- 256 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Design for Reliability

About this book

Today's marketplace demands product reliability. At the same time, it places ever-increasing demands on products that push the limits of their performance and their functional life, and it does so with the expectation of lower per-unit product costs. To meet these demands, product design now requires a focused, streamlined, concurrent engineering process that will produce a product at the lowest possible cost in the least amount of time.

Design for Reliability provides a systematic approach to the design process that is sharply focused on reliability and firmly based on the physics of failure. It imparts an understanding of how, why, and when to use the wide variety of reliability engineering tools available and offers fundamental insight into the total design cycle. Applicable from the idea phase of the product development cycle through product obsolescence, Design for Reliability (DfR) concepts integrated with reliability verification and analytical physics form a coherent stage gate/phase design process that helps ensure that a product will meet customers' reliability objectives.

Whether you are a high-volume manufacturer of consumer items or a low volume producer of military commodities, your goal is the same: to bring a product to market using a process focused on designing out or mitigating potential failure modes prior to production release. Readers of Design for Reliability will learn to meet that goal and move beyond solidifying a basic offering to the marketplace to creating a true competitive advantage.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

CHAPTER 1

Reliability Science

1.1 Introduction

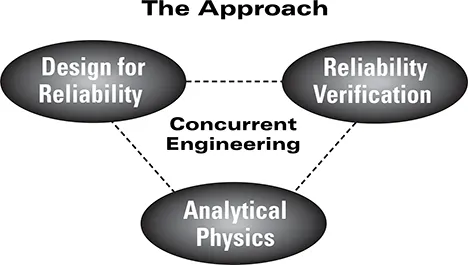

Today’s marketplace demands reliability. Meeting that challenge requires developing a reliability engineering team that supports the full design-development process. The reliability team performs three fundamental activities as shown in Figure 1.1: Design for Reliability, Reliability Verification, and Analytical Physics. These activities are the building blocks to a sound reliability program that sits on a foundation of concurrent engineering.

The first reliability science activity in support of product development is Design for Reliability (DfR). This starts in the Idea Phase of the product development cycle and continues through product obsolescence. Design for Reliability is used to affect the design for a positive product reliability improvement by utilizing physics-of-failure knowledge to design out potential problems. This process is interrelated with the two other building block activities, forming a coherent stage gate/phase design process.

The second activity is Reliability Verification. Here, verification studies and demonstration tests ensure meeting customers’ reliability objectives. Reliability Verification takes place in two main forms: Process Reliability and Design Maturity Testing. Process Reliability focuses on the development of a fundamental understanding of a platform’s inherent reliability and provides the foundation to develop a realistic accelerated design maturity test. Design Maturity Testing demonstrates that a product’s failure rate and a customer’s needs will be met when the product is exposed to demanding conditions. The third activity, Analytical Physics, is designed to collect knowledge about a product’s physics-of-failure. Understanding the nature of how and why a product can fail is the key to designing and building a product that will meet our customers’ expectations.

Figure 1.1 The product development building blocks

1.2 Reliability Design: “A Stage Gate Approach”

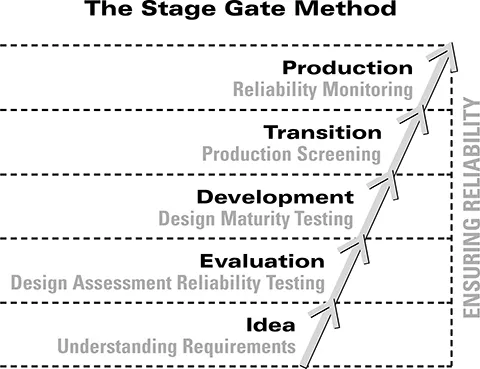

Reliability engineering with its three major activities supports a phased product development cycle called stage gate. The stage gate method is shown in Figure 1.2. The stage gate effort underpins product development, starting with product conception and continuing through final product obsolescence, including post-production. The stage gate method is essential in designing a reliable product capable of meeting customers’ expectations. Ensuring that designs will meet customers’ needs starts with an understanding of the full design requirements, environments hazardous to full product operating life, potential product use and misuse, total product cost goals, and reliability service life needs.

1.2.1 The Idea Phase

Stage gate 1: The concurrent engineering process of DfR activities begins with understanding customer requirements. Often these activities include the tools of Failure Modes and Effects Analysis (FMEA), product competitive benchmarking, and the reliability predictive modeling used to direct the design approach. The process actually starts in the Idea Phase stage and continues through the full product development cycle. These tools are deployed with the goal of reducing the risks associated with the first-pass success of a design’s launch into the market. The first real impact on reliability occurs in this stage, for it is in the Idea Phase where the first concept of a design solution is selected, defining the ultimate reliability level that can be achieved.

