1.1 INTRODUCTION

Strategic Excellence is a goal and a process. Excellence is a moving target. Like airbags in cars, what was considered above and beyond normal and a level of excellence 10 years ago is routine today. The goal of Strategic Excellence is a moving target and needs to be reviewed at least annually.

Strategic Excellence is also a process in that it requires a focus on continuous improvement. Strategic excellence is applied strategic thinking designed to develop an empowered agile strategy that adapts to changing circumstances and drives a high performing culture of striving towards ideal behaviors. It is infused with the insight and the thought leadership of the Shingo Model and the scientific thinking of Lean Six Sigma, as derived from the Toyota Production System (TPS). Strategic Excellence goes beyond the classic approach to strategic planning by driving effective execution of the strategy by embedding collective ownership and organization-wide alignment into the entire process.

Reflecting on TPS, Toyota Engineering’s approach is extremely different from the American automakers, such as Ford or General Motors. When Toyota engineers a new automobile, it generally takes less than 6 months. When the American auto manufacturer engineers a new vehicle model, it generally takes over 3 years, although they are now trying to gradually improve the process. There are numerous examples of how this process is manifested. One quick example can be found in the airbag. The airbag was an invention by American automakers, but Toyota was the first to install airbags in their automobiles.

So, what’s the difference between Toyota and General Motors or Ford? Toyota manufacturers focus on quality. For example, if they design a hinge for a car door, and they find that the hinge has high quality, high reliability, product consistency, etc., they will use that same hinge in all of their vehicles. In contrast, when American auto manufacturers design a new vehicle, they reengineer everything, right down to the door hinges. The result is twofold: (1) American engineers take a lot longer to engineer a car and (2) American cars have hundreds of times as many recalls as cars manufactured by Toyota. However, when Toyota has a recall, it’s large because it affects a large number of vehicle models.

To compare Toyota and the American manufacturers, let’s consider the effect of the different methodologies. Which is more customer responsive by having a higher level of product flexibility? Which methodology tends to have higher quality and reliability? What characteristics do you, the reader, prefer in the products that you purchase? Which of these two engineering strategies would you classify as having strategic excellence?

Strategic excellence is not an accident. It doesn’t happen by chance. It requires intelligent planning and deliberate action. Strategic excellence is the prerequisite for achieving a corporate vision. It is the only path to victory.

On June 6, 1944, the Allied forces crashed onto the beaches of Normandy. The D-Day campaign involved more than 13,000 aircraft, 5,000 ships, and 150,000 troops from eight different Allied countries. The Allied forces had been working together for many months in preparation for that day by spreading out Nazi forces using a variety of tactics. Despite the unprecedented amount of coordination required to execute an operation of this size, when the smoke cleared, the Allied forces had established a solid foothold in Europe. This extraordinary victory was referred to by Winston Churchill as “the beginning of the end.”

Dwight D. Eisenhower stated that “in preparing for battle I have always found that plans are useless, but planning is indispensable”. When the Allied forces landed on the beaches, chaos ensued. Surely, many aspects of the invasion didn’t go exactly as planned. However, the many months of planning had prepared the Allied forces to succeed, no matter what scenario they were challenged with when they hit the beach.

The message of this story is that it’s the process of strategic planning, the analysis of the options, and the consideration of alternative scenarios which is invaluable. The resulting plan will invariably change because the environment and the assumptions change. For example, the weather changes, the people change, the financial structure changes, the legal structure and the code structure change, and so on. The better you have thought through the various potential scenarios, the better prepared you are for the unexpected.

This book takes the “planning is indispensable” approach to strategic excellence. The planning process presented here will unite an organization behind a shared mission that will guide and direct decision making and problem solving at all levels. It will develop a culture that will prepare your organization to succeed, despite the scenario encountered.

1.2 PHASES

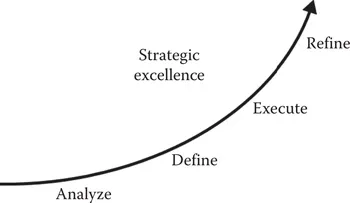

This book explores the Strategic Planning and Strategic Management processes by categorizing them into four functional phases. Strategic Planning is divided into two phases, which are thoroughly analyze the current and future conditions and then define a competitive strategic plan based on the analysis. These first two phases that we are grouping together as Strategic Planning are also often referred to as SA&D (Strategic Analysis and Design).

