- 213 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Hands On Water and Wastewater Equipment Maintenance, Volume I

About this book

Hands-On Maintenance for Water/Wastewater Equipment deals with equipment maintenance as individual components, not as complete machines. This allows more information about the design, application and maintenance requirements of machinery to be presented. The text covers basic operating characteristics of machinery components, making it a valuable reference source as well as a training and maintenance manual. Written in easy-to-understand language, without complex formulas or technical theories, this text provides you with basic information to help you acquire a general understanding of how components function and how to keep equipment operating properly.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Hands On Water and Wastewater Equipment Maintenance, Volume I by Barbara Renner in PDF and/or ePUB format, as well as other popular books in Tecnología e ingeniería & Gestión medioambiental. We have over one million books available in our catalogue for you to explore.

Information

Subtopic

Gestión medioambientalCHAPTER 1

Introduction to Maintenance

THE NEED FOR MAINTENANCE

1.01 Maintenance is a part of everyday life, although little thought is given to some of the more routine “chores,” such as car and home repairs, lawn and shubbery care, painting, and many other items. However, even though these chores are considered the preservation of property or equipment, they are a form of maintenance. And when you look at the bottom line, maintenance really is the preservation of property.

1.02 The importance of water/wastewater plant maintenance has been discussed and written about for many years. It is a well-known fact that many plants suffer severe operating problems because of poor maintenance. When the topic is discussed, much attention is given to maintenance concepts and the overall program, but the basic fundamentals and details are overlooked or ignored. Following good basic maintenance procedures is like keeping your vehicle filled with fuel. Without fuel the vehicle will stop. Without proper maintenance, the equipment and your plant will shut down.

1.03 The maintenance program for water/wastewater plants should include not only the items that make the plant run efficiently but look good as well. Your plant is often judged by its appearance and not by how you treat the water. Maintenance procedures should be given a high priority in the daily work schedule, because making sure that the plant equipment functions properly is an important factor in achieving the proper water discharge quality. If the equipment does not operate properly, water quality standards cannot be met.

1.04 The need for a good maintenance program and the knowledge of how each component functions and should be maintained cannot be emphasized enough. By properly maintaining plant equipment, an operator can extend its operating life by at least 25 percent. The extended equipment life means less capital replacement expenses, better plant operation, and even better public relations. It should be a source of pride for both the employees and management.

THE KEYS TO GOOD MAINTENANCE

1.05 The performance of maintenance duties or tasks is only a small part of the maintenance function. Although it is important that you understand how to repair a piece of equipment, it is also important that you understand how the component performs its operation as well as some of its design, engineering, and construction features. Understanding the more “technical” aspects of various equipment components should help you gain knowledge of why breakdowns and failures occur. This extra knowledge should help you improve your maintenance program, increase equipment life, and make your job easier.

1.06 Waste or wastewater operators are usually very professional in the manner in which they run their plants. Setting up a maintenance program and performing routine maintenance are just other steps in operating the plant. There is nothing special that is required to set up a maintenance program or to see that the one you have works well. If you do not have the time to develop your own program, there are a number of “packaged” programs available, including manual and computer-driven types. Chapter 2 explains more on establishing a maintenance program.

SCOPE OF THE MAINTENANCE PROGRAM

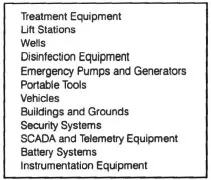

1.07 All water or wastewater plants have different maintenance requirements. Location, size, staff, and funding all determine how a maintenance program should be set up. Although many design engineers recommend maintenance procedures, only plant personnel can determine what sort of program best suits their individual needs. However, to be effective and efficient, the program should be all-inclusive and not be limited to only the major plant components. The items listed in Figure 1.1 should be used as a guide to establishing a complete maintenance program.

1.08 You must consider not only how broad your mainte nance program will be but also who is going to perform all of the work. For many plants, the maintenance functions, including landscaping, vehicles, water drainage or retention, buildings, and/or storage facilities, are within the scope of the plant staff. For other facilities only the internal equipment or machinery is all the staff maintains, whereas small operations with limited staff may perform only limited or even no maintenance on their equipment. In fact, equipment maintenance is performed by outside contractors or vendors for some small utilities. The important key is to make sure that a maintenance program exists. If your maintenance work is performed under contract by an outside source or by personnel from different utility divisions, make sure that you have input into the maintenance program.

Figure 1.1. Partial list of items that require maintenance

1.09 Whatever approach you use to establish your maintenance program, make sure that it is “flexible” and can accommodate all of your needs while you still can accomplish your other necessary work. Maintenance frequency should be adjusted periodically on the basis of operating or running time and seasonal conditions. For example, if a pump runs only a few months a year, the maintenance frequency cycle should be extended to accommodate this, as opposed to a pump that runs 24 hours a day for weeks on end. Using hours of operation instead of calendar time has always proved to be the most efficient method of scheduling maintenance.

1.10 If you purchase a “packaged” maintenance program (card file, bulletin board, software, etc.), make sure that it is “operator-friendly” and can be modified or adjusted to your specific application or situation. A program that has a lot of options but cannot be modified has limited effectiveness and causes more problems than it solves. Generally, most “packaged” maintenance programs are computer-type programs. Although these programs are helpful, they often require someone to put in and retrieve data. They also generate a lot of paper, some of which can be helpful when properly used. For medium or large utilities, this could mean the hiring of additional administrative staff or assigning one person to run the program. For small utilities, it can take away from performing other duties.

