eBook - ePub

Testing Tribocorrosion of Passivating Materials Supporting Research and Industrial Innovation

A Handbook

- 216 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Testing Tribocorrosion of Passivating Materials Supporting Research and Industrial Innovation

A Handbook

About this book

This first edition of Testing Tribocorrosion of Passivating Materials Supporting Research and Industrial Innovation: A Handbook treats in a clear, concise, and practical manner an important material degradation and protection matter. It is designed as a handbook and provides a well structured approach of the basics needed to investigate the tribocorrosion behavior of passivating materials, and to conduct in a correct way a laboratory investigation on it. It provides answers on practical and theoretical approaches of tribocorrosion phenomena to engineers and medical persons involved with material assemblies subjected to aggressive environmental and mechanical conditions. For academic researchers it is a pertinent tool assisting them in how they can perform a tribocorrosion investigation and obtain results that are correctly interpreted and can be exchanged. Different parts of the book are illustrated with practical examples. This handbook is truly an indispensable guide for every professional who comes into contact with the complex material degradation and protection processes that take place under combined corrosion and wear conditions. Fields of interest include: transportation (aeronautics, maritime, rail, automotive), medical implants (orthopaedics, dentistry), biochemistry, food production, energy production, and machining. The coordination of this handbook writing was done by Professor Jean-Pierre Celis (Katholieke Universiteit Leuven, Belgium) and Professor Pierre Ponthiaux (Ecole Centrale Paris, France) assisted by twelve European experts who contributed jointly to the nine chapters of this handbook. Main topics dealt with are tribocorrosion phenomena in medical and industrial sectors, depassivation and repassivation phenomena, impact on synergism in tribocorrosion, specific testing techniques, coupling tribology-to-corrosion, design of a testing protocol, and normalisation.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Testing Tribocorrosion of Passivating Materials Supporting Research and Industrial Innovation by Jean-Pierre Celis in PDF and/or ePUB format, as well as other popular books in Tecnología e ingeniería & Ciencias de los materiales. We have over one million books available in our catalogue for you to explore.

Information

1

Phenomena of tribocorrosion in medical and industrial sectors

Articulating systems are complex mechanical systems operating under a combination of sliding, rotation, slip, vibrations, weight bearing, and loading conditions. For example, in hip or knee joints and dental prostheses, the working parameters largely affect the lifetime of such contacting material systems. Articulating systems are present in engineering systems ranging from large scale ones such as in transportation, robotica, or offshore installations, down to small sized ones such as in microelectromechanical systems (MEMs). A commonly experienced problem in medical prostheses and in mechanical systems is the synergism between corrosion and wear occurring under field operation causing an enhanced material degradation. Achieving better performing articulating systems in clinical and engineering sectors is a real challenge in this early 21st century. In this chapter, an overview is given of the main parameters affecting tribocorrosion in medical and industrial systems, and this is illustrated with a few case studies.

1.1 Tribocorrosion: concept and definition

Corrosion and wear are two modes of degradation of materials which are well known and widely studied. While basic mechanisms of corrosion have been clearly identified, despite progress over the past 30 years by tribologists, fundamental processes responsible for friction and wear have not been fully identified and understood. Several fundamental questions remain unanswered today. Indeed, if the electrochemist is now able to describe the liquid/solid interface and knows how to calculate the dissolution of a metal immersed in a corrosive liquid, the tribologist still poorly understands the physical origin of friction and the elementary processes of wear. A better understanding of these fundamental phenomena may be made by theoretical physics (molecular dynamics) and nanotribology [1–4].

Given what has been said in Chapter 0, the study of material degradation by processes that involve corrosion and wear, is a difficult task. No serious fundamental approach can be attempted today with the tools and knowledge available. But given the importance of tribocorrosion in many applications, there is a strong need to develop specific models and devices to simulate and study phenomena involving wear and corrosion at the same time.

During tribocorrosion, the synergy between mechanical wear and (electro)chemical corrosion results in a total volume of removed material Wt which can differ from the sum of material removed separately by wear or corrosion. The volume Wt is given as a function of three components:

1.1 |

where Wm and Wc are the volume of material removed separately by the effects of wear and corrosion, respectively, and Ws represents the synergistic effect between wear and corrosion which can account for 20–70% of the total volume of material removed [5–8].

