eBook - ePub

Drilling and Blasting of Rocks

- 408 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Drilling and Blasting of Rocks

About this book

Rock breakage with explosives has existed since the seventeenth century when black powder came into use in mining. Since then it has progressed from the invention of dynamite to the use of heavy ANFO. During the past two decades, there have been numerous technical contributions which have brought a better understanding of rock fragmentation with explosives, an improvement in drilling equipment and a noticeable evolution in the development of new explosives and blasting accessories. The Geomining Technological Institute of Spain (ITCE), aware of this progress and of the importance which the breakage process has acquired in mining and civil engineering projects, has ordered the publication of Drilling and Blasting of Rocks. The purpose of this Handbook is to give basic knowledge of the drilling systems, the types of available explosives and the accessories and the parameters that intervene in blast designing, whether controllable or not; at the same time the objectives and contents contribute to improved safety in mining. The Handbook is meant for all professionals who are involved with explosives in mining operations and civil engineering projects, as well as for students of technical schools.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Drilling and Blasting of Rocks by C. Lopez Jimeno,E. Lopez Jimeno,Francisco Javier Ayala Carcedo in PDF and/or ePUB format, as well as other popular books in Physical Sciences & Geology & Earth Sciences. We have over one million books available in our catalogue for you to explore.

Information

CHAPTER 1

Rock drilling methods

1.1 Introduction

Rock drilling, in the field of blasting, is the first operation carried out and its purpose is to open holes, with the adequate geometry and distribution within the rock masses, where the explosive charges will be placed along with their initiating devices.

The systems of rock drilling that have been developed and classified according to their order of present day applicability are:

– Mechanical: Percussion, rotary, rotary-percussion.

– Thermal: Flame, plasma, hot fluid, Freezing.

– Hydraulic: Jet, erosion, cavitation.

– Sonic: High frequency vibration.

– Chemical: microblast, dissolution.

– Electrical: Electric arc, magnetic induction.

– Seismic: Laser ray.

– Nuclear: Fusion, fission.

Even though there is an enormous variety of possible rock drilling systems, in mining and civil engineering drilling is presently carried out, almost exclusively, by mechanical energy. Therefore, in this handbook only the mechanical means will be discussed, reviewing the fundamentals, tools and equipment for each of them.

The main components of a drilling system of this type are: the drilling rig which is the source of mechanical energy, the drill steel which is the means of transmitting that energy, the bit which is the tool that exercises that energy upon the rock, and the flushing air that cleans out and evacuates the drilling cuttings and waste produced.

1.2 Types of Drilling Operations used in Rock Breakage

Within the large variety of excavations using explosives, numerous machines have been developed which can be classified in two types of drilling procedures:

– Manual drilling. This is carried out with light equipment that is hand held by the drillers. It is used in small operations where, due to the size, other machinery cannot be used or its cost is not justified.

– Mechanized drilling. The drilling equipment is mounted upon rigs with which the operator can control all drilling parameters from a comfortable position. These structures or chasis can themselves be mounted on wheels or tracks and either be self-propelled or towable.

On the other hand, the types of work, in surface as well as in underground operations, can be classified in the following groups:

– Bench drilling. This is the best method for rock blasting as a free face is available for the projection of material and it allows work to be systemized.

It is used in surface projects as well as in underground operations, usually with vertical blasmóles, although horizontal holes can be drilled on occasion.

– Drilling for drifting and tunnelling. An initial cavity or cut must be opened towards which the rest of the fragmented rock from the other charges is directed. Blast-hole drilling can be carried out with hand held drills, but the trend is towards total mechanization, using jumbos with one or various booms.

– Production drilling. This term is used in mining operations, fundamentally underground, to describe the labors of ore extraction. The equipment and methods used vary with the exploitation systems, having the common factor of little available space in the drifts for blast-hole drilling.

– Drilling for raises. In many underground and civil engineering projects it is necessary to open raises. Although there is a tendency to apply the Raise Boring method, still today the long blasthole method is used as well as other special drilling systems combined with blasting.

– Drilling rocks with overburden. The drilling of rock masses which are covered with beds of unconsolidated materials calls for special drilling methods with casing. This method is also used in underwater operations.

– Rock supports. In many underground operations and sometimes in surface ones it is necessary to support the rocks by means of bolting or cementing cables, in which drilling is the first phase.

1.3 Fields of Application for the Different Drilling Methods

The two most used mechanical drilling methods are rotary-percussion and rotary.

– Rotary-percussive methods. These are the most frequently used in all types of rocks, the top hammer as well as the down-the-hole hammer.

