Friction and Wear of Ceramics

Principles and Case Studies

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Friction and Wear of Ceramics

Principles and Case Studies

About this book

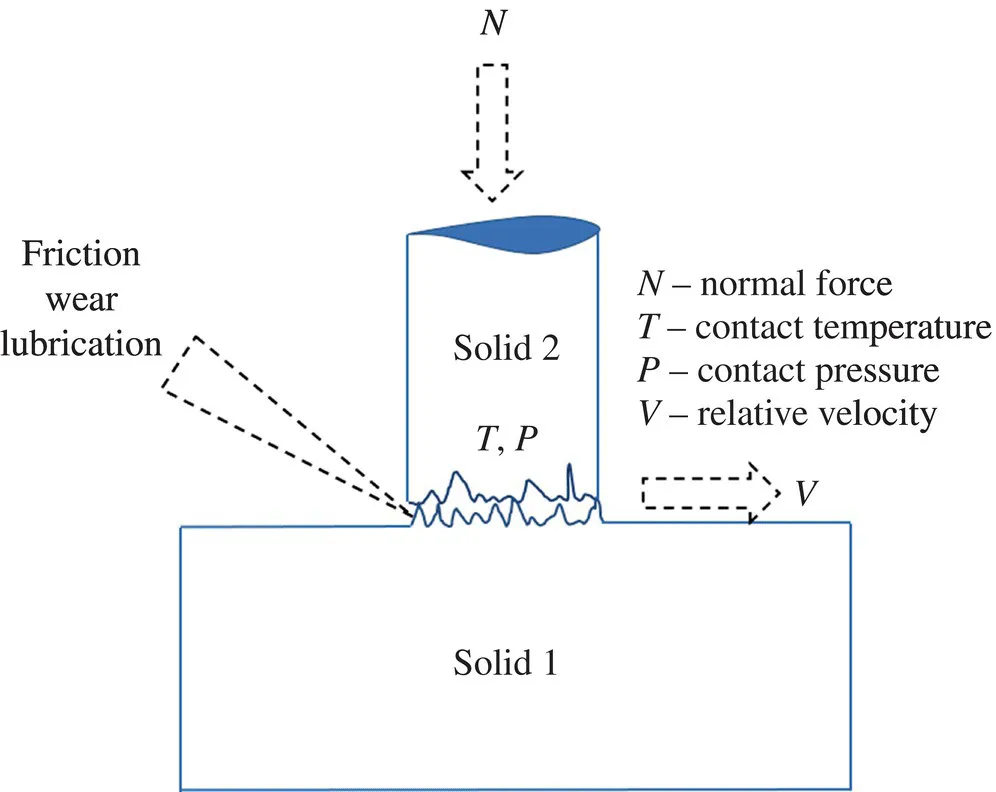

This book covers the area of tribology broadly, providing important introductory chapters to fundamentals, processing, and applications of tribology. The book is designed primarily for easy and cohesive understanding for students and practicing scientists pursuing the area of tribology with focus on materials. This book helps students and practicing scientists alike understand that a comprehensive knowledge about the friction and wear properties of advanced materials is essential to further design and development of new materials.

The description of the wear micromechanisms of various materials will provide a strong background to the readers as how to design and develop new tribological materials. This book also places importance on the development of new ceramic composites in the context of tribological applications.

Some of the key features of the book include: Fundamentals section highlights the salient issues of ceramic processing and mechanical properties of important oxide and non-oxide ceramic systems; State of the art research findings on important ceramic composites are included and an understanding on the behavior of silicon carbide (SiC) based ceramic composites in dry sliding wear conditions is presented as a case study; Erosion wear behavior of ceramics, in which case studies on high temperature erosion behavior of SiC based composites and zirconium diboride (ZrB2) based composites is also covered; Wear behavior of ceramic coatings is rarely discussed in any tribology related books therefore a case study explaining the abrasion wear behavior of WC-Co coating is provided. Finally an appendix chapter is included in which a collection of several types of questions including multiple choice, short answer and long answer are provided.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Section I

Fundamentals of Ceramics: Processing and Properties

1

Introduction: Ceramics and Tribology

1.1 Introduction

Table of contents

- Cover

- Table of Contents

- About the Authors

- Foreword by Dr. Sanak Mishra

- Foreword by Prof. Koji Kato

- Preface: The Most Influential Science that Needs to Be Better Understood

- Section I: Fundamentals of Ceramics: Processing and Properties

- Section II: Fundamentals of Tribology

- Section III: Case Study: Sliding Wear of Ceramics

- Section IV: Case Study: Erosive Wear of Ceramics

- Section V: Case Study: Machining‐Induced Wear of Cermets

- Section VI: Future Scope

- Appendix: Appraisal

- Index

- End User License Agreement