to wear these things, you have to wear them. Put ’em on!” His words and tone still ring out in my mind today. That was the first pivotal moment that shaped my perception of safety. It was not a positive experience.

Safety was something I had to do. I learned to tolerate safety at best. It was something I endured. It was boring and aggravating. I did not appreciate or even see the benefits; it was enforced because we had to, not because we wanted to. Safety was and still is often thought of as a negative. Terms like “accidents,” “investigations,” “disciplinary action,” “citations” and “penalties” all conjure up negative thoughts and images. There are different methods for selling safety, and that was one ineffective method, although it ensured we met minimum standards at least most of the time.

Safety continued to be something I looked out for, not because it protected my well-being, but because I knew I would feel the wrath of the foreman if I was caught being non-compliant. That perception of safety stayed with me for several years. Unfortunately, there was so much around me that reinforced my negative image of safety. Other issues were seemingly more important, like the relief guy showing up on time so I could take my break, and if my paycheck accurately reflected my overtime. Safety just did not rank as anything important to anyone, including me.

![]()

2

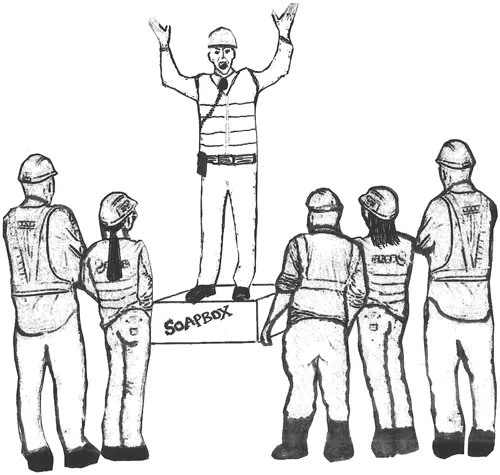

Soapbox Safety

That CANNOT happen again or you WILL get written up!

– Me, as a supervisor to my team after an incident.

I worked long enough at the glass factory to figure out that a college degree just might serve me well. I headed to college and studied business administration. Before graduating, I landed a summer job in the airline industry at the Atlanta airport. I was excited!

The airport ramp environment was a hectic cluster of aircraft, motorized vehicles of all sorts, rolling stock (used for hauling cargo, airmail and baggage) and people. There were baggage tugs, jet tugs, belt loaders (motorized conveyors), fuel trucks, lavatory trucks, catering trucks, maintenance lift trucks and water trucks, all designed to service an aircraft quickly. Pedestrians constantly intermingled with vehicles – sort of a concrete, motorized version of the wild, wild west. Break areas were like the saloons. They emptied out directly onto the ramp where your horse (bag tug) was tied up.

Baggage, cargo and mail had to get loaded on the correct flight at the right time. Flights arrived in “pushes”; in other words, they were not spread out evenly over the day. They arrived and departed in banks of flights similar to traffic jams in the morning and afternoon. Lockheed L1011 Tri-Star, Boeing 727, McDonald Douglas DC-9 and DC-8 aircraft filled the ramp. At the time, there were no traffic lanes to streamline vehicle traffic flow, no red lights to direct vehicle traffic and no safety officers to direct aircraft, vehicles or pedestrians. Only the people in the flight control tower were directing aircraft. As a pedestrian on the ramp, you were on your own, sort of a buyer beware situation since aircraft pilots do not have a clear view of the ground, and even if they did, at around 114,000 kg (250,000 lbs), aircraft cannot exactly stop on a dime. With engines that can produce 180,000 kg (400,000 lbs) of thrust, creating suction at the engine intake (front of the engine), the ramp environment was a dangerous place to work.

My job was to load baggage, cargo and airmail in a timely manner. I received about one week of classroom training before stepping out on the airport ramp. I still vividly recall my training on the hazards of Aircraft Engine Blast and Suction. You cannot see it and only barely hear it (we wore hearing protection), but it was ever-present. It was a silent killer. Stories of severe accidents resulting from blast and suction stayed with me. With so much aircraft and vehicle noise, all sources of noise became just white noise. Unless you saw trash or dirt being kicked up by jet blast, you may not notice that an engine was running. We were taught to look for the red blinking lights above and below the fuselage, which indicated the engines were running. The lights indicated the presence of jet blast and suction hazards, but that was just one more thing to look for.

I was paired with a “buddy” and told to “stick close to Rick” for a couple of weeks. Rick was a senior guy with an interest in mentoring (and patience). It was Rick’s job to show me the ropes, assess my performance and let supervision know when I was ready to stand on my own in this airport version of the wild, wild west.

As part of my informal “buddy” training, Rick escorted me out to the middle of an aircraft taxiway and pointed to a specific spot and said, “Stand here.” Rick did something that morning that has stayed with me to this day. He told me the story of a horrific accident involving another “summer help” worker who was run over by an aircraft. My “buddy” Rick taught me many lessons over the course of the next few days, but nothing stuck with me like that message. His message stuck with me because it was conveyed in a story. It was a story that I easily identified with as a new employee and teenager.

