- 568 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Provides a thorough review of properties, durability and use of high performance concrete, derived from recent research and experience. This book contains contributions from the leading French, Canadian and Swiss researchers, designers and material specialists, translated into English for the first time.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Topic

ArchitetturaPART ONE

KNOWLEDGE OF THE MATERIAL

1 MICROSTRUCTURE OF HIGH PERFORMANCE CONCRETE

ENS de Cachan, France

1 Introduction

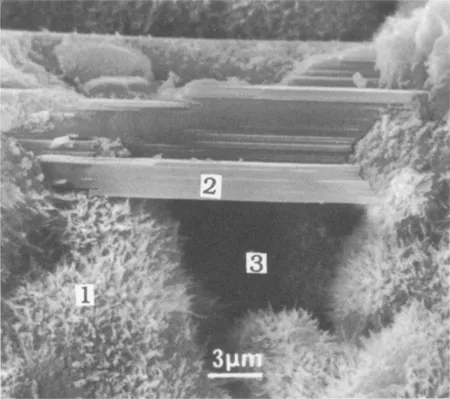

Hardened concretes have mechanical characteristics lower than those of steel or alumina. The highest differences appear in the flexure strength and toughness (1). A Portland cement concrete is a porous and heterogeneous material. The matrix which embeds sand grains and aggregates is constituted by different hydrates. The most important of them are hydrated silicates C – S – H which can appear as fibers and Ca (OH)2 which crystallises in massive superimposed hexagonal plates (Fig. 1). The total porosity of a Portland cement paste is between 25 and 30 % by volume for a cement / water ratio of 0.5. This porosity is decomposed into two types of cavities (i) C – S – H pores of several nanometer size (ii) capillary pores between hydrates, air bulles, cracks : their size is between 100 nm and several mm.

The low mechanical performances of concrete have been attributed to the capillary porosity and excess of water needed for the workability of fresh concrete. An improvement has been obtained by several processes which reduce the porosity (impregnation, pressure) and the water / cement ratio (use of superplasticizers). New products also appeared. They were MDF, Macro Defect Free cement and DSP, Densified System containing homogeneously arranged ultrafine Particules (2). The first one contains a polymer, the second silica fume.

2 High performances cement pastes

Filling in capillary pores or extracting the excess of water by pressure or reducing the water / cement ratio with superplasticizers are processes which densify the cement paste which therefore appears more homogeneous and more amorphous than the normal Portland cement paste.

Figure 1: Portland cement paste, w/c = 0.5, (1) Fibrous C-S-H, (2) Ca(OH)2, (3) capillary pore.

2.1. Cement paste with a low water / cement ratio

In 1897, Féret (3) gave an expression of the compressive strength as follows :

(1) |

with c, w, a respectively the volume of cement, water and air. After this formula reducing the water/cement ratio leads to an increase in strength. However there is a limit of the water/cement ratio related to the workability of the fresh concrete.

2.1.1 Superplasticizers

Superplasticizers like naphtalene sulfonate, melamine, lignosufonate used for dispersing solid particles also involve a reduction of the water/cement ratio down to w/c = 0.16 (4). Studies with the proton nuclear magnetic resonance showed that the superplasticizer was adsorbed on the solid particles and formed a pellicle in which the water molecules were still mobile (4,6). To the pellicular effect is added the dispersion of solid particles. Both improve the rheology of the suspension. Compressive strengths as high as 200 MPa were achieved in that way. Porosity was about 5 % by volume and the matrix occurred homogeneous and like amorphous.

2.1.2 Pressure and vibration

Compressive strengths of 644 MPa were measured under pressure at high temperature (1020 MPa, 150°C). The total porosity was therefore 2 % in volume (7). Hydrates were identified as gels. The degree of cement hydration was 30 %. Silicates C – S – H embedding anhydrous cement grains behaved like a glue between dense particles. Both hydrates and clinker simultaneously contributed to the high strength of the hardened cement paste. The vibration eliminated air bubbles created during mixing which could behave as Griffith defects in the flexure tests.

2.2. Ultrafine particles DSP

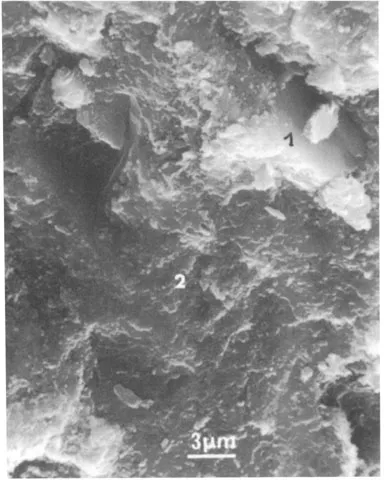

DSP (4) contain Portland cement, silica fume and superplasticizer. Silica fume occurs as microspheres of 0.5 urn average size which fill in interstitial spaces between cement grains of 30 – 100 um size. First silica fume plays a physical role of filler. All solid particles are well dispersed by the superplasticizer and there is no bleeding. During the cement hydration, silica fume spheres are sites of nucléation (8) for cement hydrates and then react as a pozzolanic material giving an homogeneous and like amorphous C – S – H (Fig. 2).

Figure 2: DSP with silica fume, (1) Ca(OH)2, (2) amorphous C-S-H.

2.3. Cement MDF

The densification of the cement paste increases compressive strength. However the material still exhibits a low flexure strength.

A new approach of the porosity was done by Kendall, Howard and Birchall (9) who considered two pore families :

Pores of volume p : capillary pores

Pores of length 2c : cracks.

Applying the Griffith theory of the fracture mechanics, the criterion for crack extension becomes :

with

E0 = Young modulus

R0 = fracture energy for p = 0

2c = crack length.

So there appears two possibilities for increasing strengths: either reduce capillary porosity or reduce crack length. This second way could increase the flexure strength when 2c < 1 mm. This approach leads to the MDF, Macro Defect Free cement (1).

In MDF a water soluble polymer (hydroxypropylmethyl cellulose or hydrolised polyvinylacetate) disperses and lubricates cement grains in the cement paste suspension. The polymer being able to form a rigid setting gel, a strong mixing is necessary. During setting and hardening, the polymer dihydrates while cement hydrates. In the hardened material the polymer is highly bound to cement grains and the final porostiy is about 1 % by volume.

A macro defect free cement is composed of 100 parts of cement (in weight), 7 parts of polymer and 10 parts of water.

The microstructure is close to that of cements with a low water / cement ratio. The main characteristic is a dense and amorphous matrix around clinker grains. Ca (OH)2 crystals are in thin lamellae distributed in the cement paste contrary to the large and thick plates in a Portland cement paste (Fig. 3).

The limited space for the formation of large crystals avoids the appearance of cracks along the cleavage planes of superimposed plates. Flexure stre...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Contributors

- Foreword

- Introduction

- PART ONE KNOWLEDGE OF THE MATERIAL

- PART TWO DURABILITY

- PART THREE CONSTRUCTION

- Author index

- Subject Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access High Performance Concrete by Y. Malier in PDF and/or ePUB format, as well as other popular books in Architettura & Metodi e materiali in architettura. We have over one million books available in our catalogue for you to explore.