– Rotary methods. These are subdivided into two groups, depending upon if the penetration is carried out by crushing, with tricones or by cut with drag bits. The first system is used in medium to hard rocks, and the second in soft rocks.

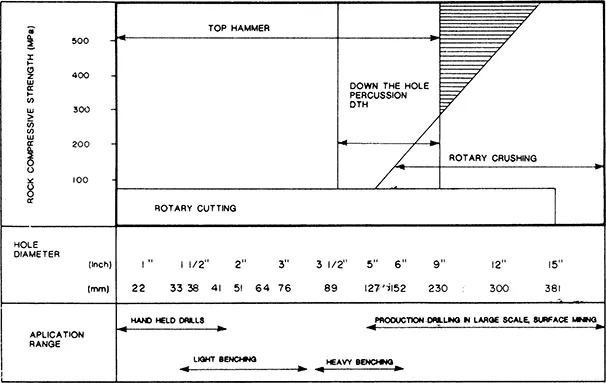

By taking into account the compressive strength of the rocks and the drilling diameter, the fields of application of the different methods can be defined as reflected in Fig. 1.1.

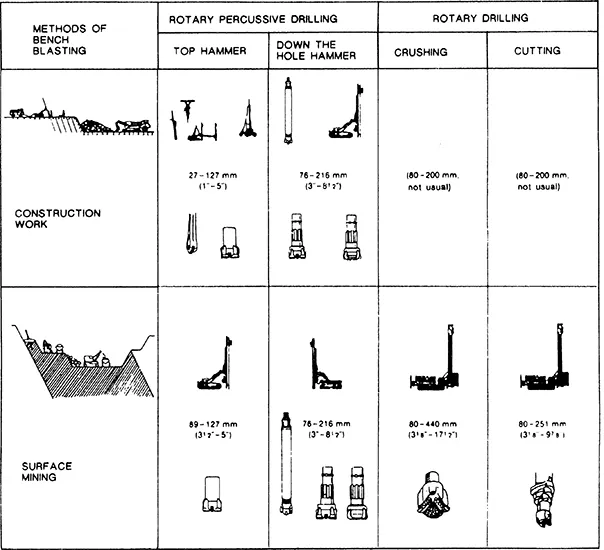

On the other hand, depending upon the type of mining or civil engineering surface project, the most common equipment and diameters for bench blastings are indicated in Fig. 1.2.

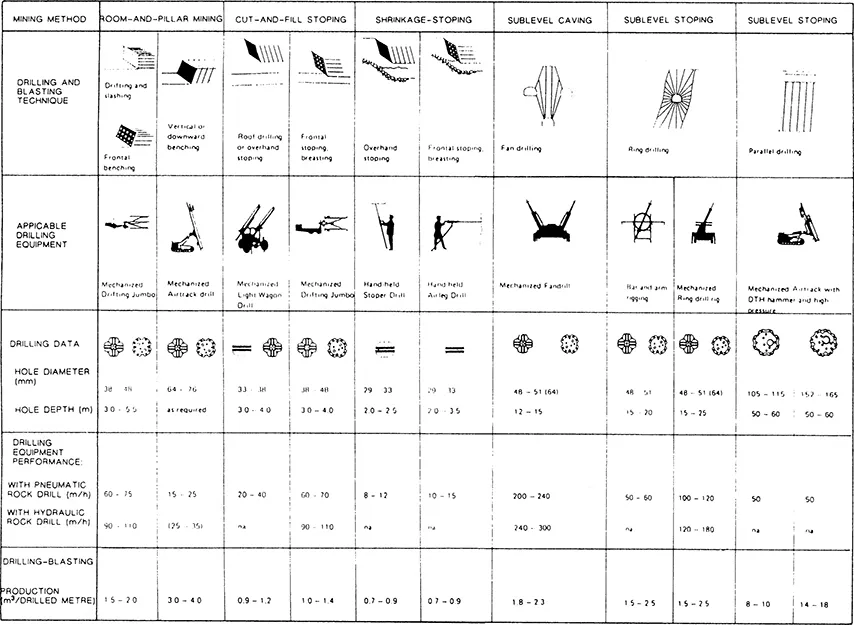

In the same manner, the most frequently used equipment for the different underground mining methods and the characteristic drilling data are indicated in Fig. 1.3.

Other criteria to be accounted for in the selection of drilling equipment are: cost, mechanical design, maintenance and service, operative capacity, adaptability to equipment of the exploitation, and the work area conditions (accessability, type of rock, sources of energy, etc.).

