- 162 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Get Qualified: Inspection and Testing

About this book

The Get Qualified series provides clear and concise guidance for people looking to work within the electrical industry. This book outlines why the inspection and testing of electrical installations is important, and what qualifications are required in order to test, inspect and certify. All you need to know about the subject of inspection is covered in detail, making this book the ideal guide for those who are new to the subject and experienced professionals alike. There are also sections on exam preparation, revision exercises and sample questions.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Part 1

CHAPTER 1

Introduction

It is a fundamental principle of the IET Wiring Regulations (BS 7671) that all electrical installations must meet two basic criteria: first, they must be safe and, second, they must perform their intended function, i.e. they must work. In the early days of electrical installations this was simple to achieve, because electrical installations were very simple in nature and safety requirements very basic by today’s standards.

Later, as the electrical industry grew, most electrical installation work was carried out by local electricity boards using time-served tradesmen, who were not hurried by the time and cost pressures experienced by modern electrical contractors. As a result, most installation work was performed to a high standard and therefore the checks carried out on this work were minimal.

Fast forward to today and we see modern, highly complicated electrical installations, installed very quickly using teams of installers, many of whom will not be time-served electricians. Add to this the increasing demands placed upon us to improve health and safety and the growing culture of claims and litigation. It is therefore essential in the modern world that the safety and correct functioning of electrical installations is not just taken for granted, but is thoroughly proven by a rigorous process of inspection and testing. Out of this basic need has grown the art of inspection and testing, the subject on which this book is based.

Inspection and testing has now become an integral part of the work carried out by all electricians. A test meter and a pad of certificates are now as important to an electrician’s daily work as are his or her screwdrivers, wire cutters and SDS drill. While inspection and testing has long been a requirement of the IET Wiring Regulations (BS 7671), widespread adoption of inspection and testing throughout the industry has only occurred due to the hard work of trade organisations such as NICEIC and others. The addition of electrical safety into the Building Regulations (Part P) in 2005 made a huge difference to the amount of inspection and testing performed within domestic installations, which had long been a part of the industry dominated by DIY and cowboy electricians.

There are, however, sectors of the industry still slow to fully embrace inspection and testing; from my experience one notable example being maintenance electricians in production or factory environments, where it is common to see electrical repairs carried out without any inspection, testing or certification. It is key to improving safety within the electrical industry that the practices of inspection and testing are adopted by all sectors across the industry and that the importance of inspection and testing is understood by all.

In this book I aim to simplify this subject and introduce you to each topic in a straightforward and common-sense way. I will look at what is required to meet your legal obligations and explain the options you have to ‘Get Qualified’ and undertake inspection and testing in your own right. Throughout the book I will make frequent reference to statutory documents, like the Electricity at Work Regulations 1989 and to other guidance documents, such as the IET Wiring Regulations (BS 7671) and IET Guidance Note 3. A list of these documents can be found in Chapter 7, ‘Information required for inspection and testing’. Many documents are available as free downloads and I would strongly suggest you use them as an accompaniment while you read the rest of this book.

The ability to undertake inspection and testing is not rocket science and is easily within the reach of most electricians. With the right training and experience you will very soon be performing this task quickly and efficiently. You will also have the added peace of mind that this important safety task has been done correctly and in accordance with current industry best practice.

CHAPTER 2

What is inspection and testing?

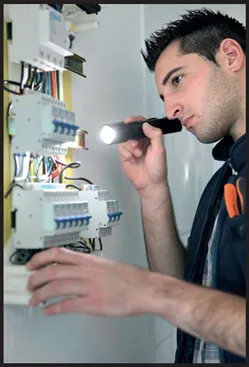

It may appear obvious to say that the subject of this book ‘inspection and testing’ is made up of two activities, ‘inspection’ and ‘testing’. Inspection involves using your senses – sight, touch, hearing, etc. – to inspect an electrical installation. Testing is the process of using a meter to take measurements. Always be mindful, when discussing the subject of ‘inspection and testing’, to consider these two activities separately as they both contribute in different ways to our knowledge of the electrical installation.

The aim of the inspection and testing process is to establish the safety and correct functioning of the electrical installation, without posing a danger to the inspector or other persons and without damaging the electrical installation under test.

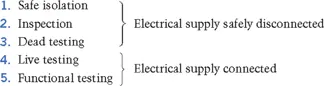

To meet this basic and essential aim, the inspection and testing process for new installations usually follows the format detailed below:

The aim of the above process is to gradually, step-by-step, prove the safety of the electrical installation in the safest way possible. Only when the installation successfully passes one stage within the process, is it then safe to proceed to the next step. It is essential that inspection and testing are carried out throughout the installation process and on completion. It is not possible to carry out full inspection and testing on a completed installation, as much of the installation may be hidden within the fabric of the building and we may not be able to carry out a full range of tests with all circuit loads connected. Many electricians make the mistake of believing that inspection and testing is something done at the end of a job, as a type of final sign-off procedure. It is not possible, for the reasons stated above, to fully inspect and test completed installations, and attempting to perform inspection and testing in this way is both incorrect and inefficient.

TYPES OF INSPECTION AND TESTING

There are two main types of inspection and testing referred to in the IET Wiring Regulations (BS 7671). The first is initial verification, the inspection and testing of new installations, alterations or additions. The second is periodic inspection, performed on existing installations.

Initial verification

A new electrical installation, prior to initial verification, has never been connected to its supply or performed its intended function before. It is possible therefore that this new installation may contain defects introduced during the installation process, which must be identified and corrected before the installation is put into service. All new installations must comply with the current edition of the IET Wiring Regulations (BS 7671); this compliance must also be confirmed at this stage. The initial verification of new electrical installations is essential, as any issues not detected at this stage are likely to remain undetected for many years and could pose a hidden danger to the safety of those using the installation in the future. The initial verification process is also applied to additions and alterations to an existing electrical installation. These additions or alterations may include, for example, the addition of a new shower circuit, the alteration of an existing socket circuit to include more socket outlets or even the repair or replacement of a faulty luminaire. In each example the purpose of initial verification is the same: to prove the safety of the new installation or equipment and ensure compliance with the regulations.

Periodic inspection

As electrical installations age, some damage or deterioration is inevitable. The requirements of the IET Wiring Regulations are also being constantly updated, making many older installations appear obsolete by modern standards. The purpose of a periodic inspection is to ensure that an existing electrical installation is safe for continued use. By its very nature a periodic inspection is much more difficult and nuanced to carry out than the very black-and-white initial verification process. Electrical installations receiving a periodic inspection will not be in ‘as new’ condition and are unlikely to fully comply with the latest edition of the wiring regulations. A greater degree of judgement is therefore required from the inspector, who must consider additional factors such as context, rates of deterioration and other evidence before making final recommendations to the customer.

CHAPTER 3

Who can carry out inspection and testing?

This question is often the subject of much confusion, so in this chapter I will attempt to simplify the requirements and help you to finally get an answer to the question above.

Unfortunately, the confusion around this subject is e...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Part 1

- Part 2

- Part 3

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Get Qualified: Inspection and Testing by Kevin Smith in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Civil Engineering. We have over one million books available in our catalogue for you to explore.