- 320 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

This remarkable book combines simplicity of treatment with depth of coverage and is written in a refreshingly original style. Dispelling the mystique which so often surrounds the subject, and without indulging in complex mathematics, the author explains how to achieve low scrap rates, zero customer rejections and the many other benefits of systematic quality control.

Information

Part I

Quality and the Manufacturing Process

1

The Role of Quality

Quality control is not bolted on to a manufacturing process as an afterthought; at least, it should not be, if it is to be effective. The sad reality, however, is that quite often a manufacturer finds himself in trouble with his customer as a consequence of his failure to build quality into his product and then tries to insert a quality function into a ramshackle system of production. It rarely works. But since this does happen, the problem of how to put a bad quality condition right will be dealt with later on in the book. For the time being let us look at the manufacturing process.

Manufacturing is concerned with one thing, and one thing only – the conversion of resources into income and profit.

All the other activities of the ^manufacturing enterprise – accounting, personnel, purchasing, engineering – are supportive to this resource-conversion process; supportive, not subordinate or submissive.

Four resources are available to the converter:

- raw materials

- machinery

- time

- people

and to be successful in the cruelly competitive world of business a manufacturer must make the fullest possible use of them; they are all that he has. Upon how well, or how badly, these resources are used depends the outcome of manufacturing effort; and using them properly depends on an understanding of their nature.

The four resources

Raw Materials

The raw materials of one conversion process are the finished products of a previous manufacturing process; as such they vary in their attributes and behaviour. There are ‘good’ raw materials and ‘not so good’ raw materials. A ‘good’ raw material is one which meets the needs of your manufacturing process better than another, similar, material.

For example, you might be a glassmaker, buying in specially prepared sand for conversion in your furnace into glass. You buy one grade of sand which is contaminated with traces of impurities such as iron, so your product – glass – instead of being totally colourless (’water-white’) is tinged with green. This is acceptable unless your market demands water-white glass, in which case you are obliged to specify iron-free sand.

Similarly, suppose you are a maker of tin cans: you use the most modern equipment, but the tinplate you use (tinplate is sheet steel lightly coated with metallic tin) has microscopic non-metallic inclusions within the body of the steel sheet. You make your cans, but they split at the top. You are obliged to specify a different grade of tinplate.

Whatever the product of a manufacturing conversion process, only the best raw materials are good enough. Any manufacturer prepared to put up with the problems arising from trying to use a raw material which is less than the best is placing himself at a permanent disadvantage to his competitors. This would be foolish.

But seeing that the best raw material is equally available to all manufacturers competing in the same market, if all are using the best, then none is able to become more competitive than his competitor through his selection of raw material.

So the origin of business competitiveness must lie elsewhere in the conversion system.

Where? In which of the other resources?

Machinery

As with raw materials, there is good machinery, and less than good. The choice of what seems to be the best for any manufacturer to use is a matter of technical judgement, as is the selection of raw material. One thing is true, though, any competitor in any field of manufacturing may be sure that his competitors are unlikely to be buying anything except the best available machinery. Again, if all are buying the best, then none is able to secure any competitive advantage over the other; this must be sought somewhere else.

Time

This resource is free. Though it can be traded, it cannot be amassed. Every one of us has an equal share of it, to be spent either by using or by wasting.

Whenever manufacturing machinery is working it is using time; whenever it is idle it is wasting time. Working for forty hours a week and idling the remaining one hundred and twenty eight represents chronic under-use of available time, which is one of the reasons why some of our most successful manufacturers are those whose plant works around the clock.

Their factories are busy 168 hours a week, effectively reducing the element of fixed assets allocated to the costs of each unit of product. But only 168, not a minute more for anybody. There can be no source of competitive advantage to be gained from the way the resource of time is used when all competitors are working the entire 168 hours available.

So where must competitiveness have its roots?

People

’First, we make people’, said Mr Matsushita, then, we make things.’ And he means it, and acts upon it to devastatingly competitive effect.

