- 378 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

The Behavior of Sandwich Structures of Isotropic and Composite Materials

About this book

The Behavior of Sandwich Structures of Isotropic and Composite Materials presents the mathematics, descriptions, and analytical techniques in the growing field of sandwich structures. From a background in sandwich structures to thermoelastic problems of sandwich structures and sandwich shell theory, the book provides the knowledge needed to analyze, design, and optimize various sandwich structures.

As one would expect from a book on sandwich structures, this volume discusses special failure modes such as face wrinkling and core shear instability. Coverage includes not only honeycomb cores, but also foam, web, and truss cores. An important topic in composite structure design, optimization is explored in two chapters on sandwich plates and sandwich shells. The author presents the optimization techniques in closed form and the methods are applicable to material selection and geometric design. The book also contains a set of problems and references at the end of each chapter. This text is ideal for engineers-in-training, as well as practical engineers who desire a comprehensive understanding of sandwich structures technology.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access The Behavior of Sandwich Structures of Isotropic and Composite Materials by JackR. Vinson in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Materials Science. We have over one million books available in our catalogue for you to explore.

Information

CHAPTER 1

Sandwich Structures: Origins, Advantages, and Uses

1.1 DESCRIPTION OF VARIOUS SANDWICH CONSTRUCTIONS

Everyone is familiar with a sandwich, because most of us grew up and continue eating them. Usually the faces are identical (as in two slices of store-bought and cut bread), but they can differ (analogous to a Kaiser roll). The inside (core) of a sandwich can include almost anything and can vary in thickness, density, and solidity. Occasionally, one can encounter a doubledecker sandwich as well, as in many box materials used for shipping.

Structural sandwiches follow suit, as shown in Figure 1.1; most often there are two faces, identical in material and thickness, which primarily resist the in-plane and lateral (bending) loads. However, in special cases the faces may differ in either thickness or material or both, because perhaps one face is the primary load-carrying, low-temperature portion while the other face must withstand an elevated temperature, corrosive environment, etc. Assuming a uniform core, the former sandwich is regarded as a symmetric sandwich, the latter an asymmetric sandwich.

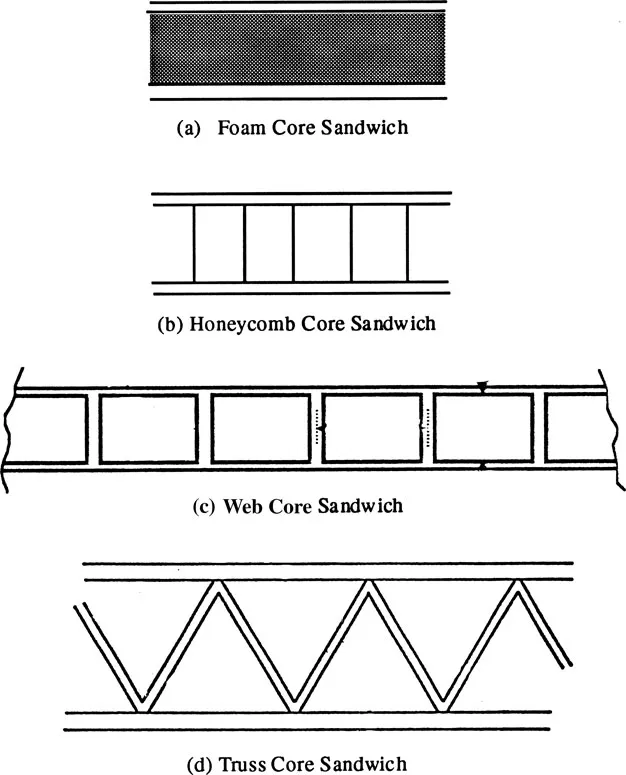

FIGURE 1.1. Types of sandwich construction.

