- 404 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

In Mining Engineering operations, mines act as sources of constant danger and risk to the miners and may result in disasters unless mining is done with safety legislations and practices in place. Mine safety engineers promote and enforce mine safety and health by complying with the established safety standards, policies, guidelines and regulations. These innovative and practical methods for ensuring safe mining operations are discussed in this book including technological advancements in the field. It will prove useful as reference for engineering and safety professionals working in the mining industry, regulators, researchers, and students in the field of mining engineering.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Mine Safety Science and Engineering by Debi Prasad Tripathy in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Civil Engineering. We have over one million books available in our catalogue for you to explore.

Information

1 Basics of Mine Safety Engineering

1.1 Introduction

Ever since the beginning of industrial scale mining in the 19th century, safety has been a major concern in the mining industry. Mine workers face a number of risks to their well-being including physical, ergonomic, and psychological problems. The most common causes of fatal injuries in the mining industry include roof fall, explosion, and fire in underground mines. Over the last few decades, a great deal of effort has been put into research and practical work to understand how major accidents can be prevented. Many countries have continuously improved existing standards, framed new rules and regulations, and employed advanced technology to improve safety in mines. Yet today, the mining industry is considered as one of the most unsafe industries, due to the continuous reoccurrence of accidents around the world.

Since 1901, around 278 and 99 major accidents have taken place in Indian coal and non-coal mines, and 505 and 84 major accidents have taken place in US coal and non-coal mines respectively (DGMS, 2018b; MSHA, 2017a). The majority of these accidents were due to noxious gases, fire, explosion, inundation, and roof fall. Some of these accidents killed thousands of mine workers while some affected only a few. All accidents in mines may or may not affect the mine workers, depending on the number of workers present at the accident location. Therefore, it is necessary to understand all types of possible hazards and risks that lead to fatal, serious, and reportable accidents.

Mine safety refers to the management of operations and events within the mining industry, for protecting miners by minimizing hazards, risks, and accidents. Most of the pertinent safety issues related to mining are addressed through promulgation of the relevant legislation, compliance, and best practices that are to be considered for the best possible protection of the mine workers. Employers are expected to abide by these laws and practices to ensure the maximum observance of safety at the workplace (Safeopedia, 2018). Mine safety covers various issues that affect the safety of equipment and personnel in the mining industry. The various issues are as follows:

- general safety issues that are common to all types of mines

- workplace safety issues that are directly related to the workplace

- process and production safety issues within the processes associated with the mining

- occupational health and safety issues particularly associated with the mining

- environmental safety issues associated with underground and surface hazards

- structural safety issues associated with mine construction and geological characteristics.

Mine safety engineering is an engineering discipline that ensures that engineered systems provide acceptable levels of safety. In mine safety engineering, risk assessment concepts such as hazard identification, risk analysis, and risk evaluation are applied to mine safety issues to keep the risk level as low as reasonably possible. Therefore, to understand the structure, causes, prevention, and control methods of accidents, a knowledge of mine safety engineering concepts is required. It involves considerable planning, engineering analysis, and logical approach to manage these risks.

1.2 Safety Nomenclature

Over the last four decades, although many international standards and guidelines have been framed to improve the safety in the mining industry, none of them have provided uniformity in the terminology to be used for safety management. The common definitions of terms used in the area of safety engineering and management are presented in Appendix A.

1.3 Principles of Safety Engineering

Safety engineering is an engineering discipline that ensures that engineered systems provide acceptable levels of safety; it is a subset of system safety engineering. Safety engineering, like any applied science, is based upon fundamental principles and rules of practice. It supports risk management programming. It is the application of engineering and management principles, criteria, and techniques to optimize safety. Safety engineering involves: (i) establishing context, (ii) hazard identification, (iii) risk evaluation, and (iv) control of hazards in man-machine systems that contain a potential to cause injury to people or damage to property (Nelson & Associates, 2007).

1.3.1 Establishing Context

Establishing context is essential to define how the safety management and safety engineering tasks will be carried out to ensure that safety requirements are met. In the establishing context step, the scope and limits of the task are defined, and they must cover the entire life cycle of mining.