1.11 If you have recently been employed by a utility that has an existing program and you have to make sure that the maintenance is performed, take a good look at the program rather than accept what presently exists. Many times, plant conditions change or have been modified. Under these conditions, the level of maintenance must also change to accommodate different equipment.

CHAPTER 2

Establishing a Maintenance Program

APPROACH TO PLANT MAINTENANCE

2.01 As you know, some sort of maintenance must be carried out to keep a plant functioning smoothly and in good repair. The approaches to plant maintenance vary from total neglect, to emergency repairs only, through minor lubrication, up to computer-driven fully operational programs. Unfortunately, the operators who believe they are saving money by not performing maintenance really pay more for repairs when the equipment finally breaks down.

2.02 Many plant personnel think that maintenance requires a complex program and a lot of involvement and time. However, all that is required for a smooth running maintenance program is that the operator keep an eye on the daily operations of his equipment and perform the necessary maintenance tasks on a routine schedule. Maintenance tasks range from simple lubrication, to minor adjustments, to complete overhaul, depending on the piece of equipment and the situation. The important thing, however, is to perform some sort of maintenance on a regular basis as determined by the plant personnel and the equipment manufacturer. This may sound overly simple, but regularly performed maintenance becomes a normal way of running the plant and requires little or no extra effort.

2.03 Painting, housekeeping, landscaping, building repairs, and even vehicle upkeep are all forms of plant maintenance. They are no less important than equipment maintenance, because these items are what the public sees and judges your performance on. However, this book primarily deals with equipment maintenance. Maintenance of the buildings, grounds, and vehicle maintenance is left up to you.

TYPES OF MAINTENANCE

2.04 There are many words used to describe equipment maintenance. The newest and latest are proactive and predictive maintenance. Proactive, in most instances, only refers to setting up and implementing an active maintenance program. Predictive maintenance, on the other hand, deals primarily with planning or scheduling maintenance around operating time and the expected life of a piece of equipment. Because of the adverse conditions in which water or wastewater plants operate, the more flexible and proper terms used to describe equipment maintenance are:

• breakdown maintenance

• preventive maintenance

Most of this chapter will be directed to preventive maintenance, because this is the best way to control breakdown maintenance.

2.05 It should be acknowledged that some amount of breakdown maintenance will take place at any plant. Even plants that have a strong preventive maintenance program always have the possibility that something will go wrong and that equipment will unexpectedly break down. However, a good preventive maintenance program will keep the number of breakdowns to small or infrequent occurrences that will not affect the plant operation.

2.06 Even equipment breakdowns can be handled as a nonemergency if you do some preplanning and maintain spare parts and other needed items. Preplanning in the form of maintenance instructions and alternate plans for operating are as important as spare parts. Having an emergency operating plan and spare parts will save you from making a lot of telephone calls or doing a lot of unnecessary chasing around looking for equipment components on short notice.

2.07 There are many situations where manufacturers do not maintain a stock of all spare parts (especially noncritical parts), necessary to keep their equipment running. In these situations, critical parts would have to be manufactured from “scratch,” necessitating the shutdown of the affected piece of equipment until the parts are available. In some cases, this lack of spare parts could force you to shut down the entire plant. All of this can be avoided with a small amount of timely preplanning.

2.08 Preventive maintenance, on the other hand, relates to the scheduling and performing of regular maintenance functions from inspections through overhaul or replacement. It also should be considered a part of your normal daily work routine and something that is necessary to keep the plant operating at full capacity. In almost all plants, especially the smaller ones, preventive maintenance is in the form of inspections and tests that are performed every day. Preventive maintenance can further be broken down into two categories:

• planned maintenance

• routine maintenance

2.09 Planned maintenance is defined as the periodic scheduled removal of equipment from service for the disassembly and inspection of the internal working parts. This periodic inspection provides you with a visual look at the physical condition of the individual components and should alert you to any potential major equipment problems caused by normal or abnormal wear. Planned maintenance is most beneficial because it permits you to evaluate the life of the equipment and plan overhaul or reconditioning intervals.

2.10 Routine maintenance, on the other hand, is best described as the daily general inspections and tests, including regular lubrication, that are performed as a part of the regular operation of the plant. The daily routine and checking of the plant equipment will make you more aware of minor problems that occur and permit you to make corrections and adjustments necessary to prevent a major breakdown or other costly repairs.

ESTABLISHING A PREVENTIVE MAINTENANCE PROGRAM

2.11 There are several methods used to establish a total preventive maintenance program. Any program should include the frequency of planned maintenance, the amount of routine maintenance to be accomplished on a daily, weekly, or monthly basis, and allowances for emergency repairs. The amount of planning required to set up ...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Preface

- Acknowledgments

- List of Abbreviations

- 1. INTRODUCTION TO MAINTENANCE

- 2. ESTABLISHING A MAINTENANCE PROGRAM

- 3. LUBRICATION

- 4. BEARINGS

- 5. D-C AND SINGLE-PHASE MOTORS

- 6. THREE-PHASE MOTORS

- 7. THREE-PHASE MOTOR CONTROLS

- 8. VARIABLE SPEED DRIVES

- 9. COUPLINGS

- 10. BELT AND CHAIN DRIVES

- 11. SEALS AND PACKING

- 12. CENTRIFUGAL PUMPS

- 13. GEARS AND REDUCERS

- Index