My job orientation did not stop there. Rick showed me the perspective from the ground and from the flight deck of an aircraft. He emphasized the obstructed view from the pilot’s perspective and the noise on the ramp (aircraft engines easily exceeded 90 dBs at the time) that hindered my ability to focus. The noise essentially took away one of my senses, effectively reducing my ability to hear and thus anticipate changes that may present new hazards. His message was simple: be on the alert for these hazards (moving aircraft). Recognize that your environment (high noise, weather conditions, congestion) will change and hamper your ability to recognize hazards. I eventually went on to work around aircraft for the next 13 years with a very healthy respect for the environment and hazards.

After my brief stint as a “summer help,” I worked several hourly jobs including janitor (I cleaned bathrooms in the aircraft hangars), forklift operator, aircraft cabin cleaner, lavatory truck driver (yes, it is what it sounds like) and baggage handler where my job was to load and unload bags and cargo from aircraft. I eventually worked my way up to ramp area supervisor. I was responsible for managing the workload, communicating plans and personnel scheduling for an area that covered about 4–5 gates and about 30–45 employees.

Every company has a culture often defined by at least one or two metrics that drive action. In the airline industry, after passenger safety it was on-time performance. The US Department of Transportation (DOT) published results every month in the form of a ranking by airline. These results drove a real sense of urgency based on your rank. On-time performance drove our culture; it is what management paid attention to and talked about, and often yelled about. If you were responsible for a flight delay, you had to explain verbally and in writing up the ladder and hope they accepted your explanation. Departments argued over who was responsible for a delay. It created a sub-culture of blame similar to the safety culture. “It can’t be my fault, so who can I blame?”

Our safety culture at the time could be summed up in one phrase: “whatever it takes to get the job done!” It translated to mean “whatever it takes to the get flight out on time.” If someone suffered an occupational injury, well that was just the cost of doing business. The protocol was to send the injured employee for medical attention (we had a nurse on-site) and home until fully recovered. Light or restricted duty was not offered at the time.

Aircraft damage prevention was the primary focus of the safety initiative. Repairing an aircraft struck by a motorized vehicle was expensive. In addition to direct costs associated with the repair, there were delay costs. A delayed flight had a domino effect. One flight delayed impacted subsequent flights later in the day. Passengers had to be rebooked or overnighted if another flight was not possible. The brand also took a hit. Frequent flier surveys always listed on-time arrival as very important, not to mention the safety implications of flying a damaged aircraft. If an aircraft was damaged and it resulted in a delayed flight, and it almost always did, all hell rained down from above. I called it “Soapbox Safety.” At the supervisor’s shift briefing the next day, the boss mounted the soapbox and preached, berated, cussed and fumed about our lack of diligence and care working around aircraft. As a young supervisor, I followed suit. I went back to my area, got on my soapbox and preached and yelled and cussed. It started somewhere around the top and worked its way down. I learned how to manage safety from their example (Figure 2.1).

Figure 2.1 Soapbox Safety. Illustration by Masha Balac.

We had two “safety” tools in our arsenal: “soapbox safety” was the first and the second was disciplinary action. It was progressive and worked something like this:

- First offense – a letter of reprimand is placed in the employee’s file

- Second offense – one day off and a letter of reprimand is placed in the employee’s file

- Third offense – three days off and possible demotion or termination.

Offenses typically meant aircraft damages. Employees were not disciplined for incurring an occupational injury. After all, it was a tough, physical environment and injuries were likely, if not expected, to occur. As a supervisor, if I had a team member out of work due to injury, I covered the workload by paying overtime. I became somewhat of a hero for the moment when I could offer overtime to someone looking to make a few extra bucks. Word would get around pretty quick, “Hey, PK has a couple of folks out on injury and is paying OT this week.” It is what I call a disincentive to injury prevention.

But that one-two punch is essentially how I managed safety as a front line supervisor on the ramp. Yell a lot, cuss some, hand out disciplinary action when necessary. What was amazing about this one-two punch was that it worked … at least for a few weeks. Sooner or later the whole scenario was repeated.

To sum it up, on-time performance was the key metric. Aircraft damage impacted on-time performance; therefore, the prevention of aircraft damage was managed aggressively and drove the safety culture. Arbitrating over a safety incident and sentencing employees to disciplinary action gave the illusion that my management style was working. In reality, that punishment was only improving performance to minimum standard levels and leaving the employee with a negative experience. I talk more on safety as positive in Chapter 8.

![]()

3

The Second Pivotal Moment: Safety Becomes Personal to Me

I heard the call come over my radio, Echo 1 to gate A-17…

The second pivotal moment came more than 10 years later. I was a supervisor working the evening shift, 3:30 pm to midnight. About 12 supervisors were on duty spread out over the Atlanta airport, an airport that at the time spanned across six concourses, four runways (today five) and one terminal (today two). Then, it was one of the busiest airports in the world and covered over 4,000 acres. Since 1998, i...