- 120 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

This design guide was written to capture the author's practical experience of designing, building and testing multi-rotor drone systems over the past decade. The lack of one single source of useful information meant that the past 10 years has been a steep learning curve, a lot of self-tuition and many trial and error tests. Lessons learnt the hard way are not always the best way to learn. This book will be useful for the amateur drone pilot who wants to build their own system from first principles, as well as the academic researcher investigating novel design concepts and future drone applications.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Introduction

The majority of RC component (Battery, ESC, BLDC Motor and Propeller) manufacturers do not state accurate empirical performance measurements for these vital parts. Those that do sometimes state inaccurate and/or inflated values, presumably to drive sales and to fool the unsuspecting consumer.

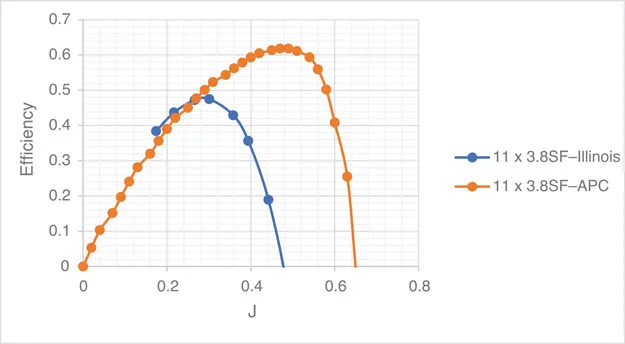

It is therefore vital for the user to seek corroboration of data online and/or conduct their own static thrust tests,1 before specifying and purchasing a complete system solution. A rare exception to this situation is the data provided by the US-based propeller manufacturer APC (Advanced Precision Composites) who provide computerised performance data on their full range of 493 propellers used in both fixed-wing and rotary-wing (multi-rotor) aircraft.2 However, unfortunately a recent comparison of UIUC wind tunnel data3 has shown this to over-estimate the maximum efficiency by up to 14%, as can be seen in the figure below for the APC 11" × 3.8" SF propeller running at 3000 RPM. Apparently, this is due to the NASA TAIR code4 that they use to predict the airfoil lift and drag. APC are looking into improving this code.

The majority of this design guide is focussed towards the optimum design of an all-electric multi-rotor configuration. However, many of the findings will be also applicable to small, fixed-wing aircraft.

Once a system configuration (Helicopter – single main rotor, tandem, coaxial), Bicopter, Tricopter, Quadrotor, Hexrotor, Y6, Octocopter, X8, etc.) has been chosen, it is important to draft a Preliminary Design Specification (PDS). This sets out the important parameters of the system design process.

Figure 1.1 Comparison of wind tunnel data with computerised data for an APC 11" × 3.8" SF propeller.

Given the design constraints of the IMechE UAS Challenge, two of the most important elements of the PDS, are the desired endurance (min) and the payload capacity (kg). A typical value for the maximum endurance of a small multi-rotor (< 7 kg) is 20 min; however, the best of class has an endurance of around 30–40 min (usually quoted without payload).

The ultimate goal should be to exceed the 1 hr endurance target, whilst carrying a payload of say, 5 kg, which would cover 90% of all current pay-loads. To achieve this, would require a design at an MTOM of approximately 15 kg, probably utilising a more exotic power source such as a Hydrogen Fuel Cell, Fuel Engine or Hybrid system.

In terms of payload capacity, most small multi-rotors (< 7 kg) are designed to carry a small payload of about 0.5–1 kg (max). Clearly, one of the goals of the IMechE UAS Challenge organisers was to push the boundaries of what is technically possible in terms of payload, endurance and autonomy.

Many commercial multi-rotors carry a small camera, which usually forms their payload. Improvements to these devices have allowed high definition (HD) cameras, with recording capability, to be incorporated into small, lightweight (< 30 g) and low-cost packages (< £ 30).5

Figure 1.2 The four main components of an RC electric aircraft propulsion system.

The aim of multi-rotor multi-objective design optimization (MDO) must therefore be to maximise the endurance, together with the payload capacity. By understanding the fundamental principles of each sub-system, it is possible to select the ‘best in class’ individual components. In the following chapters, each of the four main propulsion system components will be examined in detail, starting with the power supply and moving towards the propeller (rotor).

Notes

1 Dr Kiwi (2018) BLDC Motor/Prop Tests. Available from: www.flybrushless.com/user/profile/14

2 APC (2018) APC Prop Data. Available from: www.apcprop.com/v/PERFILES_WEB/listDatafiles.asp

3 UIUC (2018) Propeller Data Site. Available from: http://m-selig.ae.illinois.edu/props/propDB.html

4 APC (2018) Airfoil Design Data. Available from: www.apcprop.com/technical-information/engineering/

5 HobbyKing (2018) HD Camera. Available from: www.hobbyking.com/hobbyking/store/__17200__HD_Wing_Camera_1280x720p_30fps_5MP_CMOS.html

2

Lithium Polymer battery (power supply)

