- 244 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Hands On Water and Wastewater Equipment Maintenance, Volume II

About this book

Hands-On Water/Wastewater Equipment Maintenance, Volumes 1 and 2 deals with equipment maintenance as individual components, not as complete machines, allowing more information about the design, application and maintenance requirements of machinery to be presented. This work-related inventory of wastewater covers plant components where breakdowns most frequently occur. The text explains the design, operation and maintenance of equipment critical to plant functioning; motors, pumps, blowers, mixers and more. The author demonstrates how careful attention to specific equipment parts and operation, especially through systematic maintenance, will lead to fewer breakdowns and more rapid repairs. These texts cover basic operating characteristics of machinery components, making them a valuable reference source as well as a training and maintenance manual.Written in easy-to-understand language, without complex formulas or technical theories, Hands-On Water/Wastewater Equipment Maintenance Volumes 1 and 2 provides you with basic information to help you acquire a general understanding of how components function and how to keep equipment operating properly. These two volumes belong in every water and wastewater treatment plant as a reference and manual for equipment maintenance. The hands-on approach provides maintenance operators, crew leaders and supervisors with practical information about how the machinery they work with every day functions, and how to keep it running smoothly.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Hands On Water and Wastewater Equipment Maintenance, Volume II by Barbara Renner in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Environmental Management. We have over one million books available in our catalogue for you to explore.

Information

CHAPTER 1

Positive Displacement Pumps

1.01 A great variety of positive displacement pumps are used in water/wastewater utilities as well as industrial and chemical manufacturing companies for many different applications. Smaller size pumps are often used for chemical feed or metering applications, sometimes handling less than 1 quart per day. Larger pumps, on the other hand are used to transfer fluids or materials having viscosities that range from water (1.00 centistokes) to heavy slurries (5,000 centistokes).

1.02 Positive displacement pumps of a particular style (plunger, diaphragm, etc.) can often be used for either metering/chemical feed and/or fluid transfer applications. However, even though the pumps may be similar in style, they are manufactured very differently. To simplify the explanation of the contruction and operation of the various styles of pumps, they will be categorized by application and then subdivided by style. Although, this might lead to some repetition, the text will be easier to follow.

METERING/CHEMICAL FEED PUMPS

1.03 Although, there are only a few styles of metering pumps (plunger, diaphragm, and peristaltic), there are many varieties made of each style. Manufacturers often make the different varieties to fit specific applications, but more often they are based on the manufacturer’s desire to offer unique materials or construction features that are different from the competition.

1.04 The selection of a metering pump for a given application is not too invloved. Selection criteria include the characteristics of the fluid to be pumped (including its viscosity, abrasiveness, and corrosiveness), the volume of the fluid to be pumped, the duty cycle, and the suction and discharge head conditions that it must meet.

1.05 To meet the demands of different chemical compounds, manufacturers offer a wide variety of materials that are used in the wetted (internal) parts of the pump. In most cases, a single material can be used for a broad range of fluids. This permits a pump to be used for a number of applications without requiring any special design features. Sometimes, however, a material that uses specific formulated compounds is more effective when used with only a few chemicals. Usually, this gives the wetted components a longer life and saves on maintenance repairs.

1.06 Most metering pumps are made to deliver a variable amount of fluid within a specific range or volume. Usually, the pumps variable pumping rate is between 5 and 10 to 1 (5:1 to 10:1), although some styles are made with 100 to 1 (100:1) ratios. In addition, the manufacturers generally offer several different sizes of the same pump in order to meet different flow rates. For example, a pump might have a variable capacity from 0.1 gph (gallons per hour) to 1 gph (10:1 ratio). However, if the application required a pump with a capacity of 2 gph, the manufacturer would provide a larger size of the same pump, or one with more than one pumping head.

1.07 The variable capacity of a metering pump is accomplished by one of two methods. Either using a fixed capacity pump with a variable speed motor/drive arrangement, or by using a fixed speed motor/drive arrangement and an adjustable capacity pump. In addition, some pump drives are controlled by signals from flow meters or concentration level sensors or analyzers. These will be explained in more detail in the following paragraphs.

1.08 Although, both methods produce the same end result, the maintenance requirements of each are different. However, it is important to check the fluid discharge rate each time an adjustment is made to the pump. This is necessary because there is a slight decline in the amount of fluid dispensed at the beginning and end of the pump stroke.

TABLE 1.1 METERING PUMP COMPARISON CHART

TYPE | MAXIMUM DISCHARGE PRESSURE (psi) | FLOW RANGE (GPH) | MAINTENANCE REQUIREMENTS |

Plunger | 1000 | .03–75 | check valves packing adjustment drive lubrication |

Diaphragm | 1 800 | .004 − 180 | check valves diaphragm replacement drive lubrication |

Bellows | 60 | .5 − 120 | check valves bellows replacment drive lubrication |

Rotary | 4000 | .03 − 10 | seals/gaskets drive lubrication |

Peristaltic | 25 | .0005 − 35 | tubing driven lubrication |

1.09 Other things to consider in the selection of a pump are its suction lift and discharge pressure capacities. (Note: suction and discharge heads are discussed in Volume 1, Chapter 12, paragraphs 12.04 to 12.14.) Because metering pumps are positive displacement style pumps, they can lift the fluid 15 or more feet without any problem. Also, they are capable of delivering the fluid at very high pressures, sometimes over 2,000 pounds per square inch (psi). Because the delivery pressure and the pump capacity do not always follow the same rules or pattern, it is very important to check the manufacturers literature before selecting a metering pump.

