eBook - ePub

Chitin- and Chitosan-Based Biocomposites for Food Packaging Applications

- 98 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Chitin- and Chitosan-Based Biocomposites for Food Packaging Applications

About this book

Chitin is one of the most important biopolymers, synthesized by an enormous number of living organisms and is a promising bioactive polymer for food packaging applications due to its functional properties. This book focuses on composition, properties, characterization, and theoretical approach of chitin and chitosan bio-composites. It describes the most recent studies concerning chitin and chitosan-based films and gives an overview about future trends regarding the industrial applications of chitin and chitosan for food packaging purposes. This book is especially useful for researchers in the fields of bionanocomposites, especially those with an interest in packaging applications.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Chitin- and Chitosan-Based Biocomposites for Food Packaging Applications by Jissy Jacob,Sravanthi Loganathan,Sabu Thomas in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Chemical & Biochemical Engineering. We have over one million books available in our catalogue for you to explore.

Information

Edition

1CHAPTER 1

An Overview of Biopolymers from Natural Resources

Grupo de Compósitos e Nanocompósitos Híbridos (GCNH), Department of Physics and Chemistry, Programa de Pós-Graduação em Ciência dos Materiais

São Paulo State University (Unesp), School of Engineering

Ilha Solteira, Brazil

1.1 Introduction

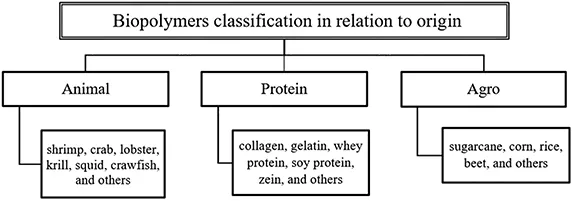

Biopolymers can be defined as any polymers (such as proteins and polysaccharides) originating from living organisms. They are mainly produced from carbon sources, usually carbohydrates obtained from large-scale commercial plants such as sugarcane, corn, potatoes, wheat, and beets—or other vegetables, for instance, the oil extracted from soybeans, or sunflower, palm, or other oleaginous plants (Steinbüchel 2003). Some biopolymers’ origins are shown in Figure 1.1.

FIGURE 1.1 Biopolymer Classification: Animal, Agro, and Protein Origins.

Biopolymers are promising candidates for use as matrices for packaging materials due to their exceptional capability of film-forming, biological properties, and excellent physicochemical properties (Wu et al. 2019). The application of biopolymers obtained from natural resources in food packaging is more promising. This is owing to the fact that these biopolymers are affordable, available in abundance, and renewable in nature (Shahabi-Ghahfarrokhi, Goudarzi, and Babaei-Ghazvini 2019).

1.2 Petroleum-Based Polymers—Challenges

In current society, dependence on synthetic polymers has increased over the years. Polyethylene (PE) and polypropylene (PP) are polymers obtained from polymerization reactions by using monomers obtained from petroleum derivatives (Pathak and Navneet 2017). In general, people use this polymeric class because of their desirable properties such as excellent mechanical properties, resistivity, and low chemical reactivity (Song, Murphy, Narayan and Davies 2009; Dey, Mondal, Das and Dutta 2012). However, some problems arise from the use of synthetic polymers. Their low response against different types of chemical/biological degradation creates a problem from the moment they are discarded. It is estimated that a simple plastic bag that one takes home from the supermarket requires about 450 years to degrade.

In recent years, the use of synthetic polymers has presented problems in relation to the crisis in the acquisition of petroleum resources, mainly in relation to cost, as well as an environmental concern.

Thus, biodegradable polymers have been a viable alternative to minimize this environmental impact. These materials began to be studied in the mid-1960s. Thus, bio-based matrices have been widely studied in order to replace synthetic polymers.

1.3 Biopolymers

One main advantage of substitution of biopolymers for petroleum-based polymers is that they are totally capable of biodegradation and break down into the simplest molecules, such as CO2, H2O, or CH4. This can occur by an enzymatic action initiated by microorganisms present in the environment. Polymeric matrices obtained from renewable resources may present biodegradability or may be compostable under controlled conditions. In industry, the application of biopolymers can be found in the most diverse areas. For instance, biopolymers are used to produce smart textiles using eco-friendly manufacturing processes.

1.4 Classification

Biopolymer fibers may classified as natural, regenerated, or synthetic and their use can contribute to reducing environmental pollution (Younes 2017). Biopolymers such as polycaprolactone (PCL) can be processed as spun fibers or manufactured to be applied in soft tissue engineering, or as electro-spun fibers and seat belts (Asadian et al. 2019). Natural biopolymer-based films or their nanocomposites have been studied extensively for packaging applications in the food industry (de Moura et al. 2009; Otoni et al. 2017; Nunes, Melo, Aouada, and de Moura 2018). Biopolymers based on hydrogels containing drugs have shown positive use in drug delivery (Fernandes, de Moura, Glenn, and Aouada 2018). Various other preparation methods have been used in the synthesis of biopolymeric hydrogels for possible applications in agriculture (Ferreira Junior, de Moura, and Aouada 2017; Tanaka, Ferreira Junior, de Moura, and Aouada 2018).