1.3.2 Hazard Identification

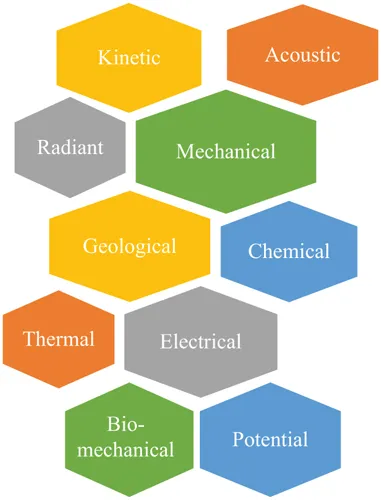

A hazard is defined as any source of potential damage, harm, or health effects to workers. Generally, a hazard when combined with some initiating event, will lead to harm. Therefore, the identification of hazards is the first and most important step in the risk assessment process. In hazard identification, all the hazards and risk factors that have the potential to cause harm are identified using system safety techniques. The most basic technique for identifying hazards is “energy analysis.” The damage or harm in any workplace cannot happen without the presence of some form of hazardous energy. Using the energy analysis technique, all the hazards related to the various forms of energy of an activity or task can be identified by identifying the types of energies present. The energy analysis technique simplifies the task of hazard identification, as it allows the identification of hazards by means of a finite set of search paths, recognizing that the common forms of energy that produce the vast majority of accidents can be placed into only ten descriptive categories as shown in Figure 1.1.

FIGURE 1.1 Types of hazardous energy sources.

The aim of the hazard identification step is to identify and prepare a list of potential hazards for the activity under study. Assessing and prioritizing the risk of the identified hazards will be done in the later stages of risk assessment process. The descriptions of the hazardous energy types are indicated below.

- Chemical Energy Hazards: Chemical energy hazards are associated with materials that are acidic, flammable, or toxic. The risks of the hazardous chemical energy are heat, pressure, fire, and explosion.

Examples of chemical energy hazards in the mining industry are fire and explosion. - Electrical Energy Hazards: Electrical energy hazards are commonly present in any workplace due to the use of electrically operated equipment and power lines. Electrical energy hazards can cause harm to workers in the following ways:

- electric shocks

- exposure to electric arc

- electric burns

Examples of electrical energy hazards in the mining industry are contact, induction, or arcing. - Mechanical Energy Hazards: Mechanical energy hazards involve system hardware components that cut, crush, bend, shear, pinch, wrap, pull, or puncture. Such hazards are associated with components that move in circular, transverse (single direction), or reciprocating (“back and forth”) motion. Traditionally, such hazards found in typical industrial machinery have been associated with the terms “power transmission apparatus,” “functional components,” and the “point of operation.” Examples of mechanical energy hazards in the mining industry are being caught in moving equipment, being hit by moving machinery, and vehicle collisions.

- Kinetic (Impact) Energy Hazards: Kinetic energy hazards are associated with the collision of objects in relative motion to each other. This would include the impact of objects moving toward each other, the impact of a moving object against a stationary object, falling objects, flying objects, and flying particles. Examples of kinetic energy hazards in the mining industry are falling objects, falling tools, or flying rocks, etc.

- Potential (Stored) Energy Hazards: Potential energy hazards include things that are under pressure, tension, or compression; or things that attract or repulse one another. Potential energy hazards involve things that are susceptible to sudden unexpected movement. Examples of potential energy hazards in the mining industry are tire failure, spring pressure release...

Table of contents

- Cover

- Half-Title

- Title

- Copyright

- Contents

- Preface

- Author

- Chapter 1 Basics of Mine Safety Engineering

- Chapter 2 Safety Issues in Opencast and Underground Mines

- Chapter 3 Behavior-Based Safety

- Chapter 4 Safety Culture in the Mining Industry

- Chapter 5 Accident Statistics, Analysis and Prevention in Coal and Non-Coal Mines

- Chapter 6 Safety Risk Assessment and Management

- Chapter 7 Safety Audit and Standardization

- Chapter 8 Occupational Health and Safety in Mines

- Chapter 9 Safety Education and Training

- Chapter 10 Innovations in Mine Safety Engineering

- Chapter 11 Disaster Management

- Chapter 12 Mine Rescue

- Chapter 13 First Aid and Ambulance Work

- References

- Appendix A: Safety Nomenclature

- Index