The second two phases are lumped together under the heading of Strategic Management. These phases are to execute the plan in an effective manner that will align the entire organization focused on the plan and then refine the plan over time, learning from our experiences to maintain a focus on continuous improvement (Chart 1.1).

1.2.1 Analyze

A successful planning process is built on a foundation involving a thorough understanding of current conditions. Far too often, engineering becomes an exercise in what is referred to as Catalog Engineering. For example, Catalog Engineering frequently occurs when companies lay out their assembly lines. They search the catalogs put out by industrial machinery makers and they create some combination of different machines using machines that already exist, trying their best to make them work together successfully. Often, the job of making the pieces work together becomes someone else’s problem, like production.

At Toyota, the engineer’s job is not completed until he or she incorporates creativity into the newly created line. His or her job is to make the line better than the sum of its parts. The Analyze Phase defines the end product to be high quality and error-free. The engineer’s job isn’t finished until after the trial runs are completed and the assembly line is in full production, running with high quality and error-free. An example of how this works is that the production line must be sensitive enough to failures so that it stops itself automatically. No bad product should ever be produced. The Analyze Phase includes the requirement that the engineer must stay with the assembly line and continue refining the line until he/she achieves the goal of being error- and defect-free.

The Analyze Phase of this book explains the elements of both an internal analysis and an external analysis. Useful tools for ensuring a thorough analysis are presented and their usage is explained. The analysis process works to break through the cultural façade and identify the underlying issues that are typically overlooked. It forces the organization to ask the hard questions that many organizations subconsciously avoid asking themselves. Starting with a detailed analysis of the current state of the organization and the environment in which it operates and recognizing the gaps between the current state and the desired state will lead the organization towards developing a highly competitive strategy.

1.2.2 Define

Defining a strategic plan is often simplified by downloading a free template or slightly altering a previously used plan. This approach not only results in an uncustomized strategic plan but also completely misses out on the true power of strategic planning, which is the planning process itself. The methodology presented in this book will result in a highly competitive plan, customized for the specific strengths and needs of the organization. Additionally, it creates organizational buy-in. This means that the defined strategy is not only important to one person who tries in vain to execute it, but it becomes a shared vision that stimulates a sense of strategy ownership infused throughout the entire organization. The process of defining the strategy presented in this book will result in a plan that is primed to be successfully executed.

In the authors’ experience as a consultant for organizations that have achieved enterprise excellence, it is common to walk around an organization and randomly ask employees what the goal/vision/mission is of the organization they work for. In most companies, it is rare to find someone who is even willing to attempt to guess what the company’s vision is. But in Enterprise Excellent organizations, the employees know their organization’s goals and they incorporate them into their daily activities, ensuring that what they do has strategic alignment. Try it in your organization. Randomly ask employees what the corporate vision is and see what you learn from their responses.

1.2.3 Execute

Executing a strategic plan can often be a frustrating endeavor, similar to initiating the movement of a heavy stationary object. The resting object tends to remain at rest. Tradition and a feeling of “we’ve always done it that way” tend to dominate and resist change. Getting a strategic plan to the point where it begins to build momentum and continues moving in the right direction can take significant time and energy. The Execute process presented in this book builds on the momentum created during the Define phase. When the entire organization is aligned with the strategy and buy-in has been established, executing the plan becomes the natural next step because every member of the organization is working to move the strategy in the right direction. The Execute phase presented in this book takes advantage of this momentum by strengthening the organizational alignment with the strategy, building engagement, and establishing effective visual management. This phase works to employ the strategy in such a way that it will act as a guide to decision making and problem solving at all levels of the organization. This process allows managers and staff to overcome challenges in ways that will support the vision/mission/goals of the organization and keep the momentum going.

