- 254 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

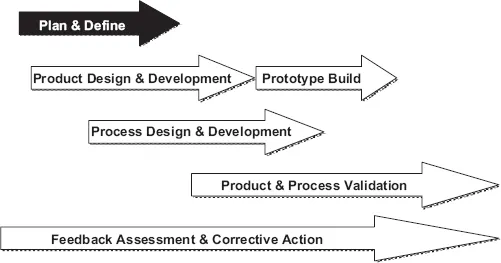

This book defines, develops, and examines the foundations of the APQP (Advanced Product Quality Planning) methodology. It explains in detail the five phases, and it relates its significance to national, international, and customer specific standards. It also includes additional information on the PPAP (Production Part Approval Process), Risk, Warranty, GD&T (Geometric Dimensioning and Tolerancing), and the role of leadership as they apply to the continual improvement process of any organization.

Features

- Defines and explains the five stages of APQP in detail

- Identifies and zeroes in on the critical steps of the APQP methodology

- Covers the issue of risk as it is defined in the ISO 9001, IATF 16949, the pending VDA, and the OEM requirements

- Presents the role of leadership and management in the APQP methodology

- Summarizes all of the change requirements of the IATF standard

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Advanced Product Quality Planning by D. H. Stamatis in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Industrial Design. We have over one million books available in our catalogue for you to explore.

Information

section one

The APQP process

chapter one

Plan and define

Perhaps one of the most important responsibilities of the entire advanced product quality planning (APQP) process is the plan and define stage. The essential responsibilities are:

Sourcing decision (SD)

In its most inherent responsibility it is “the” process that the customer uses to evaluate the supplier for future business. It serves as a formal customer commitment to work with all internal and external part suppliers, tooling suppliers, and facility suppliers on a program. Another way to describe it is that the SD is a coordinated effort between customers and suppliers for a “best fit” relationship to produce and accept the required product.

A critical evaluation of the potential supplier may be a source evaluation including a physical visit to the supplier’s facility. A typical source evaluation has five components. They are:

1. Identification: Here the following items are considered and evaluated: (a) review list of possible suppliers; (b) analyze suppliers with existing ratings or evaluations—sometimes this analysis is based on surrogate data; (c) screen supplier pre-evaluation data; and (d) determine strategic suppliers needing evaluations.

2. Task clarification: Here the following items are considered and evaluated: (a) clarify scope of tasks related to product, site, and technology and supplier performance data, which may be from past experience with the supplier and or surrogate data from similar products; and (b) prepare decision-making recommendation and obtain management approval for the task.

3. Visit preparation: Here the following items are considered and evaluated: (a) form the cross-functional and multidiscipline team, (b) hold kickoff meeting and assign roles and responsibilities, (c) preliminary discussion of supplier pre-evaluation package, and (d) schedule on-site visit and confirm trip details.

4. On-site visit: Here the following items are considered and evaluated: (a) perform on-site evaluation, (b) inspect facility, (c) collate and coordinate analysis results and scoring, and (d) conduct closing meeting with supplier with verbal feedback of major findings (good and bad observations).

5. Initial risk evaluation (IRE): Perhaps one of the most overlooked items in the planning phase is an IRE. But what is an IRE? In the simplest form it is an upfront evaluation (assessment) of the inherent risks in a new or modified part. This assessment may include: (a) historical performance (quality, capability, capacity, delivery, costs, safety, and manpower) availability; (b) available dedicated facilities; and (c) financial stability. (Here we must mention that the customer—depending on the status of the supplier—may require more than one IRE during the course of the program).

So, what are some of the key risk drivers that should be assessed? Typical items of concern are summarized in Table 1.1.

6. Results and reporting: Here the following items are considered and evaluated: (a) finalize summary report and defined criteria, (b) calculate the evaluation’s pass/fail rating and identify any risk factors, (c) report to approved managers, and (d) upload the information to the electronic system—if there is one.

