CHAPTER 1

Introduction

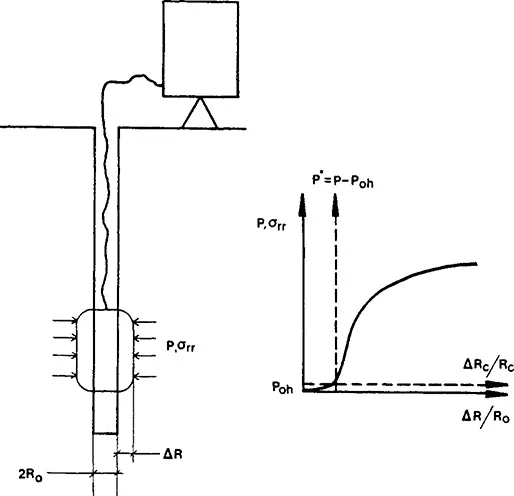

The purpose of this book is to provide guidelines for the proper use of the pressuremeter. This includes the proper way to perform a pressuremeter test, to reduce the data and to use the data in design. A 30 minute videotape has been prepared to cover these 3 topics (Briaud, 1989). The pressuremeter test consists of placing a cylindrical probe in the ground and expanding the probe to pressurize the soil horizontally (Figure 1). The pressure, p, on the soil (radial stress, σrr, at the cavity wall) and the relative increase in cavity radius, ΔRc/Rc, (hoop strain, εθθ, at the cavity wall) are obtained; therefore the pressuremeter test gives an in situ stress-strain curve of the soil. The pressuremeter test is repeated at various depths in order to obtain profiles of soil parameters.

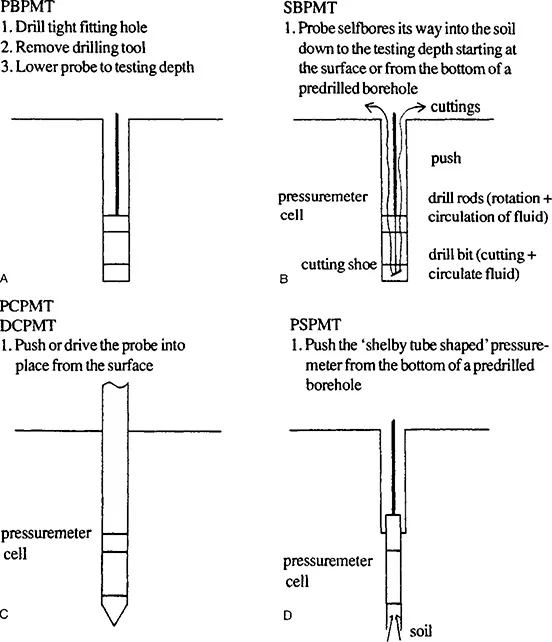

There are several different kinds of pressuremeters (Figure 2). They are the preboring pressuremeter (PBPMT), the selfboring pressuremeter (SBPMT), the cone pressuremeter either pushed (PCPMT) or driven (DCPMT) in place, and the pushed shelby tube pressuremeter (PSPMT). These various pressuremeters differ mainly by the way the probe is placed in the ground. The scope of this book is limited to the preboring pressuremeter; the preboring pressuremeter is the one which is used most commonly in practice. The word pressuremeter will be used to mean preboring pressuremeter from this point on. The scope of this book is not limited to soils; it includes some aspects of testing and design in rock.

The design applications of the preboring pressuremeter (PBPMT) test include: shallow foundations under vertical loads, deep foundations under vertical and horizontal loads, ground anchors, cantilever drilled shaft walls and anchored bulkheads, pavements, ground improvement and compaction control. The preboring pressuremeter (PBPMT) test is of little use in slope stability analysis and in conventional active and passive earth pressure problems although there is potential for future development in the earth pressure problem area.

Kogler, in 1933 in Germany, is credited with having developed the first preboring pressuremeter; however Kogler did not pursue his idea. Menard, in 1955, in France, developed a preboring pressuremeter to measure the in situ soil deformation properties and started his own company. Fukuoka, in 1959 in Japan, developed the ‘Public Works Research Type K-Value Tester,’ a preboring pressuremeter, to obtain lateral soil moduli values. That same year Menard built the ‘slotted tube’ where the probe protected inside a slotted casing was inserted by driving into the ground. In 1963, Menard, from the experience gathered, published the first equations and charts relating pressuremeter results directly to foundation settlement and bearing capacity. In an effort to improve the procedure, Jezequel, in 1965 in France, developed the first selfboring pressuremeter at the Laboratoire des Ponts et Chaussees. Jezequel’s SBPMT called the PAF has been upgraded over the years. In 1966, Suyama, Imai and Ohya, of the Oyo Corporation, developed the Lateral Load Tester and later on the Elastmeter 100; both are preboring pressuremeters.