1.2.4 Refine

An effective strategy cannot be stagnant. It is a living entity with the ability to learn and change. The Refine phase causes an evolutionary adjustment to the strategic plan, giving it the inherent ability to analyze and respond to internal and external changes. It creates a culture of learning that perceives problems as opportunities and facilitates an organization-wide philosophy of continuous improvement. It establishes a continual loop of learning and improving that will propel your organization to the front of the pack and keep it there. The Refine phase presented in this book keeps the organization current and competitive.

At Mitsubishi, an experiment was conducted called a “Purpose Expansion.” Employees tracked all of their activities for a 2-week period. They recorded what they did and how much time they spent doing it. This exercise had to be prefaced with a corporate commitment that no employees would lose their jobs. After 2 weeks, the employees summarized their activities using a spreadsheet. In the second column of the spreadsheet, they were asked to indicate the purpose of each activity. In the third column of the spreadsheet, they were asked to indicate the purpose of the items listed in the second column of the spreadsheet. In the fourth column of the spreadsheet, they had to indicate if the purpose that they listed in the third column satisfied the vision/mission of the organization, which was to either (1) increase customer satisfaction or (2) increase quality. These two items were, of course, the strategic objectives of Mitsubishi. The fourth column allowed for three responses: (1) Yes, the purpose satisfied one of the strategic objectives, or (2) No, the purpose had no effect or possibly even detracted from the strategic objective, or (3) the employee wasn’t sure if the activity was supportive on or not. If the activity listed in the first column had a “NO” response in the fourth column, then the employee was to immediately cease doing that activity. The result was an almost exact one-third split between each of the three responses, which meant that one-third of the activities of the employees was stopped. These activities were considered to be a “waste” since they did not improve on the organization’s goals. This new free time was then allocated to spending more time on the one-third of the activities that had a “YES” response. Mitsubishi was able to refine and improve their process using this simple Purpose Expansion exercise. (For a detailed discussion of this experiment, refer to the book, Making Innovation Happen: Concept Management through Integration, Delray Beach, Florida, St. Lucie Press, by Gerhard Plenert and Shozo Hibino.)

1.3 SUMMARY

The authors have lost count of the number of times they have conducted an Enterprise Excellence seminar in a company and asked the attendees to write down the company’s vision or mission statements. The employees walk by the statements every day as they enter the building. They may even have been involved in the creation of these statements. But they don’t remember what they are. So, the next question that must be asked is, “Are the activities that you are doing daily, or is the job that you are doing, achieving the vision of the company if you don’t even know what it is?”

Significant advances in strategic planning and management have been developed over decades of learning and practice. However, many of those advances have been developed in the manufacturing industry and have not been translated into terms easily applicable to the AEC (Architectural, Engineering, and Construction) industry. This book incorporates the current best practices from cutting-edge organizations around the globe and presents those practices in a way that they can be applied easily, efficiently, and effectively to AEC organizations. This book applies proven Shingo and TPS Lean Six Sigma methods and tools to the strategic planning and management processes in a uniquely new methodology that the AEC industry has never seen.

The approach of this book is not just to develop a strategic plan, but to develop a strategic way a thinking. It’s a cultural approach to creating and maintaining a competitive edge. It challenges the status quo in order to advance beyond it. Shigeo Shingo said, “those who are not dissatisfied will never make any progress”. Strategic Excellence in the AEC industry will allow you and your organization to drastically reverse long-endured dissatisfaction and a lack of progress into exceptional forward surges.

2.1 INTRODUCTION

When Dr. Gerhard Plenert was traveling in Japan working with his co-author on a different book, he would often join in with a group of academics and Toyota executives to discuss Toyota Production System principles. One night, during one of these discussions, the conversation turned to the United States. One executive asked, “Do you want to know what’s wrong with the United States?” Unfortunately, this is a conversation that occurs far too often during international travels. Everyone seems to know what’s wrong with the United States and they are eager to share their insights on how to fix the issues.

Dr. Plenert was tempted to answer by saying, “No. But I can tell you what’s wrong with Japan.” Instead, he answered, “Tell me what you think is wrong with the U.S.”

The executive came back with a very Lean answer. He suggested, “You’re creating far too much non-value-added content.”

Dr. Plenert responded, “What does that mean?”

The executive drew a diagram on a piece of paper (see Chart 2.1) as he said, “Look at the students that you are graduating from your ...