At the end of this evaluation the key expectations are:

• All internal and external suppliers for a program are identified.

• Early sourcing target agreements are established and signed by appropriate areas.

• All nonspecific customer requirement (e.g., Q1 3rd ed.) suppliers are identified.

• Special arrangements for nonspecific customer requirement suppliers are identified.

• A program timeline, aligned to the organization’s timing, is established from Strategic Intent to Job1.

• A risk assessment has been completed for all high-impact items.

Table 1.1 Typical items of concern in an IRE

Typical risk drivers | Y/N | Expectations | Guidelines |

Are there issues preventing completion of tasks by required date? | A common acceptable scoring is a range of 60–80 and for safety items a range of 70–90. If color is used for evaluating risk the following is recommended: RED: Cannot bid/source business unless a customer director or higher signs off. YELLOW: Requires customer’s senior manager signature for bid approval or sourcing business. GREEN: OK to bid or source business. | Review the planned completion dates for the tasks identified. Remember that the production tooling is complete by the verification of process time milestone. | Since tooling completion affects many APQP deliverables, it is imperative that it be monitored very closely. Late tooling should equate to a high completion after pre-volume production (PVP) and, if possible, it should be an automatic activity. |

Will the production part approval process (PPAP) be completed by the required date? | Review the planned PPAP date. In the review you want to evaluate capacity projections. | If PPAP is not expected to be completed on time, a higher risk level is warranted. If engineering changes are the reason for the projected delay then the PPAP submission Delay (some call it: alarm; Request for Eng. Change and so on). | |

Is the design complete? | The part design/CAD should be complete and attached as part of the original source package. | If the supplier submitted a request for quote (RFQ) to an incomplete or non-existent part there is increased risk to the program. Tooling kickoff (TKO) without a complete design is also a high risk to the program. | |

Has historical design stability been considered? | Review lessons learned (both TGW and TGR) from previous or surrogate programs. Focus on the timing of engineering changes and whether they were minor or major in scope. | A high incidence of change notifications or one major or more than one minor change should reflect a higher risk level. | |

What is the customer impact if the part fails (in any way, or more specifically on issues of safety, application, functionality, etc.)? | Determine the potential customer impact if the part has failed in the past or it fails under the new conditions. Avoidance of any customer perception issues/problems must be a priority. | Parts with a high degree of customer interface should have been identified as high-risk items. Typical items here may be: safety components, appearance requirements for high visibility areas, etc. | |

What is the level of the process technology? Is it old? Widespread? Innovative? | Review the proposed manufacturing process. Make sure all functions are accounted for. | Processes that are using new technologies for the supplier require higher risk levels. | |

Is this a new manufacturing location (Greenfield)? | Manufacturing locations new to a customer must be evaluated and an acceptable score must be attained. All open issues—if there are any—must be closed. In case of any items being open, they must have appropriate overrides and authorization. | A new supplier to a particular customer represents a higher risk to the program since there is no direct history with that supplier, so the designated risk should be higher than for a supplier with some history (Brownfield). | |

Have there been historical quality problems with similar parts? | All historical quality characteristics in reference to a part—if applicable—or surrogate parts must be reviewed and evaluated to ensure these issues have been addressed so that they are not repeated. | Any high incidence for any key characteristic for a particular part represents a higher risk. Repeated issues or lack of corrective actions on any pending issue must be identified as a high-risk part or program. | |

What is the supplier’s pre-assessment scoring method and what are the criteria for success, i.e., Q1 3rd ed. (Ford), Supplier Quality Bid List (SQBL; Fiat Chrysler)? Is there some form of specific score card for the supplier in addition to quality, cost, delivery, performance, risk? Or any other ... |

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- List of acronyms

- Preface

- Author

- Introduction

- Section I: The APQP process

- Section II: Selected specific issues concerning APQP

- Appendix A: Leadership of top management

- Appendix B: IATF 16949

- Appendix C: FMEA forms

- Appendix D: Failure mode avoidance (FMA)

- References