It is a truism that no organisation can be better than the sum of the people who comprise it, and the sum of a hundred imbeciles cannot amount to genius.

’Sum’ does not mean the arithmetic sum of the 2 + 2 = 4 kind; thanks to the interactions between people working together it means the ‘synergetic sum’: either the positive synergy of 2 + 2 = 5 or more which characterises high-performance organisations, or the negative synergy of 2 + 2 = 3 or less which arises when organisations fritter away their energies in internal conflict instead of external conquest.

This is where good quality control has its roots.

’Without Labour’, Karl Marx observed, ‘Capital is dead’, which is a way of pointing out that without people the best raw materials are nothing more than unrealised potential, and the finest machinery is nothing more than hardware rusting under a canopy of cobwebs. The conversion of these resources, in the space of available time, happens only because people make it happen, and it is done either wastefully or thriftily according to how incompetent or how skilful are the people doing it. Quality control is concerned with thrift during the process of resource-conversion. Let us look at …

Conversion

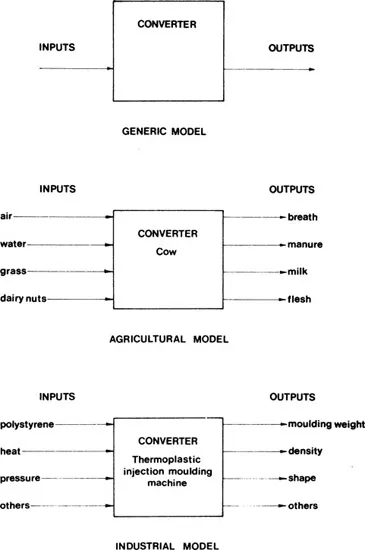

A conversion process can be schematically illustrated, as in Figure 1.1. This shows the generic model of conversion and two examples of specific models, an agricultural model and an industrial model.

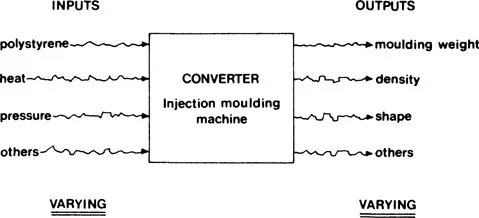

In the ideal manufacturing operation raw material would be so perfect and machinery so flawless that the product would consistently achieve perfection without the need for people to do anything. But perfection is never possible, raw material varies slightly in its behaviour and its properties, power supplies fluctuate slightly, pressures are not absolutely constant, and so on. This variation, which affects all the inputs and gives rise to variation in the outputs is best illustrated on our model of the conversion process in Figure 1.2.

All this is too generalised for its importance to be readily appreciated. But because this is where the final quality of the product is initially determined, we must examine it in greater detail.

Let us take an example from the real world of manufacturing and use it to illustrate truths about all manufacturing process quality. As good an example as any is

Figure 1.1 Schematic Picture of Conversion Process

the way in which plastic objects, which proliferate in our civilisation, are made. Using this example will enable us to see how quality control is applied to the manufacturing process in order to make the most profitable use of resources. All that is learned from the ‘plastic’ example will be just as applicable to any other manufacturing technology.

Figure 1.2 Schematic Picture Showing Inputs Varying and Outputs Varying in Response

The Conversion of Plastic Materials

’Plastic’ is short for ‘thermoplastic’. A thermoplastic material softens and mel...

Table of contents

- Cover

- Half Title

- Title

- Copyright

- CONTENTS

- Foreword

- Preface

- Acknowledgements

- List of illustrations

- Part I: QUALITY AND THE MANUFACTURING PROCESS

- Part II: QUALITY AND PEOPLE

- Appendix of standard procedures

- Sources of further information

- Glossary

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Right First Time by Frank Price in PDF and/or ePUB format, as well as other popular books in Business & Business General. We have over one million books available in our catalogue for you to explore.