![]()

1 Costing Basics

Costing garments is a function performed by many fashion professionals and at various times throughout a style’s development. More than just calculating what a garment will cost, costing assists in fine-tuning a style specifically for a particular target customer or price.

The Role of Costing

Depending on the size of the company, costing is performed by many different individuals and departments. In a small company, the costing may be done by the owner or the designer. Costing is often performed by the production manager or merchandiser in a mid-sized company.

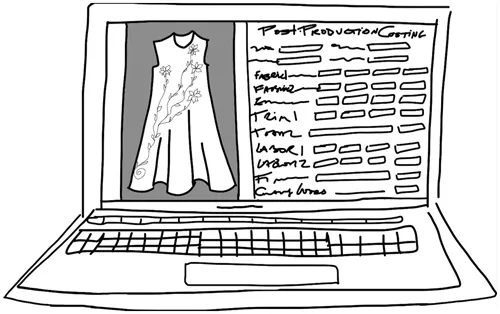

In a large company, the costing may be performed by the product or wholesale manager. Lastly, in a very large firm, there is an actual costing manager position. Smaller companies will often utilize Excel or another spreadsheet application to calculate their costing, while in larger firms, costing is performed within their Product Lifecycle Management (PLM) software. PLM software manages the information of a style through design, development, material procurement, production and distribution process. Larger companies will use PLM or another similar software system. For this workbook, however, all costing will be explained and calculated manually. In order for a fashion professional to cost with PLM or any other software, they must first understand the numbers, how to calculate them, and the thought processes of good costing. No matter who (owner, designer, product or costing manager) is performing the costing and how (manually, Excel, or PLM) cost sheets are completed, costing garments requires outstanding analytical skills, a precise attention to detail, and an ability to negotiate. These skills are utilized during the development, production, and completion stages of each style, as at each of these times during garment-making we engage in costing. In this workbook, we will refer to these separate, but interconnected, stages in which we cost as the “costing timeline.”

The Costing Timeline

Costing, when done correctly, is calculated before, during, and after a style is produced. Costing throughout the stages of production eliminates the time and money spent producing additional samples of styles that cost out too high early on in the development phase.

Many new designers cost garments after their samples have been approved. It makes more sense for them to look at their cost sheets when first evaluating a sample, as end-costing is not cost-effective if time and money went into perfecting a style, in which the cost is far greater than the target. Therefore, costing early, and costing late as well, are just as essential as costing during the production stage. The three stages of costing are: pre-production, production, and post-production costing. Let’s look at all three.

Pre-Production Costing

Pre-production costing, also referred to as sample costing, pre-costing, cost estimating, and/or predictive costing, is a preliminary estimate of costs. Pre-production costing should be calculated with the first sample, as well as with each subsequent and revised sample. This costing is based on the estimated cost of fabric and trims used to create each sample, as well as on the estimate for production labor. Other cost factors (such as shipping and duties, if applicable) are estimated based on current rates. Pre-production costing is calculated with an estimated quantity, for example, how many of a style do we think we will manufacture and sell?

The advantages of pre-production costing are that as soon as you receive a sample you have a ballpark measure of what a style costs the company to make, if the style is adopted for production. This will help you evaluate the style in terms of whether or not it can work for your line. At times, pre-production costing is calculated before a sample is created, and allows a manufacturer to know whether it is worth cutting and sewing or knitting a sample at all.

Pre-production costing allows a company to determine:

• What a style will most likely cost if adopted;

• If a style can be produced at the target cost;

• And, if not, how a style can be changed so that it can lower cost by determining what is/are the largest cost factor(s) of the style, such as styling, fabric, trim, dyeing or surface treatment, labor, or transportation costs.

With this knowledge, you can proceed as is, or revise the sample so that you can reduce the quantity, complexity, or time of whichever line item is highest to bring the cost down if needed.

Pre-Production Costing Example

Let’s assume we are developing a style for a Victorian-themed shirt group for the fall season. In Fig. 1.1 we see a flounce-front, long-sleeve shirt with French cuffs.

Fig. 1.1 Flounce-front shirt with French cuffs.

You create a set of pages with information and detailed specifications for the styles known as a technical package or tech pack for short. You send the tech pack to your overseas factory, and a silk sample is returned with pre-production costing of $21.79 per piece (Table 1.1). If you are a manufacturer who has a target cost of $18–$19 (not including duty and clearance), you will know immediately upon receiving your sample that you need to make some changes to your style, or reduce your profit greatly. It is too soon to reduce your profit, as this is just a preliminary cost sheet and all costs are estimated, and there are no indirect costs present yet.

You will need to evaluate both the sample and the preliminary cost sheet during this pre-production costing stage. You need to decrease the costs per unit by approximately $2.80 to $3.80 in order to produce this style at your target cost. The target cost is the expected and maximum allowable total cost of a garment/product based on a selling price you believe your customer will pay. As your cost is too high, you need to evaluate what changes can be made to the style to hit your target cost range. We see in the preliminary cost sheet that the highest cost factor is fabric. Therefore, we must analyze ways to reduce fabric costs.

Possible Solutions for Reducing Fabric Costs

• Switch style to a lighter-weight silk crepe quality

• Reduce fabric yield by either shortening or narrowing flounce front or revising pattern to a standard cuff instead of French-cuff style or shortening blouse length

• Switch to a silk-blend fabric

• Go back to the textile mill/agent and try to negotiate a lower fabric price

The next highest cost factor is labor. Style detail and finishing changes can be made to reduce the sewing time or complexity, which would reduce labor.

Possible Solutions for Reducing Labor Costs

• Omit topstitching on collar, cuffs and/or darts

• Omit the front and back darts

Table 1.1 Preliminary cost sheet for flounce-front shirt with French cuffs

Fig. 1.2 Flounce-front shirt with standard cuffs. Note the flounce is slightly decreased in width, topstitching omitted and cuffs have been revised.

Change the hem on the front flounce to a coverstitch, instead of a rolled-hem.

These are examples of areas to cut costs early on in design development. A new cost sheet must be generated with every sample created so the designer and manufacturer can understand and know if it makes sense to manufacture and sell a particular style. Another sample for the Victorian-inspired blouse would then be ordered with the revisions to bring down the costs (in order to meet the target cost of $18–$19). After sending comments to shorten front and back lengths by ¾ inch (19 mm), changing to a standard cuff, and shortening the flounce by 2 inch (51 mm)—all which reduce fabric yield—eliminating topstitching at collar and darts, and switching to a slightly lighter-weight fabric, the sketch and tech pack is revised and another sample is created (Fig. 1.2). This revised sample is within the target cost range and has a pre-production costing of $18.79 per piece (not including duty and clearance) as seen in the new cost sheet (Table 1.2).

Often it takes more than two revisions to get to the target cost, but regardless of the number of cost sheets, it requires good costing skills, exercised early on and throughout the sample development process, and those skills must be applied to every line item. If yet more samples are requested for the Victorian-themed example, a preliminary cost sheet would accompany each sample. A style’s cost changes with each and every change in that style’s pattern, construction, fabrication, and trimming.

Once a style is approved for production, we move along to the production costing phase.

Production Costing

Moving along the costing timeline, we travel from the development to the production stage of each style and calculate the final production cost. Although it is a final cost, it is important to understand that costing at this stage is still an estimate; a final cost estimate. Not until production and shipping is completed, will we truly know how much it cost to produce the style.

Table 1.2 Revised cost sheet for flounce-front shirt with styl...