CHAPTER I

THE RAW MATERIAL

COTTON wool is a vegetable down which grows in tropical and sub-tropical climates. Its region may be defined as the areas lying 40° north and south of the Equator. Its requirements in respect of climate and soil could not be discussed with any advantage in this brief sketch, and, as Professor Dunstan has said, the agricultural chemistry of cotton is still in its infancy.1 The cottons known to commerce fall into two great classes, the Oriental and the Occidental, the Indian and the American, but botanically many species have been enumerated. The most important cotton - producing countries at the present time are the United States, India, Egypt, Brazil, and China ; but the last produces almost entirely for home consumption. Indian cottons, which have a very short staple, are grown chiefly at Hingunghât, Oomrawuttee, Broach, Dhollera, and Dharwar. At Dharwar, New Orleans seed has also been successfully raised. In India the cotton plant is reared in regions where long periods of drought are experienced, but the absence of rain for months together in these parts is rendered comparatively harmless by the character of the soil, known as black cotton soil, which is capable of retaining moisture for a long time. The quantity of cotton produced in America was not large until some time after the Revolution : the cotton used by the colonists was imported from Smyrna and Barbados. Now the quantity of cotton produced in America is enormous, and constitutes by far the most important source of supply.

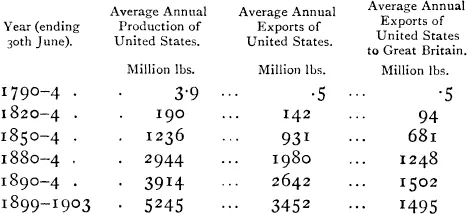

The increasing proportion sent to other countries than England is noticeable. It is also noticeable that the American crop has not kept pace with the need for cotton: thus, in the years 1870—1, 1880—1, 1890—1, and 1902—3, which may be taken as fairly typical, the world’s consumption of cotton in million bales advanced as follows: 4.9, 7.2, 10.3, 13.7; while the American crop, measured in the same way, moved from 4.4 in the first year to 6.6, 8.7, and 10.8 in the succeeding years mentioned above.

Sea Island cotton, which is raised along the coasts and on the islands of South Carolina and Georgia, between Charleston and Savannah, is the most valuable of all cottons grown, on account of the length, strength, and texture of its fibre. It is of an even, silky texture, and has a yellowish colour. It varies in quality from year to year with the climatic conditions under which it is raised, and requires very careful cultivation. The other variety of cotton grown in America is known as “Uplands,” from the district in which it is cultivated.

Cotton was introduced into Egypt some time prior to 1820 by Maho Bey, who had been Governor of Dongola and Sennaar, and its cultivation was encouraged by Mehemet Ali. An energetic Frenchman, Jumel by name, who had observed cotton in Maho Bey’s garden in 1820 and had started a plantation of his own, was placed in control of the Viceroy’s cotton fields. The imported industry succeeded beyond the dreams of its originators, and to-day Egyptian cotton is highly prized and has a large market. Its cultivation is confined to the delta and the parts which allow of irrigation from the Nile. The cotton fields can be flooded periodically without the plants sustaining injury owing to the dryness of the atmosphere. From Egypt we receive now on an average some 300 million lbs. a year, that is between a quarter and a fifth of our average imports of cotton from the United States.

The cotton harvest of the world begins in August at earliest. Everywhere it is gathered by hand, but much thought has been given to the problem of mechanical harvesting, and there is little doubt that in the future machinery will take the place of the tedious method at present employed. Before the separation of the seeds from the fibres is attempted, the wool is dried in the sun for some days. The removal of the seeds from the cotton was for years a great difficulty. The oldest device was to pass the cotton between rollers horizontally grooved, and placed sufficiently close together to prevent the passage of the seeds. This method was found to be suitable for Sea Island cotton, with its long straight staple, but not for the Upland cotton, in which the seeds are more completely embedded. Hence it was the Sea Island cotton of which the cultivation was most widely extended until the invention of the saw-gin. The following is an account of a roller machine as it was used in America for the Sea Island cotton. It is quoted by Baines from Hall’s1 travels in North America :—