Figure 1. The pre-boring pressuremeter test.

Figure 2. Different pressuremeters and insertion procedures.

Wroth and Hughes, in 1971 in England, developed a selfboring pressuremeter at the University of Cambridge which they called the Camkometer; this unit is now sold commercially by Cambridge In Situ. In 1975 the Building Research Establishment in the UK built a pushed shelby tube pressuremeter (PSPMT) for offshore applications; this pressuremeter is now operated by Stressprobe. In 1978, Briaud and Shields in Canada, developed a small pressuremeter for pavement design now known as the Pencell and sold by Roctest. In 1978 the Russian Research Institute of Foundations and Underground Bases (NIIOSP) developed an automatic pressuremeter called the PA108. Also in 1978, the French Petroleum Institute (IFP) developed a selfboring pressuremeter for offshore investigation called the PAM. The book by Baguelin, Jezequel and Shields on the Pressuremeter and Foundation Engineering was published in 1978.

In 1981, Hergheleglu and Unchesel reported that a prototype pressuremeter was manufactured in Romania. In 1982, Briaud and his co-workers at Texas A&M University developed the Texam, a preboring and selfboring pressuremeter now sold by Roctest. In 1982 also the Laboratoire des Ponts et Chaussees in conjunction with the Techniques Louis Menard developed the LPC-TLM pressio-penetrometer for shallow offshore penetrations; this probe is a cone pressuremeter inserted by vibrations. The Symposium on the Pressuremeter and its Marine Applications took place in Paris in 1982. From 1982 to 1986 efforts have been made by various groups to develop cone pressuremeters; these groups include Cambridge In Situ, Fugro B.V., Hogentogler, Roctest, Texas A&M University, and the University of British Columbia. In 1984, Bonne Esperance in France introduced the PAC, an automated version of the Menard pressuremeter. In 1984, both Roctest and Cambridge In Situ developed high-pressure pressuremeters for testing in rock. In 1986, the Second International Symposium on the Pressuremeter and its Marine Applications took place at Texas A&M University. In 1988 an ASTM standard was published for Pressuremeter Testing in Soils (ASTM D4719-87). In 1990, the Third Symposium on the Pressuremeter took place at Oxford.

In parallel with this equipment development, progress has been made in the interpretation and use of the pressuremeter data in France, England, Japan, Canada and more recently in Italy, Norway and the United States.

CHAPTER 2

Various types of equipment

2.1 Preboring Pressuremeters (PBPMT)

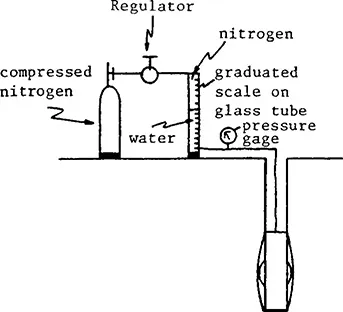

There are essentially four main types of PBPMT on the market today. The first type has a probe divided into three cells: one measuring cell and two guard cells (Figure 3). The purpose of the guard cells, which are inflated with gas, is to isolate the expansion of the measuring cell from end effects. The measuring cell is inflated with water. The rubber membrane of the probe is protected against puncture by overlapping steel strips. The pressure source is a compressed nitrogen bottle. The increase in volume of the measuring cell is indicated by pressure gauges. The Menard pressuremeter from Bonne Esperance is such a preboring pressuremeter.

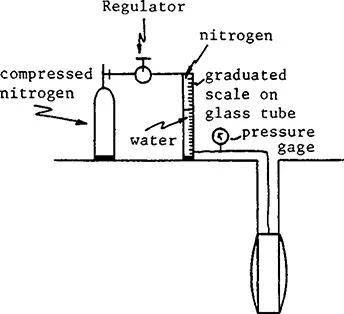

The second type is identical to the first type except that the probe is made only of one cell (Figure 4), long enough to ensure that the end effects are negligible. The LLT (Lateral Load Tester) of Oyo is such a preboring pressuremeter.