Equation 1.1 may also be written as follows:

1.2 |

with Wcm the effect of corrosion on wear, and Wmc the effect of wear on corrosion.

1.2 Main parameters affecting tribocorrosion

1.2.1 Techniques and set-up for tribocorrosion studies

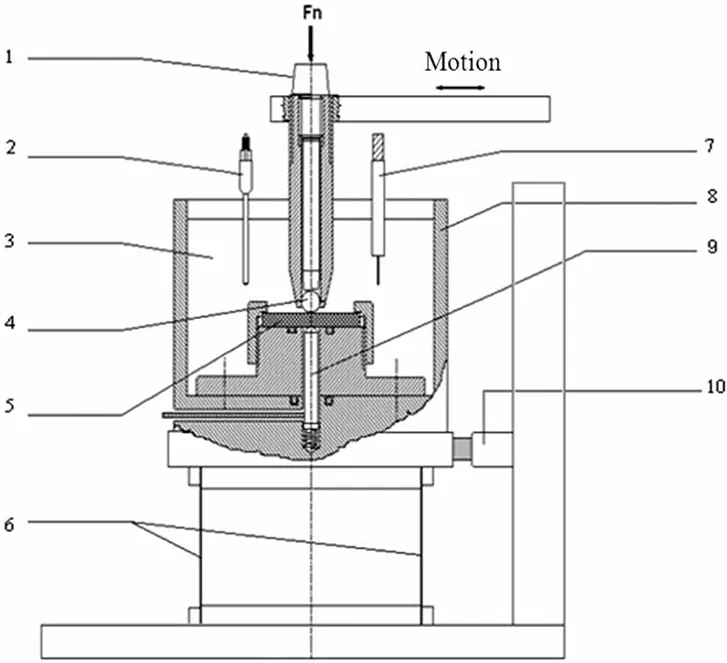

Tribocorrosion studies can be conducted by coupling electrochemical methods to tribology testing. A typical set-up for tribocorrosion testing is shown in Figure 1.1 [9]. It consists of a polytetrafluoroethylene (PTFE) cell mounted on a ball-on-disc tribometer called a tribo-electrochemical cell. A loaded ceramic ball (the counter-body) slides against the specimen (the working electrode) while the tangential force is measured with a force sensor. The electrochemical potential of the specimen is controlled with respect to a reference electrode which can be a platinum wire.

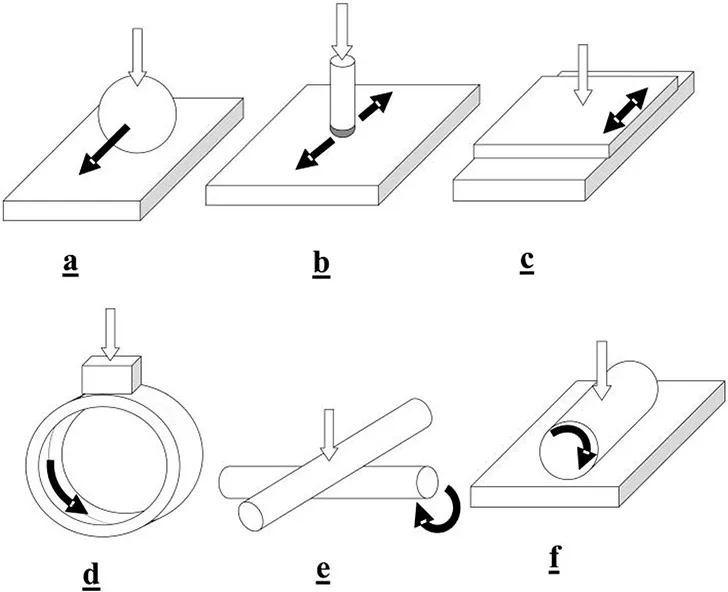

Depending on the particular application, tests can be conducted using a number of different contact geometries (Figure 1.2).

1.2.2 Materials and environment

The degradation mechanisms of a material subjected to friction in a corrosive environment involve chemical and mechanical effects, known for a long time as the Rehbinder effect. Indeed, the surrounding environment (air, gas or liquid) interacts with a material surface, affects greatly the surface composition, and thus can consequently affect the tribocorrosion process.