1.4.1 Agro Origin

Several authors described the extraction of polysaccharides from agroindustrial wastes. For instance, the extraction of both chitin and chitosan polysaccharides by Cunninghamella elegans and Rhizopus arrhizus strains from corn steep liquor− and molasses-based agroindustrial wastes was reported by Berger et al. (2014). Leite et al. (2015) described yet another effective route for extraction of chitosan from agroindustrial substrates such as corn steep liquor and sugar cane bagasse. The steps involved in the extraction process include deproteinization of agroindustrial wastes using NaOH, which is then followed by autoclaving and centrifugation. It is reported that the degree of deacetylation of chitosan is achieved to be ~80%. Additionally, the authors also documented that the chitosan acts as a fungicide against pathogenic yeasts. Hence, it is possible to expect that chitosan can be tested as a component of food packaging.

The main advantage of the use of chitosan from agroindustrial wastes in packaging over conventional materials, such as synthetic polymers is to reduce environmental pollution. It has low cost when compared to other synthetic materials. In addition, when used in the nanoparticulate state, it may act as an efficient additive for improving the physicochemical and barrier properties related to food packaging (Ramesh and Radhakrishnan 2019).

1.4.2 Animal Origin

Chitin is the second most plentiful polysaccharide on the Earth. Due to high crystallinity of strong hydrogen bonds and cohesive forces, chitin is practically insoluble in all regular solvents, including water and organic substances, affecting expansion of the processes for the preparation of chitin-based derivatives (Roy, Salaün, Giraud, and Ferri 2017). For instance, Younes and Rinaudo (2015) described various methods for recovery chitin from different marine organisms, including shrimp, crabs, lobsters, krill, squid, and crawfish, using NaOH concentration, temperature, and time as deproteinization experimental parameters, and HCl concentration, temperature, and time as factors in the demineralization process. According to the authors, chitosan is frequently obtained from chitin deacetylation. For the degree of acetylation that is inferior to 0.5, chitosan becomes soluble in several solvents, such as the aqueous acidic medium. Because of these solubility properties, several works have demonstrated the application of chitosan biopolymers in food packaging. Among different sources, those of agro, animal, and protein origin are the three main sources of obtaining biopolymers.

Chitosan biopolymers of animal origin are mainly found in animals lacking a backbone, such as arthropods, various insects and marine diatoms, and algae (Synowiecki and Al-Khateeb 2003). For instance, Islam, Khan, and Nowsad Alam (2016) extracted chitin from shrimp shell wastes and produced chitosan on a commercial scale from alkaline hydrolysis using NaOH. Recently, Hugo and Hugo (2015) presented a complete revision about the application of different animal-derived chitosans as natural preservatives in fresh sausage products. This study showed that chitosan acts against different microorganisms, increases the shelf life and reduces the lipid oxidation of boerewors and skinless pork sausages, and improves the quality of these products by acting as a food packing. According to Bilbao-Sainz et al. (2018), due to their interesting properties such as biodegradability, biocompatibility, and non-toxicity, chitosan is a polysaccharide with the potential to be applied in food coating. In this work, the authors produced coating using fungal chitosan and alginate by self-assembly. They found that the polysaccharide coating decreased the yeasts and fungal evolution, and improved the fruit bar shelf life, preserving the quality of these food products.

1.4.3 Protein Origin

The literature reports several composites, biocomposites, and nanocomposites formed from protein-chitosan films for food use. Collagen/chitosan composites plasticized by using glycerol have great potential for applications in this area because it presented satisfactory mechanical, transparency, solubility, and thermal properties (Ahmad et al. 2016).

Different strategies have been employed to improve the chitosan-based product characteristics. Qu et al. (2019) observed that the TiO2 nanoparticles increased the tensile force of the zein/chitosan nanocomposites, reaching around 28 MPa at 0.15 wt % TiO2 nanoparticles. It was also observed that these nanocomposites had an antibacterial effect on gram-positive bacteria (S. aureus) and gram-negative bacteria (E.coli and S. enteritidis), and this effect was made more significant by UV light conditions. Samsi et al. (2019) first reported the use of gelatin-chitosan films in the preservation of cherry tomatoes and grapes. The addition of chitosan increased mechanically, specifically with respect to transparency, vapor, and water permeability. In addition, the antimicrobial properties of these films were similar to those of the commercial cling films.

1.5 Bionanocomposites

An alternative for the improvement of the properties of biodegradable biopolymers is the development of nanocomposites with the use of nanopar...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- List of Abbreviations

- List of Symbols

- Preface

- Editors

- Contributors

- CHAPTER 1. An Overview of Biopolymers from Natural Resources

- CHAPTER 2. Fabrication of Bionanocomposites from Chitin

- CHAPTER 3. Fabrication of Biocomposites from Chitosan: Preparation to Applications

- CHAPTER 4. Thermal and Mechanical Studies for Chitin and Chitosan Bionanocomposites

- CHAPTER 5. Barrier, Degradation, and Cytotoxicity Studies for Chitin-Chitosan Bionanocomposites

- CHAPTER 6. Chitin- and Chitosan-Based Bionanocomposites for Active Packaging

- CHAPTER 7. A Theoretical Approach to Chitin- and Chitosan-Based Bionanocomposites

- CHAPTER 8. Novel Approaches for Chitin/Chitosan Composites in the Packaging Industry

- Index