1.10 One additional item that must be taken into account when selecting a metering pump is the environment or location where it will be placed. Metering pumps are precision made devices and are not made to take a lot of physical abuse, and should be located where they are not subjected to chemical spills, heat, cold, or falling objects. They must also be accessible for routine maintenance, inspections, and periodic cleaning. A removeable cover placed over the unit will provide additional protection. A brief comparison of chemical metering pumps is shown in Table 1.1.

PLUNGER METERING PUMPS

1.11 Positive displacement metering pumps of the plunger (or piston) style are used in many applications. It is a simple, easily controlled or adjusted pump that delivers low to high flows (0.3 to 75 gph), at pressures up to and above 1,000 psi. The assembly consists of an electric motor drive, a worm gear reducer, a motion converter (crank), crosshead guide/connecting rod, and the liquid end (Figure 1.1). The liquid end is not only the housing for the plunger, but it also provides space for a packing gland (usually of the chevron type), a packing gland adjusting nut, lubrication fittings, and inlet and discharge valves.

1.12 The amount of fluid that can be pumped is determined by the plunger diameter, length of stroke, and number of strokes per minute. However, the most common method of changing the rate of flow is to change the length of the plunger stoke. Each manufacturer uses a slightly different technique, but the most common is to have some sort of an adjustable crank to which the connecting rod is attached. Moving the connecting rod up or down on the crank shortens or lengthens the plunger stroke. Other manufacturers use an adjustable connecting rod, tilting plate, eccentric, or an angled slot on the crank to change the stroke length. Whatever the style, the result is the same.

1.13 The liquid end of the pump (Figure 1.2), is probably of the most concern for both operation and maintenance. The packing gland of a metering pump, unlike a centrifugal pump packing gland, should not allow any leakage to occur. To accomplish this the packing gland, in most cases, contains a lubrication fitting. Some manufacturers use a seal flushing connection. The lubricant prevents the packing from scoring the plunger and also acts as a sealant. However, the amount of pressure on the packing must only be enough to seal fluid leakage. Overtightening of the gland will result in scoring and premature wear of the plunger.

1.14 The suction and discharge valves generally are of the ball style and are often spring loaded to aid in closure. However, some valves are of the flat disc or cone type. In addition, many manufacturers also provide a double check valve arrangement for more positive control of the fluid being pumped instead of only a single check valve. Check valves and seats are usually made of stainless steel, but other non-metallic materials are used when the discharge pressures are not excessive.

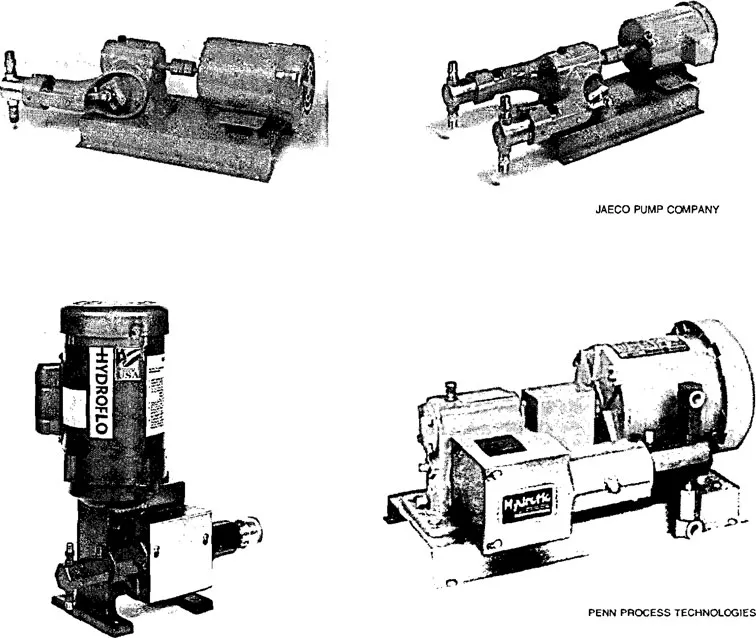

Figure 1.1. Plunger Metering Pumps

1.15 During operation, the inward travel or suction stroke of the plunger creates a vacuum or negative pressure within the pumping chamber (Figure 1.2). The negative pressure permits the discharge valve to close and opens the suction (inlet) valve. At the same time, fluid is drawn into the pump chamber until the plunger reaches the end of its travel.

1.16 As the plunger starts its forward travel (discharge stroke), it increases the fluid pressure in the pump chamber forcing the inlet valve to close and opens the discharge valve. With the discharge valve open the remaining fluid in the pump chamber is discharged into the system. The length of the stroke multiplied by the area of the plunger determines the volume of the fluid that is pumped. However, remember that there is a small amount of fluid that is not pumped at the beginning and end of each stroke. It is therefore important to check the volume whenever adustments are made to the plunger stroke.

1.17 Ensuring that the check valves are functioning properly is a priority maintenance requirement. Many manufacturers place the check valves in clear plastic housings that permit visual observation of the inlet and discharge valves. Pumps that have metal housings must be periodically monitored to ensure that they are delivering the proper amount of fluid. Often, the operator can tell when the pump is not delivering enough fluid by changes in the process reaction. However, an alternate method is to test pump some of the fluid into a measured container for a specific amount of time...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Preface

- Acknowledgments

- Abbreviations

- 1. POSITIVE DISPLACEMENT PUMPS

- 2. CONTROL VALVES

- 3. SCREENING EQUIPMENT

- 4. MIXING EQUIPMENT

- 5. AERATION EQUIPMENT

- 6. DISINFECTION EQUIPMENT

- 7. FLOW MEASUREMENT

- 8. INSTRUMENTATION

- 9. CORROSION CONTROL

- 10. SAFETY

- 11. EQUIPMENT INSTALLATION AND TROUBLESHOOTING

- Index