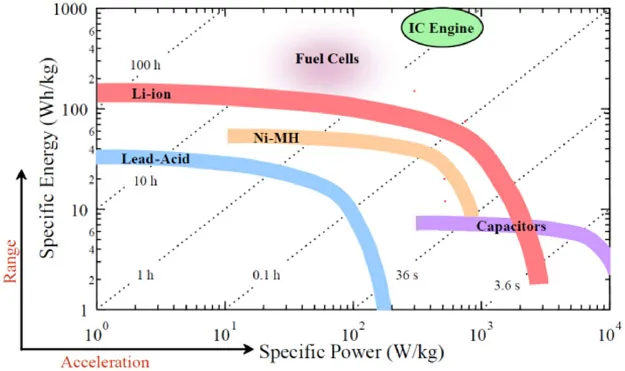

Lithium Polymer battery technology (with low internal resistance: typically 0.001 Ω) currently gives the highest Specific Energy (150–200 Wh/kg) of any type of rechargeable battery.1 Given the design requirement to supply high current, 40–150 A (continuous) at low voltage DC (typically 7.4–22.2 V), the Li-Po is a natural choice (see Appendix A). Li-Po batteries typically range from 10 to 120 C.

Tip 1: To calculate the max continuous current capability, multiply the ‘C’ rating by the capacity (Ah).

Rival systems such as Li-ion, Li-S, Hydrogen Fuel Cells (HFC), Super Capacitors and Photo Voltaic (PV) systems, etc., lack the high current draw capability, have refuelling/disposal issues, are large in size & mass and can be very expensive, making them impractical at this time. Having said that, if money is no barrier and you are willing to build a very lightweight UA, which is on the edge of its design envelope, you can achieve hover endurance for a multi-rotor in the region of 2–6 hr using these systems.2,3,4,5

- Li-Ion batteries (High SE (243 Wh/kg), very low (0.5–2) C-rating, 3.6 V/cell).

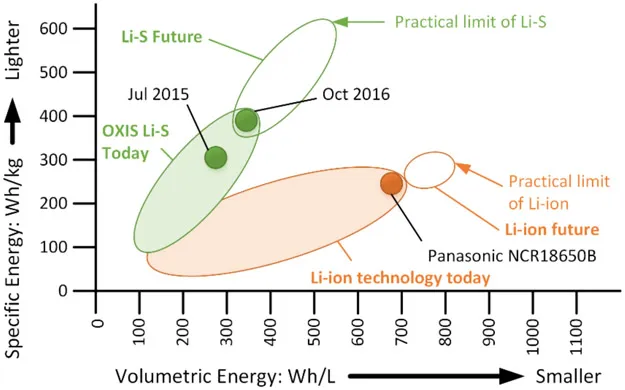

- Li-S batteries (High SE (400 Wh/kg), not commercially available yet, low C-rating, 2.1 V/cell).

- Hydrogen Fuel Cells (Very high SE (600 Wh/kg), high mass, large size, very expensive, pollution).

- Photo Voltaic (PV) – Solar (Low efficiency < 44%, large surface area (250 W/m2), low current).6

- Super Capacitors (High specific power, low specific energy, low cost and low mass).

- Directed Energy (Laser Power) (Low efficiency < 20%, line of sight operation, safety concerns).

- Nuclear batteries (Extremely high SE, very low efficiency, large mass, safety concerns).

In this context, an IC engine cannot be beaten from a Specific Energy standpoint (900+ Wh/kg); however, the drawbacks of high mass, fuel safety, heat signature, noise, pollution and vibration make this choice undesirable. However, recent hybrid IC Engine/Li-Po battery solutions have been shown to work.

Figure 2.1 Ragone plot of energy storage comparison in terms of performance (Srinivasan, 2008).

However, it is interesting to note that Petrol, as a fuel, has a Specific Energy of 12,200 Wh/kg; this puts all forms of rechargeable battery into perspective.7 That said, electric motors are nearly four times more efficient than IC Engines, so the equation is more likely to reach equivalence at 3050 Wh/kg. Given the extra mass of an IC engine, it has been stated that this could come down to equivalence at about 340 Wh/kg. The growth of all-electric vehicles, such as the Tesla range, is testament to this.

Figure 2.2 Comparison of Li-S batteries with other rechargeable battery types (Oxis Energy, 2018).8

Li-Po batteries come in all shapes and sizes from very small – 250 mAh – 50 g (1 Cell/1S) to very large – 30,000 mAh – 3.67 kg (6 Cell/6S) and are often designated as 6S1P, 3S2P, etc. (this refers to the number of cells in Series (increased voltage) and the number of cells in Parallel (increased capacity)). Each cell of a Li-Po battery is nominally ...

Table of contents

- Cover

- Title

- Copyright

- Dedication

- Table of Contents

- List of tables

- List of figures

- List of abbreviations

- General assumptions

- Design constraints

- Preface

- Acknowledgements

- 1 Introduction

- 2 Lithium Polymer battery (power supply)

- 3 Electronic Speed Controller (ESC)

- 4 The Brushless DC (BLDC) motor (outrunner)

- 5 The propeller (rotor)

- 6 The system solution

- 7 Conclusion

- Appendices

- References

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Optimizing Small Multi-Rotor Unmanned Aircraft by Stephen Prior in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Civil Engineering. We have over one million books available in our catalogue for you to explore.