Environment, mechanical properties, chemical composition and microstructure are the most important parameters that determine the material behaviour in the case of tribocorrosion. Under tribocorrosion conditions, the interaction between the surface of a material and the electrolyte may lead to the formation of a new compound whose properties differ from those of the bare material. This may lead to an enhanced or decreased surface resistance to friction, wear, and corrosion.

During friction, a third body whose formation and evolution depend strongly on contact stiffness and geometry in addition to vibrations [10], plays a crucial role in friction and wear. Wear debris may agglomerate to form a lubricating and a protective film or to act as abrasive particles [11, 12].

It is known in tribology that the microstructure of materials has to be carefully chosen. In the case of steels, phases such as ferrite, austenite and pearlite are relatively soft with a hardness ranging from 100 to 300 HV, and offer little resistance to wear. Hard phases such as martensite and bainite with a hardness ranging from 800 to 1000 HV are particularly well-suited when the surface is subjected to abrasive wear [13, 14]. In addition, the mechanical characteristics of steels can be greatly improved by the addition of chromium, molybdenum, vanadium, manganese and nickel. When added in small quantities (1–4%), these elements yield a finer microstructure and give the material greater hardness and wear resistance [14].

1.1

Tribocorrosion set-up: 1, normal load (Fn); 2, reference electrode; 3, electrolyte; 4, counterbody; 5, sample as working electrode; 6, spring plates; 7, counter electrode; 8, electrochemical cell; 9, connection of sample to potentiostat; 10, tangential force sensor (adapted from Ref. 9)

In tribocorrosion, things are more complicated since chemical reactions which take place at the interface between metal and electrolyte modify the composition, and consequently, the properties of the surface. Indeed, the surface of a hard material may oxidise and form brittle or soft phases as in the case of 34CrNiMo6 steel, titanium or tungsten. On the other hand, hydrogen embrittlement of some materials may take place, for example, in the case of iron and many types of hardened steels. Hydrogen reduction at the surface may also lead to the formation of brittle hydrides as in the case of titanium and zirconium [15].

1.3 Examples of tribocorrosion in medical applications

When orthopaedic or dental implants are placed in the body and submitted to friction, they may suffer tribocorrosion due to the simultaneous action of corrosion by the body liquid and mechanical wear. This short overview is not intended as a state-of-the-art and interested readers are suggested to consult specialised open literature on biomaterials and their applications.

1.2

Some contact geometries used in tribocorrosion studies: a) ball-on-flat; b) pin-on-disc; c) flat-on-flat; d) flat-on-cylinder; e) cylinder-on-cylinder; f) cylinder-on-flat

1.3.1 Biomaterials, biocompatibility

Biomaterials are natural or synthetic materials used in medical devices to perform, restore, or replace the natural functions of living tissues or organs in the animal or human body. The materials must be biocompatible which means that they will not be rejected by the body and will not cause any infection. Due to their high passivity and biocompatibility, 316L stainless steel, titanium and CoCrMo alloys are the metals most used for medical implants (e.g. hip, knee, and tooth). Numerous polymers such as ultra-high molecular weight polyethylene (UHMWPE) or ceramics such as alumina or zirconia, are also widely used as biomaterials.

One of the most important issues in the use of metallic biomate...

Table of contents

- Cover Page

- Title Page

- Copyright Page

- Contents

- Series introduction

- Volumes in the EFC series

- List of Symbols

- 0 Introduction

- 1 Phenomena of tribocorrosion in medical and industrial sectors

- 2 Depassivation and repassivation phenomena: synergism in tribocorrosion

- 3 Specific testing techniques in tribology: laboratory techniques for evaluating friction, wear, and lubrication

- 4 Specific testing techniques in tribology and corrosion: Electrochemical techniques for studying tribocorrosion processes in situ

- 5 Design of a tribocorrosion experiment on passivating surfaces: Modelling the coupling of tribology and corrosion

- 6 Towards a standard test for the determination of synergism in tribocorrosion: Design of a protocol for passivating materials

- 7 Towards a standard test for the determination of synergism in tribocorrosion: Detailed testing procedure for passivating materials

- 8 Normative approach

- Index