![]()

1

Responsible Textile Design and Manufacturing: Environmentally Conscious Material Selection

Ece Kalayci, Ozan Avinc, Arzu Yavas, and Semih Coskun

CONTENTS

1.1 Introduction

1.2 Environmentally Conscious Design

1.3 Environmentally Conscious Material Selection in Textile Production

1.3.1 Natural Fibers

1.3.2 Regenerated Fibers

1.3.3 Synthetic Fibers

1.3.4 Recyclable/Reusable Fibers

1.3.5 Biodegradable Fibers

1.3.6 Organic Natural Fiber Production

1.3.7 Alternative Cotton Programs: Better Cotton, Cleaner Cotton, Naturally Colored Cotton

1.4 Sustainability Measurements and Assessment Tools in Environmentally Conscious Manufacturing

1.4.1 Life Cycle Analysis (LCA) of Textile Materials

1.4.2 Carbon Footprint in Textile Production

1.4.3 Water Footprint in Textile Production

1.4.4 Social Responsibility in Textile Production

1.4.5 Sustainable Textile Production (STeP)

1.4.6 The Higg Index

1.4.7 Standards and Test Methods for Textile Sustainability

1.4.7.1 Restricted Substance List (RSL) Testing

1.4.7.2 Consumer Product Safety Improvement Act (CPSIA)

1.4.7.3 Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH)

1.4.7.4 Global Organic Textile Standard (GOTS)

1.4.8 Eco Labels

1.5 Innovative Options in Environmentally Conscious Textile Manufacturing

1.6 Conclusion

References

1.1 Introduction

The necessity and desire for clothing in ancient years has today turned into a huge textile industry that not only produces clothes but also has many different applications in our homes and in different fields such as construction, medical, agriculture, aviation, sports, and so on. The production rates of textile materials are increasing daily due to the growing world population, changes in consumption, and fashion trends. This rapid increase in production boosts the demand for raw materials and causes the consumption of tremendous amounts of clean water and energy resources. Chemical wastes and greenhouse gases resulting from chemical reactions harm the environment in many different ways, such as contributing to potential climate change and causing global warming (Fletcher, 2013; Muthu et al., 2012). Therefore, it cannot be denied that textile manufacturing processes and by-products may have harmful effects on the biophysical environment. For example, cotton and polyester, which are the most commonly used textile fibers, have critical problems in their life cycles (Waite, 2009; Shangnan Shui, 2013). Cotton cultivation needs a tremendous amount of clean water, leading to soil salinization. Moreover, many different chemicals, such as pesticides, insecticides, and so on, are required for cotton production to avoid various different pests and insects. Obviously, these kinds of negative effects result in some environmental issues. For instance, unsustainable and unrenewable petroleum is used to produce polyester (Sharma, 2013; Petry, 2008; Hayes, 2001). Synthetic fibers are oil-based materials, and the raw material of these fibers is unsustainable and on the verge of depletion due to limited petroleum reserves. Moreover, the waste accumulation problem of synthetic fibers is another important pollution problem. Therefore, to overcome all these possible negative effects of textile manufacturing on the environment and for a sustainable future, the responsible manufacturing of textile products is crucial.

Environmentally conscious design and manufacturing in textile production comprises the selection and use of sustainable, renewable, and biodegradable textile materials; reusability; recyclability; the use of new environmental textile production and finishing techniques leading to lower consumption of water, chemicals, and energy; and finally, using natural or natural-based auxiliary substances instead of synthetic chemicals, leading to a more environmentally friendly and sustainable world (Fletcher, 2013; Muthu et al., 2012; Maia et al., 2012).

Hence, important related issues such as environmentally conscious design, environmentally conscious material selection in textile production, assessment tools in environmentally conscious manufacturing (ECM), and innovative options in environmentally conscious textile manufacturing are discussed in detail in the following sections.

1.2 Environmentally Conscious Design

ECM is a system that involves various green approaches for addressing design (Desai and Mital, 2017), recycling (Lambert and Gupta, 2005; Igarashi et al., 2016), and other issues (Gungor and Gupta, 1999). Algorithms, models, and software (Kalayci and Gupta, 2013a; Kalayci and Gupta, 2013b) are required for efficient and responsible manufacturing. ECM has become an obligation for every industry as a result of increasing environmental awareness and imperative eco-friendly regulations. Ilgin and Gupta (2010) have classified ECM into four main issues: product design, reverse and closed-loop supply chains, remanufacturing, and disassembly.