Figure 1.2 Stage gate process

1.2.2 The Evaluation Phase

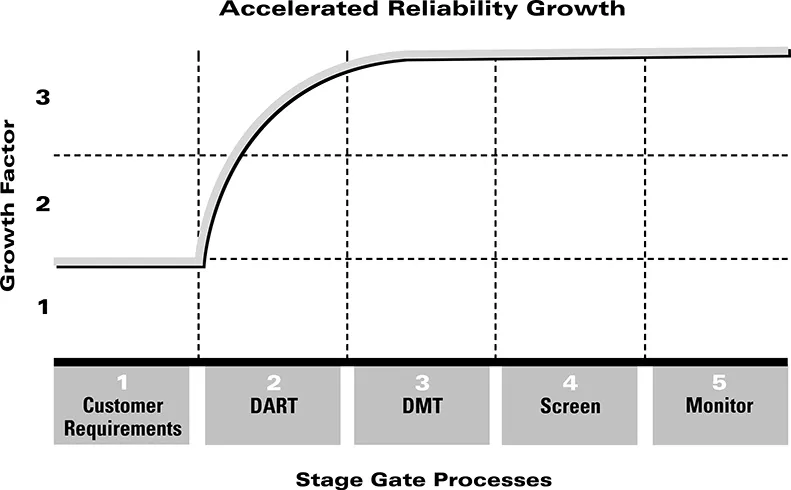

Stage gate 2: Design risk-mitigation activities will occur during the evaluation phase. Risk-mitigation studies are performed to resolve uncertainties around the design approach. These Design Assessment Reliability Test (DART) studies (see Chapter 3) are usually not statistically sampled, but can investigate potential fatal flaws present in a chosen design. Reliability growth is the major focus of the evaluation phase where normally a 65 percent improvement in reliability can be achieved from the initial design point (see Figure 1.3). This is accomplished usually through test-analyze-and-fix activities in design risk-mitigation studies.

1.2.3 The Development Phase

Stage gate 3: The primary function of reliability engineering in this phase occurs toward the end of the development process. Here, Design Maturity Testing (DMT) is used to demonstrate and validate that a design will meet the expected operating-life requirements identified in stage gate 1. Design Maturity Testing is based on performing a physics-of-failure approach, knowing and understanding the physical issues within the design, and demonstrating that those issues will not impact the product within its useful life environment. This is accomplished by performing statistically significant failure-free accelerated life testing. A physics-of-failure approach is used in developing the Design Maturity Test. Tests in this phase are based on reliability science, historical information, process physics-of-failure studies, environmental product limits, and product environmental objectives. Typically, the statistically significant tests ensure that the product will meet its reliability objective at a 90 percent confidence level.

Figure 1.3 Growth reliability in stages

Table 1.1 Stage gate reliability

Phase | Stage Gate | Task | Description |

1 | Idea | Understanding Customer Requirements | Concurrent engineering approach tools such as Failure Modes and Effects Analysis (FMEA) and competitive benchmarking are deployed to define the true design requirements. |

2 | Evaluation | Design Assessment Reliability Testing | Risk-mitigation studies and reliability growth efforts focus on finding and fixing failure modes in real time, concurrent with the design process, using the techniques of highly accelerated reliability growth, highly accelerated life testing (HALT) with Test-Analyze-and-Fix (TAAF), and others as necessary for the technology. |

3 | Development | Design Maturity Testing | Demonstrate that a design is reliably meeting the customer’s expectations. Perform statistically significant accelerated tests, usually failure-free. |

4 | Transition | Production Screening | Ensure early production units are robust. Check for infant mortality problems. |

5 | Production | Reliability Monitoring | Ensure continual product reliability and quality to design obsolescence. |

1.2.4 The Transition Phase

Stage gate 4: A reduction in reliability activities starts at this stage. The primary function of reliability engineering at this point is to help define the proper screening to prevent infant mortality failures from escaping to the customer. Defining the proper level of screening is not always simple. Failure mechanisms must be found. The correct screening technique to excite failure mechanisms must be identified and employed at the right level and duration to detect flaws without removing useful product life or inducing latent failures.

1.2.5 The Production Phase

Stage gate 5: The reliability engineering activities at this point are limited to defining the proper reliability monitoring process and techniques to ensure that the design continues to deliver the same performance over its lifetime. Reliability monitoring ensures process variations of the production cycle do not affect product reliability.

1.2.6 Defining How Much Is Enough

Reliability engineering engaged early in the design cycle and supporting the design to product obsolescence ensures a successful design release. Determining the level of reliability effort associated with product development, an assessment of the project’s risk level is necessary. Often a design may be a spinoff of an existing design or a slight modification of a proven design. These products would not automatically dictate a full stage gate design process, using all the tools of reliability engineering. If a product is based on new technology and is revolutionary in nature, a high-level stage gate effort is to be performed. Because financial risk is linked to technology, it, too, is factored into an assessment. A balance and selection of these tools are needed to ensure that the highest levels of reliability are achieved, but not at a cost level that makes them prohibitive to the marketplace. The concept of risk is fully explored in Chapter 13. Table 1.1 describes the nature of the task associated with each phase of the design process.

1.3 Design for Reliability Tools

Designing a reliable product today is truly a concurrent engineering process. All design disciplines must be part of the product’s development to ensure a robust design that meets a customer’s needs. A reliability engineering approach with its series of tools can focus the design process. An overview of tools described here is shown in Figure 1.4.

The first major tool to be used is Failure Modes and Effects Analysis (FMEA)/Benchmarking. This is an important tool to ensure that reliability is integrated with product design (see Chapter 12). The FMEA tool can identify both specified and unspecified customer requirements for a design, how failure may occur, th...

Table of contents

- Cover Page

- Half title

- title

- copy

- preface

- ack

- fmchapter

- glossary

- Preface

- Section I: The Stage Gate Process

- 1 Reliability Science

- 2 Understanding Customer Requirements

- 3 Design Assessment Reliability Testing

- 4 Design Maturity Testing (DMT)

- 5 Screening and Monitoring

- Section II: Supporting Stage Gate

- 6 Semiconductor Process Reliability

- 7 Analytical Physics

- Section III: Topics in Reliability

- 8 Reliability Statistics Simplified

- 9 Concepts in Accelerated Testing

- 10 Accelerated Reliability Growth

- 11 Reliability Predictive Modeling

- 12 Failure Modes and Effects Analysis

- 13 Evaluating Product Risks

- 14 Thermodynamic Reliability Engineering

- Subject Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Design for Reliability by Dana Crowe, Alec Feinberg, Dana Crowe,Alec Feinberg in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Electrical Engineering & Telecommunications. We have over one million books available in our catalogue for you to explore.