Fig. 1.1 Fields of application for drilling methods as function of the compressive strength of the rocks and the diameters of the blastholes.

Fig. 1.2 Drilling methods for surface operations (Atlas Copeo).

Fig. 1.3 Drilling methods for underground operations (Atlas Copeo).

1.4 Classiftcation of the Rocks and their Principal Physical Properties

Blasthole drilling is almost always carried out in rock masses. For this reason it is important, before starting an operation, to know the different types of materials and their basic properties.

The rock characteristics depend largely upon their origin, divided into three large groups, which will be subject to consideration in the following paragraphs.

1.4.1 Rock classification according to their origin

1.4.1.1 Igneous rocks

Igneous rocks are formed by solidification from a molten mass, called magma, which is a mixture of dissolved rock and gas material. If the rock has cooled in contact with air or water from the earth’s surface it is classified as extrusive or volcanic igneous rock. When the magma cools underneath the surface of the earth it forms intrusive or plutonic igneous rock.

The rate of cooling of the magma gives the grain size of the crystallized minerals; large if it is slow, and small if it is rapid. In the first instance a rock called pegmatite is formed, and in the second it is called aplite. An intermediate case is denominated porpyhry, in which large crystals are observed within a fine grained mass or matrix. These three types are usually found in dike form with strengths that go from one to dozens of meters. The most normal is that of a moderate cooling time which produces a rock mass with a medium size grain, from 1 to 5 mm.

The composition of magma varies during its cooling process because fractioned cristallization is produced depending upon the pressure and temperature of each moment. Also, the residual liquid can react with the minerals that are already solidified and change their chemical content and, again, the original chemical composition of the magmas can have been very different.

The diverse physical and chemical conditions that exist during solidification of magma give the large variety of igneous rocks. They are formed by different minerals, of various sizes and are grouped in diverse ways, the result being that their physical and chemical characteristics are very heterogeneous. Therefore, their behavior when confronted with fragmentation, cutting, wear or meteorization can be varied; although igneous rocks that have not been meteorized, as far as drilling goes, are all hard and compact.

If the rock has a SiO2 content that is higher than 62%, it is geochemically denominated acid, between that value and and 52%, it is intermediate, between 45 and 52%, basic, and lastly, when lower than 45% it is ultrabasic. In the same sense that igneous rocks are poorer in silica, they are richer in ferromagnesian silicates. The acids are more abrasive and harder than the basic ones, but they are also more dense and resistant to impact.

1.4.1.2 Metamorphic rocks

Metamorphic rocks are derived from other pre-existing endogenic or exogenic rocks through important transformations of their mineral components. These marked changes are produced by the necessity of stabilizing their minerals under the new conditions of temperature, pressure and chemism.

These rocks are intermediate in physical and chemical characteristics, between the igneous and the sedimentary, because they ...

Table of contents

- Cover Page

- Title Page

- Copyright Page

- Contents

- Foreword

- Preface

- Acknowledgements

- 1 Rock drilling methods

- 2 Rotary percussive drilling

- 3 Rotary percussive drilling accessories

- 4 Rotary drilling with rolling tricone bits

- 5 Rolling cone rock bits

- 6 Rotary drillling with cutting action

- 7 Special drilling methods and mounting systems

- 8 Compressors

- 9 Thermochemistry of explosives and the detonation process

- 10 Properties of explosives

- 11 Industrial explosives

- 12 Explosive selection criteria

- 13 Blasting accessories

- 14 Initiation and priming systems

- 15 Mechanized systems for charging and dewatering blastholes

- 16 Mechanisms of rock breakage

- 17 Rock and rock mass properties and their influence on the results of blasting

- 18 Characterization of the rock masses for blast designing

- 19 Controllable parameters of blasting

- 20 Bench blasting

- 21 Blasting in other surface operations

- 22 Blasting for tunnels and drifts

- 23 Shaft sinking and raise driving

- 24 Underground production blasting in mining and civil engineering

- 25 Contour blasting

- 26 Underwater blasting

- 27 Initiation sequence and delay timing

- 28 Evaluation of blast results

- 29 Secondary fragmentation and special blastings

- 30 Planning the work of drilling and blasting

- 31 Structure and building demolition

- 32 Optimizing costs of fragmentation with drilling and blasting

- 33 Land vibrations, air blast and their control

- 34 Flyrocks and their control

- 35 Safety measures for drilling and blasting operations

- Conversion factors

- General information, weight of materials

- Glossary

- Subject Index