The core of a sandwich structure can be almost any material or architecture, but in general, cores fall into four types, as shown in Figure 1.1: (a) foam or solid core, (b) honeycomb core, (c) web core, and (d) a corrugated or truss core. Developments in new cores continue to be of primary interest, such as new cores developed by Christensen [1] and Czaplicki [2]. Czaplicki has introduced a cellular core structure formed by progressive corrugation of a single continuous sheet of material. Bitzer [3] recently described several new honeycomb cores: thermoplastic CECORE, Marine Nomex, Korex, and non-metallic Tube-core.

Foam or solid cores are relatively inexpensive and can consist of balsa wood, and an almost infinite selection of foam/plastic materials with a wide variety of densities and shear moduli. Since World War II, honeycomb-core architectures have been widely used. The two most common types are the hexagonally-shaped cell structure (hexcell) and the square cell (egg-crate); see Figure 1.1(b). Web core construction is also used; see Figure 1.1(c), analogous to a group of I-beams with their flanges welded together. Truss or triangulated core construction is shown in Figure 1.1(d). In the web core and truss core constructions, the space in the core could be used for liquid storage or as a heat exchanger.

In all cases the primary loading, both in-plane and bending, are carried by the faces, while the core resists transverse shear loads (analogous to the web of an I-beam), and keeps the faces in place. In most foam-core and honeycomb-core sandwiches one can assume that all of the in-plane and bending loads are carried by the faces only. However, in web-core and truss-core construction, a portion of the in-plane and bending loads are also carried by the core elements.

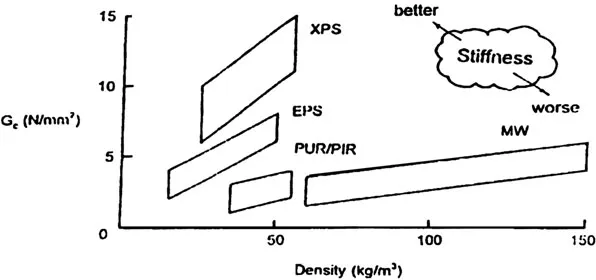

The following foam cores are discussed in more detail by Davies [4].

(1) Polyurethane (PUR), a thermosetting material; widely used

(2) Polyisocyanurate (PIR), a thermosetting material

(3) Phenolic foam (PF), a thermosetting material; not yet widely used

(4) Polystyrene (expanded, EPS and extruded, XPS), a thermoplastic material

These foam core materials can be compared by a plot of core shear modulus as a function of density as in Figure 1.2.

FIGURE 1.2. Shear stiffness of typical core materials as a function of density.

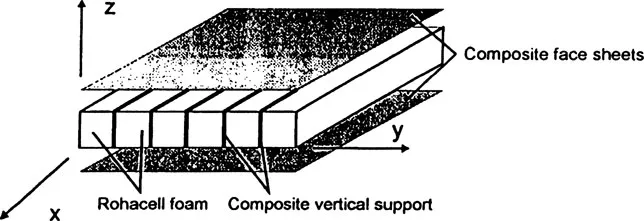

As stated earlier, in addition to the four types of core shown in Figure 1.1, there are or can be many other core architectures. For instance, Sun, Hasebe, and Hua [5] have studied sandwich panels with a core that is composite vertical laminate-reinforced Rohacell foam, as shown in Figure 1.3. Thus, one could say that this is a foam-filled web core; see Figure 1.1(c). With the type of core shown in Figure 1.3, as with the web core and truss core of Figure 1.1, the extensional and flexural stiffness of the sandwich in the flute direction is greater than the honeycomb and foam core of Figure 1.1(a) and (b), because the core resists more than a negligible part of the load.

FIGURE 1.3. Sandwich construction with laminate-reinforced foam core.

1.2 ADVANTAGES OF SANDWICH CONSTRUCTION OVER CONVENTIONAL MONOCOQUE THIN-WALLED CONSTRUCTION

Sandwich construction is playing an increasingly important role in structures because of its exceptionally high flexural stiffness-to-weight ratio compared to monocoque and other architectures. As a result, sandwich construction results in lower lateral deformations, higher buckling resistance, and higher natural frequencies than do other constructions. Thus, for a given set of mechanical and environmental loads, sandwich construction often results in a lower structural weight than do other configurations.