“It consists of two wooden rollers of about an inch in diameter ; these are placed horizontally, parallel, and touching each other. Over them is fixed a sort of comb, having iron teeth two inches long and seven-eighths of an inch apart. This comb is of the same length as the roller, and is so placed that its teeth come nearly in contact with them. When the machine is set in motion, the rollers are made to revolve with great rapidity, so that the cotton being laid upon them, it is by their motion drawn in between the two, whilst no space is left for the seeds to pass with it. To detach these from the fibres of cotton in which they are enveloped, the same machinery which impels the rollers gives to the toothed instrument above a quick, wagging motion to and fro, by means of which the pods of cotton, as they are cast upon the rollers, are torn open just as they are beginning to be drawn in ; the seeds, now released from the coating which had encircled them, fly off like sparks to the right and left, while the cotton itself passes between the cylinders. The sharp iron teeth of the comb, moving with great velocity, sometimes break the seeds, then the minute pieces are instantly hurried on, and pass between the rollers with the cotton. These stray particles are afterwards separated by hand, a process which is called moting. Entirely to cleanse the cotton from any remaining fragment of seed, it is subjected to another process. This consists in whisking it about in a light wheel, through which a current of air is made to pass.”

From this description a good idea can be formed of the fundamental character of roller-ginning. The saw-gin, by which, for the first time, the seeds could be removed cheaply from Upland cotton, was the invention of Eli Whitney, of Westborough, in Massachusetts ; it has rightly been regarded as one of the half-dozen great inventions which helped to create the great centralised cotton industry of Lancashire. The principle of the machine is well brought out in the following account of its working, which was penned early in the nineteenth century :—

“The cotton is put into a receiver, or hopper, of considerable length compared with its width, one side of which is formed by a grating of strong parallel wires, about an eighth of an inch apart. Close to the hopper is a wooden roller, having upon its surface a series of circular saws, an inch or a half apart, which pass within the grating of the hopper to a certain depth. When the roller is turned, the teeth of the saws lay hold of the locks of cotton and drag them through the wires, whilst the seeds are prevented by their size from passing through, and fall to the bottom of the receiver, where they are carried off by a spout. The cotton is afterwards swept from the saws by a revolving cylindrical brush.”1

Machines which are modifications of Whitney’s gin are in general use to-day for cleaning cotton in the Southern States ; but as the system of the saw-gin has been found to injure the long-stapled cottons, a development of the roller-gin is employed for Sea Island, Egyptian, and Brazilian cottons. The roller-gin, even in its modern forms, deals slowly with the cotton to be cleaned ; while the Whitney machine gins rapidly, but so roughly as to damage much of the fibre that passes through it ; hence attempts, which have met with some success, are being made to improve the capacity of the former and to prevent the latter from cutting the fibres.

From the manufacturer’s point of view, the value of the cotton depends upon the length, strength, and fineness of the staple. Colour is also a matter of some importance. Formerly the main distinction in cottons was drawn between “yellow” and “white,” but now the two chief classes are “long-stapled” and “short-stapled.” Of Sea Island cotton, the long-stapled variety of America, I have already spoken. Long-stapled cottons are obtained also from Brazil, Demerara, the West Indies, and Egypt. Manufacturers can make substitutes for many cottons by mixing different sorts.

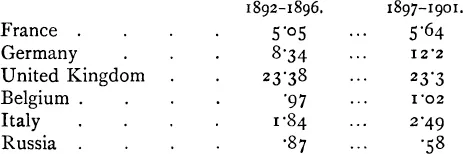

About three-quarters of the raw cotton of the world is raised in the United States, and about half of the raw cotton exports of the world come to Great Britain. The average values of the exports from the United States to different European countries in the five years ending in 1896, and the five years ending in 1901, are stated beneath :—

Raw cotton is admitted free into England, Germany, and France, but a duty is charged in Russia and Italy. In interpreting this table it must be remembered that the price of cotton has been far from stationary. The average prices of middling American cotton in the years to which the figures above relate were as follows, beginning with 1892: in pence per pound. Variations in price are occasioned partly by unforeseen alterations in demand, and partly by unexpectedly good or bad crops. The yields per acre differ sometimes a good deal : between the years 1896-7 and 1903-4 the annual yields per acre were 210, 257, 249, 197, 200, 194, 200, 168 lbs. The large share of the American crop which falls to the United Kingdom is explained chiefly by the extent of our manufacture. In a much less degree it is accounted for also by the fact that, in comparison with our consumption, the consumption of the Continent includes a greater proportion of the cheap short-staple variety of cotton which is obtained from India. It has been estimated that the distribution of the Bombay crop recently was 3.3 per cent, to Great Britain, 37.5 per cent, to the continent of Europe, 15 per cent, to China and Japan, .5 per cent, to Calcutta and the coast, and 43.7 per cent, for home consumption. The increasing proportion of cotton consumed by countries other than England will receive attention later.

