- 296 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Laser Safety Management

About this book

An effective laser safety program can mean big savings in time, money, effort, and most importantly, human well-being. It can improve the quality of your research program, your organization's reputation, and ultimately, improve your bottom line. Based on the extensive experience of active Laser Safety Officer Kenneth Barat, Laser Safety Management provides practical tools for successfully implementing a laser safety program in any environment.

The book defines the three elements of laser safety: users, the laser safety officer, and incidental personnel. It covers the types of laser injuries, standard operating procedures to ensure safety, tips and tools to avoid pitfalls, training, control measures, and personal protection equipment. The author explores the laser safety officer position and delineates the required elements of effective SOPs. He also discusses non-beam hazards, includes practical control examples and sample forms, and covers U.S. and European regulations and standards.

Taking a pedagogical approach, the book covers not only how to avoid accidents, but how to investigate them if they do occur. It includes a sample safety program designed to evaluate your current safety plan and act as a roadmap for where you need to be and how to get there. Filled with common sense solutions for laser safety issues, the book makes setting up a safety program practically painless.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1 Overview

1.1 Traditional Laser Safety

The traditional way that laser safety has been addressed for decades is laid out in the American National Institute Standard for the Safe Use of Laser Z136.1. This can be found in the Hazard Evaluation and Classification section of the standard.

Several aspects of the application of a laser or laser system influence the total hazard evaluation and thereby influence the application of control measures:

- The laser or laser system’s capability of injuring personnel or interfering with task performance

- The environment in which the laser is issued

- The personnel who may use or be exposed to laser radiation

Preceding this hazard evaluation protocol is the appointment of a laser safety officer or advisor, who will be referred to in this text as the LSO. It is the LSO’s responsibility to see that laser safety is adequately addressed at a facility or institution.

1.2 Life Cycle

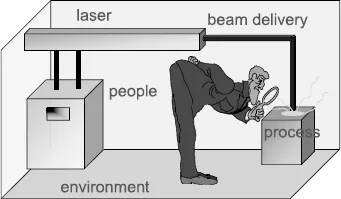

A more comprehensive evaluation approach is to expand this evaluation from three components to five and then add two life cycle phases: design and disposal. The five components are:

- The laser or laser system’s capability of injuring personnel

- The beam path of the laser system

- The interaction of the laser beam with its intended target

- The environment in which the laser is used

- The personnel who may use or be exposed to the laser radiation

1.2.1 THE Laser or LASER SYSTEM’S CAPABILITY OF INJURING PERSONNEL

Here are the factors of the laser source itself:

- What type of laser? Here one is interested in details such as whether it uses a pulsed or continuous wave (CW) and the nature of the wavelengths being generated, that is, ultraviolet, visible, near infrared, mid- or far infrared? Each of these will have some effect on the nature and level of control measures and hazard the laser posses to an individual.

FIGURE 1.1 Representation of complete hazard evaluation approach.

FIGURE 1.1 Representation of complete hazard evaluation approach. - What is the output of the laser? Are we talking about milliwatts, nanojoules, megawatts, or joules of output? These answers and the wavelength will have a dramatic effect on possible laser protective eyewear requirements.

- What is the classification of the laser? In the research and development (R&D) environment almost all lasers are class 3R(3A), 3B, or 4.

1.2.2 THE BEAM PATH OF THE LASER SYSTEM

You need to consider what happens to the laser beam once it leaves the laser source. In a very similar way you consider your commute from leaving the security of your garage to your work destination. Are you one of the lucky ones who has a minor commute of several minutes, or do you have a long arduous commute of highways, tunnels, and bridges?

In laser terms the beam path could be open, contained in fiber optics, or enclosed. In addition, just like the driver going down a steep grade, the beam could be amplified or go through nonlinear optics and therefore produce a change of lanes in our driving example, but for photons it is a change of wavelength. This could occur several times along with possible chirp stretching or compression. Any of these steps or a combination of them will affect the safety requirements one might apply to a system.

1.2.3 THE INTERACTION OF THE LASER BEAM WITH ITS INTENDED TARGET

Once the laser radiation reaches its destination, just like our driver reaching work, many options lie ahead, from that great day at work to violent meetings. A percentage of the beam may be reflected off a target, or beam interaction may generate gases as a result of products requiring ventilation. An intense pulse laser beam may generate ionizing radiation in the form of neutrons; gamma or x-rays even cause activation of products, hence generating additional ionizing radiation. Maybe the end of the beam path is delivered through a robotic arm, which introduces new concerns for evaluation.

1.2.4 THE ENVIRONMENT IN WHICH THE LASER IS USED

Now we have to consider factors from the workplace and how they contribute to our hazard evaluation. Do they make our job easier or harder? Places such as a clean room may do both. While adding to access control and thereby helping keep unauthorized persons out, cleanness requirements may make it harder to implement other controls. Other common laser use environments are the operating room, manufacturing floor, fabrication area, and our chief interest, the research laboratory.

1.2.5 THE PERSONNEL WHO MAY USE OR BE EXPOSED TO LASER RADIATION

When we think of these people, authorized laser users, ancillary staff, visitors, and in some case consumers come to mind. As each of these groups is evaluated, items such as training requirements, personnel protective equipment, and even ergonomic factors require consideration.

1.3 Additional Life Cycle Elements

1.3.1 DESIGN

The designing of safety into a laser product is a clear legal responsibility of the laser manufacturer, as called out in national product safety codes and regulations. Items such as protective housings, interlocks, labels, and electrical safety controls are all rather standard and expected by the purchaser of such products. The reader should check the Web site of the Center of Radiological Devices and Radiological Health for a listing of requirements and guidance documents. The design of a research setup is more a by-product of environmental or experimental need to reduce air turbulence or keep out unwanted light pollution than part of an overall safety plan. In some settings the laser beam path may travel across several optical tables and even across walkways or through a wall. Time given to providing a safe work environment will pay dividends to the user and those visiting the laser use area. Designers also need to think about what goes into the laser and related equipment and how to dispose of it.

