Microbial Fermentation and Enzyme Technology

- 342 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Microbial Fermentation and Enzyme Technology

About this book

The discovery of enzymes as biocatalysts has led to various biotechnological developments. The capability of enzymes to catalyse various chemical reactions both in vivo and in vitro has led them to applications in various industries, such as food, feed, pharmaceutical, diagnostics, detergent, textile, paper, leather, and fine chemical industries. Microbial Fermentation and Enzyme Technology mainly focuses on production and application of enzymes in various industries. Further, it also discusses recent developments in enzyme engineering particularly those involved in creating and improving product formations through enzyme and fermentation technology.

Salient features:

Includes current research and developments in the area of microbial aspects in different fields like food, chemicals, pharmaceutical, bioprocess, etc.

Discusses various enzymes that are used in refinement of environmental pollutions and its application in different industrial sectors

Focuses on production and application of enzymes in various industries

Highlights recent developments in enzyme engineering with respect to its application in textile, pharmaceutical, nanobiotechnology, bioremediation and many other related fields.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Introduction of Fermentation and Enzyme Science

Monika Choudhary, Sunanda Joshi and Nidhi Srivastava

1.1 Introduction

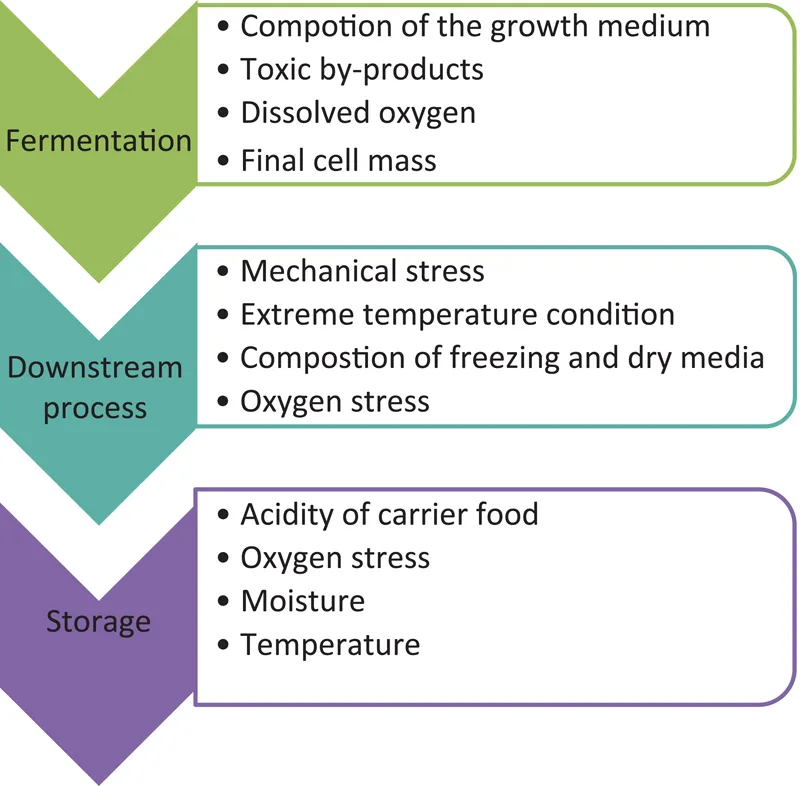

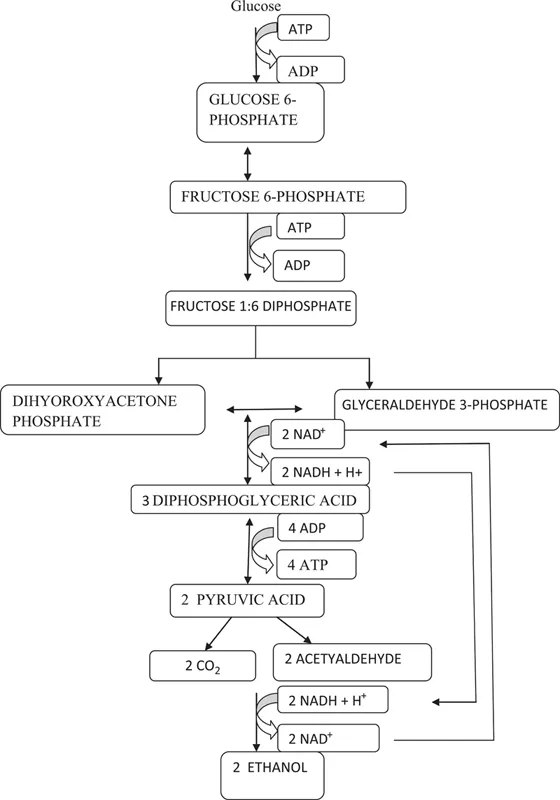

1.2 Basic Principle of Fermentation

1.3 Biochemical Process of Fermentation

“Microbial fermentation has been used for such purposes for many commercial products and enables novel techniques to support sustainable manufacturing and screening for microorganisms which produce novel enzymes, monitoring enzyme production in fermenters...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Preface

- Editors

- Contributors

- List of Abbreviations

- 1. Introduction of Fermentation and Enzyme Science

- 2. α-Amylases: An Overview on Molecular Structure and Biotechnological Perspectives

- 3. Study of α-Amylase Based on their Compositional Parameters of Its Gene Along with Its Protein Structure

- 4. Microbial Enzymes in Food Industry: Types and Applications

- 5. Fermented Foods for Health: Processes and Prospects

- 6. Advances in Enzymatic Applications in Food Industry

- 7. Role of Enzymes in Development of Functional Foods and Food Products

- 8. Application of Immobilized Cells and Enzymes in the Food Industry

- 9. Dextransucrase: A Microbial Enzyme with Wide Industrial Applications

- 10. Trends in Biosensors and Role of Enzymes as Their Sensing Element for Healthcare Applications

- 11. Application of Bile Salt Hydrolase Enzyme in Cholesterol Lowering

- 12. Fermentative and Enzyme-Assisted Production of Phenolic Antioxidants from Plant Residues

- 13. Relevance of Microbial Enzymes in Textile Industries Emphasizing Metabolic Engineering Panorama

- 14. Microbial Degradation of Organophosphate Pesticides: A Review

- 15. Microbial Production of Xylitol: A Cost-Effective Approach

- 16. Enzymes: Key Role in the Conversion of Waste to Bioethanol

- 17. Microbial Laccase: A Vanguard Biocatalyst and Its Potentiality towards Industrial Applications

- 18. Biofuel Cellulases: Diversity, Distribution and Industrial Outlook

- 19. Enzymatic Hydrolysis of Lignocellulosic Biomass Using Engineered Microorganisms and In Silico Approaches for Enhanced Enzyme Production: A Review

- 20. Agrowaste to Ethanol: Orchestrated by Enzymes from Microbes

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app