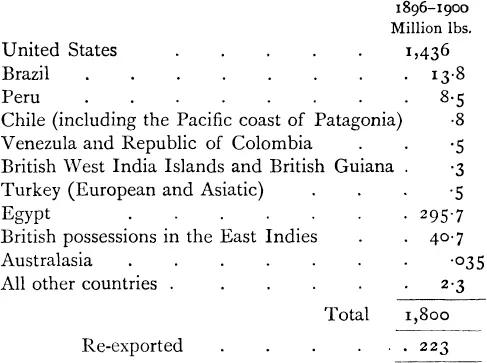

As regards the sources from which Great Britain draws her cotton, striking changes have taken place since the closing years of the eighteenth century. In 1786-90 the British West Indies contributed 75 per cent, of the cotton received by Great Britain ; the Mediterranean countries contributed 19 per cent, Brazil 8 per cent, the United States and India less than 1 per cent, and Egypt none at all, since the cotton plant was then as rare in Egypt as snakes are in Iceland. Compare these figures with the table below.

AVERAGE QUANTITIES OF RAW COTTON IMPORTED ANNUALLY INTO THE UNITED KINGDOM FROM THE FOLLOWING COUNTRIES IN THE PERIOD OF 1896-1900:

Probably the United States, India, and Egypt supply now about four-fifths of all the cotton used in the world. They export to Great Britain something over nine-tenths of all the cotton she receives.

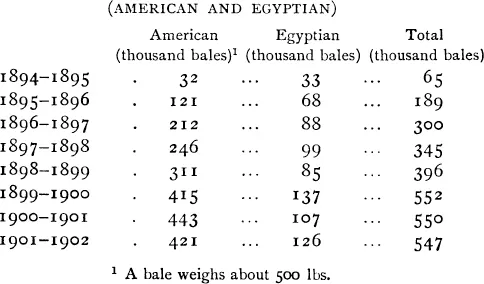

Large quantities of cotton now enter Manchester by the Ship Canal, but from six to eight times as much is still imported through Liverpool. The figures subjoined give the shipments through the canal from 1894 to 1902, each year being reckoned from September 1st to August 30th. A Manchester cotton-importing company is now in process of formation, or is actually formed, for increasing the importations through the canal and establishing a “spot” market in Manchester. In connection with importations through the Ship Canal it should be noted, for the benefit of those who do not know Lancashire and its industry, that the great majority of the mills are far from Manchester and that, therefore, were the bulk of the cotton used discharged at Manchester docks instead of at Liverpool docks, a “handling” would be saved in only a few cases, though in most the cost of transport by rail would be less from Manchester than from Liverpool.

IMPORTS OF COTTON TO THE PORT OF MANCHESTER (AMERICAN AND EGYPTIAN)

The question of the supply of cotton is agitating Lancashire and the Continent at the present time, owing largely to recent shortages of the crop, and a British Cotton Growing Association has been formed. A similar movement took place half a century ago, which resulted in the establishment of the Cotton Supply Association. This Association was instituted in April, 1857, that is some time before war broke out in the United States, or conflict had become imminent. It originated, according to the fifth annual report, “in the prospective fears of a portion of the trade that some dire calamity must inevitably, sooner or later, overtake the cotton manufacture of Lancashire, whose vast superstructure had so long rested upon the treacherous foundation of restricted slave labour as the main source of supply for its raw material.”1

Between 1840 and 1860 the American cotton crop increased about 100 per cent, while English and European spindles increased by about 150 per cent., and many began to feel that, apart from the question of slave-labour, the dependence on America was too exclusive, and that unless active steps were taken the supply of raw cotton might prove inadequate to meet the needs for it. The methods of the Association were stated thus ;—

“To afford information to every country capable of producing cotton, both by the diffusion of printed directions for its cultivation, and sending competent teachers of cotton planting and cleaning, and by direct communication with Christian missionaries, whose aid and co-operation it solicits ; to supply, gratuitously in the first instance, the best seeds to natives in every part of the world who are wi...