- 206 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Wet Scrubbers

About this book

A basic technical book on the design and application of gas cleaning technologies that use liquids, first published in the 1980's and used by plant and environmental engineers, regulatory personnel, and others concerned with air pollution. The second edition enlarges the discussion on the theory of

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

CHAPTER 1

Application Engineering Basics

1.1 INTRODUCTION

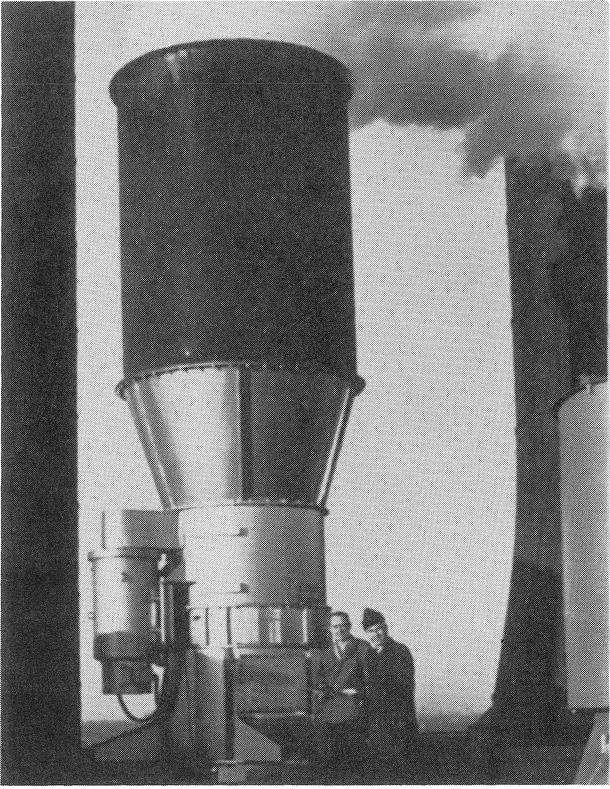

In the industrial world, scrubbers have been used for a long time. In 1836, for example, a packed tower absorber scrubber patent was issued. One hundred years later (in 1935) the English were removing 98 % of the SO2 in flue gas scrubbers. A particulate control scrubber was patented in 1901 extending the recognized use to both gas and particle control. Even incinerators, which can be good pollution control devices in themselves, may require scrubbers to enable the emissions to meet the regulations. Figure 1.1 shows the stack of a wet scrubber system on a city of Detroit municipal incinerator. Note the characteristic brilliant white scrubber plume that occurs during cold weather.

1.1.1 Scrubbing System Inputs

Application engineering for air pollution control equipment requires a knowledge of the process to which the system will be applied and of the specific equipment which will be utilized to control the emissions.

Regardless of the vendor’s name, applications engineering begins with some basic calculations. These calculations serve to provide gas flow data from which liquid flow, pressure drop, droplet removal, evaporation rate, and equipment proportioning data are derived. The basic calculations involve two areas: (1) determination of carrier gas conditions, and (2) determination of pollutant characteristics.

In the first area, psychrometric data are used to determine the following information:

• saturated volume

FIGURE 1.1. Characteristic wet scrubber plume in cold weather.

• scrubber outlet temperature

• scrubber outlet gas density and pressure

• evaporation rate

• outlet enthalpy

In the second area, gas and/or particulate data are synthesized to provide the following:

• particulate size distribution

• pressure drop

• inlet concentrations

• required efficiency

• partial pressure of contaminant gases

• cooling effects (sensible)

• exothermic or endothermic reaction effects

• wear characteristics

The potential user of air pollution control equipment must provide to the designer the following information so that the foregoing may be calculated:

• inlet gas volume, temperature, humidity and pressure

• peak particulate and gas loading

• average particulate and gas loading

• inlet scrubbing liquid

• particulate size distribution

• means of disposal of contaminant

The preceding data may be obtained through the use of a stack test or by diagnostic testing. Diagnostic testing does not attempt to appear as a compliance test. Diagnostic testing is the extraction of data through system testing designed to produce the variables needed by the designer in the solution of the problem. It may involve particulate distribution analyses, photography of the stack or emissions source, material balances and the like.

The means of disposal of the contaminant must be investigated at the outset. If sewering of the contaminant is permitted, the local regulations must be investigated as to concentration limits, additive limits, or other constraints. If the waste must be treated, the plant process must be investigated to determine overlap processes that may be utilized in the cleanup system. This may involve the blending of a caustic flow from one part of the plant with an acidic scrubber wash water or the addition of the scrubber underflow at a specific point in the facility’s treatment system. If no treatment system exists, the requirement must be considered by the designer. A system dedicated only to the scrubber may be imperative.

Many companies perform this data acquisition function themselves; others hire testing or consulting firms to provide these data and a technology assessment (TA). The TA outlines the problem and investigates alternative technology currently in use in the solution of the problem.

From the input data, one can calculate the Carrier Gas Conditions. This procedure involves the determination of the specific humidity (weight of water vapor per pound of dry gas) and uses psychrometric charts to determine the saturation temperature. These charts also provide the saturated gas conditions, such as temperature, outlet humidity and outlet enthalpy.

Section 1.3 describes these basic calculations for reference in the solution of many industrial wet scrubber applications problems. Vendors are an alternate source of applications information; however, one must keep in mind that a...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Preface

- Preface to the First Edition

- Acknowledgements

- Introduction

- Nomenclature

- Chapter 1. Application Engineering Basics

- Chapter 2. Fiberbed Filters and Wet Scrubbing

- Chapter 3. Scrubber Applications

- Chapter 4. Maintenance and Control

- Chapter 5. Testing Wet Scrubbers

- Chapter 6. Suggested Readings

- Index

- About the Authors

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Wet Scrubbers by Howard D. Hesketh,Kenneth C. Schifftner in PDF and/or ePUB format, as well as other popular books in Biological Sciences & Environmental Management. We have over one million books available in our catalogue for you to explore.