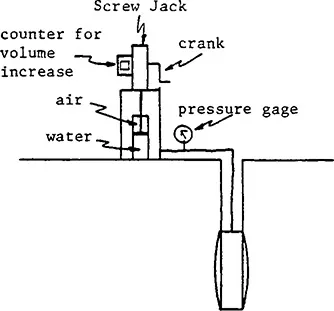

The third type is identical to the first type except that the probe is made only of one cell (Figure 5), long enough to ensure that the end effects are negligible. The probe is inflated with water. The pressure source is a screw jack which moves a piston forcing water into the probe. The increase in volume of the probe is measured by measuring the travel of the piston with a dial gauge or through a counter recording the number of revolutions of the screwjack. The pressure is indicated by pressure gauges. The Texam from Roctest is such a preboring pressuremeter. This unit also accomodates a selfboring probe: the Boremac.

The fourth type has a probe made of only one cell long enough to ensure that the end effects are negligible. The probe is inflated with gas. The pressure source is a compressed nitrogen bottle. The increase in radius of the probe is measured by strain-gaged cantilevered arms which follow the inside of the membrane as it expands. The pressure is indicated by pressure gages. The Tri-Mod from Roctest is such a preboring pressuremeter.

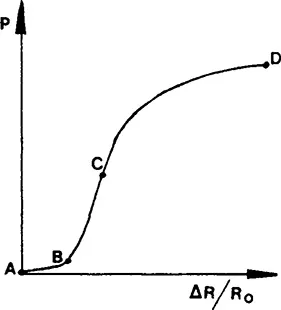

A typical result from a preboring pressuremeter test is shown on Figure 6. From A to B the probe is coming into contact with the borehole wall. From B to C there is a phase of linear behavior. Beyond C the soil is progressively yielding, up to a limit pressure.

Figure 3. Menard GC pressuremeter.

Figure 4. Oyo Lateral Load Tester.

Figure 5. Texam pressuremeter from Roctest.

Figure 6. Pre-boring pressuremeter curve.

2.2 Selfboring Pressuremeters (SBPMT)

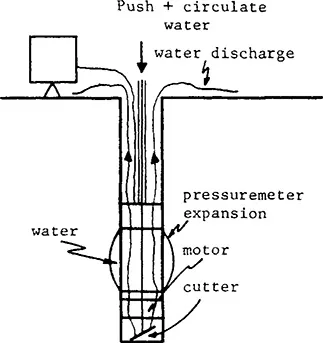

There are essentially three types of SBPMT on the market today. In the first type, the cutter is powered by a small motor housed inside the probe (Figure 7). The probe is made of one cell and is inflated with water. The pressure source is a screw-jack which moves a piston forcing water into the probe. The increase in volume is measured through a miniature flowmeter. The pressure is indicated by pressure gauges. The PAF 76 from the Laboratoire des Ponts et Chaussees is such a selfboring pressuremeter.

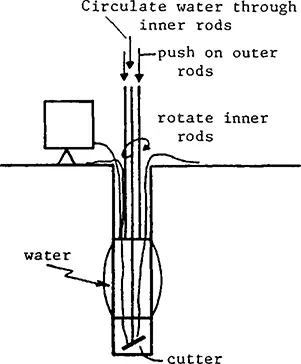

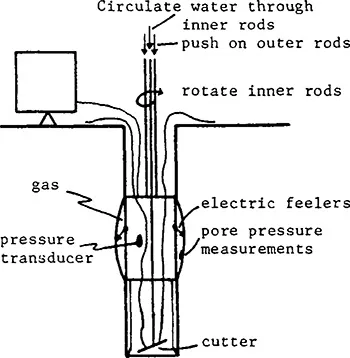

In the second type, the cutter is powered from the surface through a set of drilling rods (Figure 8). The probe is made of one cell and is inflated with gas. The increase in radius of the probe is measured by three electric feelers located at midheight of the probe. The pressure is measured by pressure transducers in the probe and also by pressure gauges. Pore pressures are measured by porous stone pore pressure transducers which are rubber-glued to the membrane. The Camkometer from Cambridge In Situ is such a unit.

Figure 7. PAF 76 from Laboratoire Central des Ponts et Chaussees (LCPC).

Figure 8. Camkometer from Cambridge In Situ.

Figure 9. Texam (SBPMT Option) from Roctest.

In the third type, the cutter is powered from the surface through a set of drilling rods (Figure 9). The probe is made of one cell inflated with water. The pressure source is a screw-jack pushing a piston. The increase in volume is measured from the displacement of the piston. The pressure is read on pressure gauges. The selfboring option of the Texam unit called the Boremac is such a selfboring pressuremeter.

A typical result from a s...