It is necessary to carry out all operations, from the selection of materials to the final product, with environmental awareness to realize environmentally friendly textile production. It is also required to create a cycle in which the product can be recycled, reused, or remanufactured at the end of its lifetime. Conventional textile product design aims for a product with lower cost, higher functionality, and easier manufacturability. However, environmental concerns are forcing textile manufacturers and consumers to find greener ways to manufacture and to use textiles responsibly.

Traditional product development has the goal of achieving advancements in design in terms of cost, functionality, and efficiency. However, environmental issues are forcing designers to show special consideration for environmental aspects in various design processes. It is possible for product designers to make environment-friendly design choices, and a number of methodologies, such as Design for X (Veerakamolmal and Gupta, 2000), life cycle analysis (LCA) (Grote et al., 2007), and material selection (Isaacs and Gupta, 1997) have been developed (Ilgin and Gupta, 2010).

During the design of a textile product, designers should

• Consider the primary features that consumers may look for in the product

• Understand how consumers may use the product

• Follow developments in textile science and technology by collaborating with scientists

• Estimate the process steps required during the manufacturing of the product

• Question the applicability of alternative sources and methods

From cradle to grave, there are many negative social and environmental impacts arising at different stages of apparel production in the textile industry. High-volume production and low-price selling of apparel are strengthening these impacts with advancements in fast fashion (Steinberger et al., 2009).

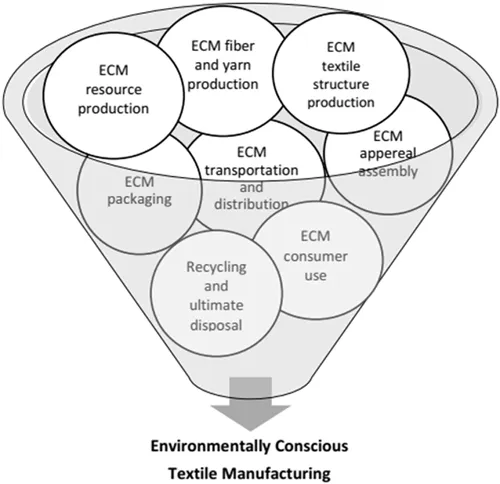

Apparel has a complicated production chain, including fiber, yarn, and textile production; assembly; packaging; transportation and distribution; retailing; and consumer use, recycling, and ultimate disposal (Lewis and Chen, 2006). A responsibly manufactured textile product should be environmentally conscious not only in terms of design, but also in material selection and manufacturing (Figure 1.1).

FIGURE 1.1

Environmentally conscious textile manufacturing. ECM: environmentally conscious manufacturing.

Material selection in textile production plays a critical role in environmentally conscious design and manufacturing.

1.3 Environmentally Conscious Material Selection in Textile Production

Mechanical properties, processability, and cost are the main parameters that affect material selection. In recent years, environmental factors such as recyclability, reusability, and biodegradability have started to affect material selection because of environmental awareness.

Material selection is the first step in product design and production. Environmentally conscious material selection is required for responsible textile design and manufacturing. Textile fiber is the smallest element of a textile structure. Yarn is produced by combining the fibers using various techniques called the spinning process and used to obtain two different types of textile structure by knitting and weaving. A nonwoven textile structure is obtained by entangling and bonding fibers mechanically, thermally, or chemically without the need for a yarn structure.

Textile fibers are mainly classified into natural fibers and man-made (chemical) fibers. Natural fibers are obtained from natural sources such as plants, animals, or minerals. The origin of the natural fibers affects the sub-classification of natural fibers. Plant fibers such as cotton, flax, jute, hemp, and so on are cellulosic natural fibers. Animal fibers (wool, mohair, silk, and so on) are protein fibers, which are obtained from different animals such as sheep, goats, camels, rabbits, caterpillars, and so on. Mineral fibers are another natural fiber class, which includes asbestos. Man-made fibers are subgrouped into regenerated fibers and synthetic fibers. Regenerated fibers are produced from a natural base material such as cellulose or protein. Viscose, modal, lyocell, casein, and soybean...