1.3.2 DISPOSAL

Few laser safety professionals think about disposal of laser equipment until the issue is brought before them. Unlike radioactive material or radiation-generating products, there is little control over who buys laser products or how they are disposed of. This may be changing. Laser products can contain hazardous materials whose disposal can require special care. This is highlighted by the international effort to rid electronic and other products of hazardous materials, that is, the “greening of products.” Regulations that require this are Waste from Electrical and Electronic Equipment (WEEE) and Restriction of Hazardous Substances (RoHS). Both of these European norms and others push the concept of corporate social responsibility, which fits very well into the design and disposal phases of our approach.

Some of the common ways to dispose of laser equipment rather than sending it to landfills are:

- Donating the equipment to educational institutions

- Contacting resale firms

- Looking for a home for the equipment within one’s own organization

- Auctioning the equipment

- Returning it to the manufacturer (Some manufacturers do have limited return for disposal programs).

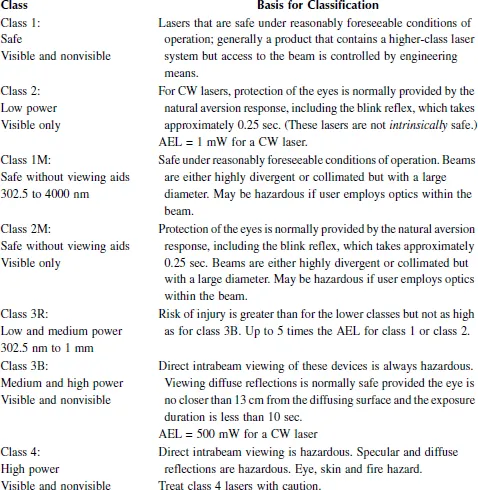

1.4 Classification

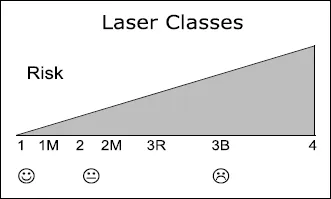

Laser hazard classification gives the user or laser safety officer an initial sense of the hazard the laser system or product presents to the user and others in the area. Rather than using colors to alert one to the fire hazard level in laser safety, a numerical code is used. The higher the number, the greater the hazard potential. Potential is the key word, for any laser system can be made safe. The hazard levels range from class 1, no hazard, to class 4, maximum potential hazard (Table 1.1). ANSI, the International Electrotechnical Commission (IEC), and the Center for Devices and Radiological Health (CDRH) each had slightly different classification systems until 2005, when they all adopted a uniform approach.

A key component of laser safety is the hazard classification scheme (Figure 1.2), which is an indication of the laser’s capability of injuring personnel. All laser or laser systems are classified according to their accessible radiation during operation, which in a research setting can be different from the classification of the laser source. Thus, a class 3B laser beam can be amplified on an optical table to class 4. Likewise, a class 3B or 4 laser beam can be attenuated to a lower classification as part of an optical set up. Laser products sold in the United States are usually classified in accordance with the Federal Laser Product Performance Standard, which falls under the Food and Drug Administration (FDA), CDRH. Those sold in Europe are classified to meet IEC 60825-1. Be aware that under CDRH Laser Notice 50, laser products sold in the United States can also be labeled with a certification as meeting IEC 60825-1. If the laser has been modified subsequent to classification by the manufacturer, its falls upon the LSO to classify the new laser system or product.

Lasers are classified according to their potential to cause biological damage. The pertinent parameters are laser output energy or power, radiation wavelengths, exposure duration, and cross-sectional area of the laser beam at the point of interest. In addition to these general parameters, lasers are classified in accordance with the accessible emission limit (AEL), which is the maximum accessible level of laser radiation permitted within a particular laser class.

Table 1.1 Laser Hazard Classification

FIGURE 1.2 Risk vs. hazard classification.

In laser safety standards and regulations, laser hazard classifications are used to signify the level of hazard inherent in a laser system and the extent of safety controls required. These range from class 1 lasers (which are inherently safe for direct beam viewing under most conditions) to class 4 lasers (which require the most strict controls). The laser classifications are described as follows:

1.4.1 TIME BASE FOR CLASSIFICATION

Different time bases are used for the different classes and wavelength ranges as follows:

- 0.25 s for class 2, class 2M, and class 3R in the ...

Table of contents

- Cover Page

- Title Page

- Copyright Page

- Contents

- Chapter 1 Overview

- Chapter 2 Biological Effects: Why We Care About Laser Exposure

- Chapter 3 The Laser Safety Officer: The Key to Laser Safety

- Chapter 4 Standard Operating Procedures: A Binding Safety Contract

- Chapter 5 Practical Tools for Laser Safety and Traps to Avoid

- Chapter 6 The Laser-Safety Management Program

- Chapter 7 Laser Safety Training

- Chapter 8 Personnel Protection Equipment

- Chapter 9 Laser Accidents

- Chapter 10 An Explanation of Control Measures

- Chapter 11 U.S. and European Regulations and Standards

- Chapter 12 Laser Safety Calculations

- Chapter 13 Nonbeam Hazards

- Chapter 14 Practical Control Measures

- Chapter 15 Laser Basics

- Glossary

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Laser Safety Management by Ken Barat in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Electrical Engineering & Telecommunications. We have over one million books available in our catalogue for you to explore.