Even with these advantages, it is important and desirable to develop means by which to optimize the sandwich construction in order to: (1) determine the absolute minimum weight for a given structural geometry, loading, and material system; (2) rationally compare one type of sandwich construction with others; (3) rationally compare the best sandwich construction with alternative structural configurations (monocoque, rib-reinforced, etc.); (4) rationally select the best face and core materials to minimize structural weight; (5) select the best stacking sequence for faces composed of laminated composite materials; and (6) rationally compare the optimum construction weight to weights required when there are some restrictions; i.e., the weight penalty due to restrictions of cost, minimum gage, manufacturing, material availability, etc.

In the following discussion only, foam-core and honeycomb-core sandwich constructions will be covered. It is interesting, at the outset, to compare certain structural parameters of sandwich construction with those of monocoque construction of the same approximate weight. In general, foam and honeycomb cores do not carry any appreciable in-plane or bending loads to which the structure is subjected. Their primary purpose is to insure the spacing between the faces and to carry the transverse shear loads to which the structure is subjected. Also, generally, the core is a very small percentage of the sandwich weight.

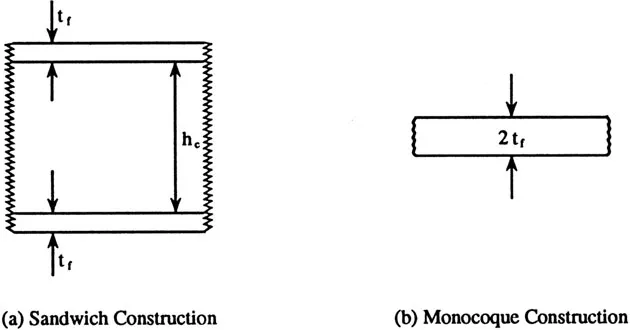

FIGURE 1.4. Cross section of sandwich and monocoque construction. (Reprinted from Reference [53].)

It is also interesting to compare an isotropic sandwich construction with a monocoque (thin-walled) construction of approximately the same weight. In Figure 1.4, the sandwich construction employs two identical faces of thickness tf, and a core depth of hc. The monocoque construction on the right is a flat sheet construction of thickness 2tf, hence approximately the same weight as the sandwich construction using the same face material.

For an isotropic face material with a modulus of elasticity, Ef, the extensional stiffness per unit width, K, for both the sandwich and the monocoque construction is

(1.1) |

Thus, for in-plane tensile and compressive (up to buckling) loads the two constructions have the same in-plane stiffness.

However, there is a marked difference in the flexural stiffness per unit width, D. For the panel construction of Figure 1.4(b) above, the flexural stiffness is

(1.2) |

while the flexural stiffness for the isotropic foam or honeycomb-sandwich construction is given by

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Dedication

- Table of Contents

- Preface

- Chapter 1. Sandwich Structures: Origins, Advantages, and Uses

- Chapter 2. Anisotropic Elasticity and Composite Laminate Theory

- Chapter 3. Derivation of the Governing Equations for Sandwich Plates (Panels)

- Chapter 4. Beams, Columns, and Rods of Composite Materials

- Chapter 5. Energy Methods for Sandwich Structures

- Chapter 6. Solutions for Rectangular Sandwich Plates

- Chapter 7. Dynamic Effects on Sandwich Panels

- Chapter 8. Thermal and Moisture Effects on Sandwich Structures

- Chapter 9. Elastic Instability (Buckling) of Sandwich Panels

- Chapter 10. Structural Optimization to Obtain Minimum-Weight Sandwich Panels

- Chapter 11. Sandwich Shells

- Chapter 12. Buckling of Sandwich Cylindrical Shells

- Chapter 13. Minimum-Weight Optimization of Sandwich Cylindrical Shells

- Appendix 1. Core Materials

- Appendix 2. Face Materials

- Appendix 3. American Society for Testing Materials (ASTM) Standards for Sandwich Structures and Materials

- Index