![]()

Chapter 1

The Lean Business Delivery System

The Lean Business Delivery System (LBDS) is an ongoing journey in the pursuit of waste elimination and error reduction. When you finally make the decision to embark on a Lean journey or you decide to restart your Lean journey, you must realize and be willing to admit how little you may actually know about your processes or how to improve those processes. Remember, the problems you have today are the result of changes you, or someone, made in the past and these are the most difficult to change. You must abandon the old way of thinking and doing things, along with the results-based management style. This old reactive management approach adds variation up and down the organization, and results in endless work-arounds, ultimately creating metrics and reports back telling you what you want to hear, not what you need to know.

A key concept in Lean is to avoid batching and focus on one-piece flow. In many cases this might seem counterintuitive; however, this main principle is very important to understand if you want to achieve success. Batching environments are fraught with waste, lack of space, frustrated employees and customers, ongoing delays, and limited control over your processes. Once you start Lean:

1. Space, which seemed initially to be at a premium, becomes available, resulting in “excess” space.

2. Results can be obtained quickly within a specific area or process.

3. Root-cause analysis and management by fact will solve the problems. This includes ingraining a philosophy of fixing the process to avoid reoccurrence.

4. Realization that by focusing on improving the process, return on investment (ROI) will take care of itself. Companies that truly comprehend Lean don’t focus on ROIs.

5. You must create an environment of respect and caring for people. Should blue-collar employees make less than white-collars?

6. For CEOs, patience and perseverance is the key. Executive leadership must drive the culture change, adoption, and deployment.

Lean processes can be applied anywhere, even at home. Any process can be improved by applying Lean tools. Results will be direct cost savings and significant cost avoidance. We define cost savings as those that directly hit the bottom line, whereas cost avoidance refers to items that would have increased costs had we not alleviated the need for them. The elimination of waste in a process will decrease the process steps and reduce the opportunities for errors, thereby improving customer satisfaction and, ultimately, quality.

Implementing Lean requires a counterintuitive paradigm shift in thinking to offset the ever-prevalent resistance to change from the current system. This requires an ongoing shifting of attitudes during the transition from the old batch business model. This includes the need to adopt new accounting techniques and typically requires significant structural organizational changes; in short, developing a new way of thinking.

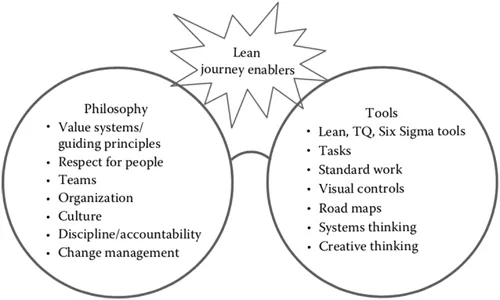

A consistent theme throughout this book (see Figure 1.1) is the balance required between philosophy and tools. As such, about 50% is based on Lean tools, system thinking, and practical application, while the other 50% is associated with value systems, strategic thinking, creative thinking, respect for people, change management, leadership, and sustaining the Lean culture. This overall theme, while not always stated, is underlying every chapter and is referred to interchangeably in different ways (i.e., tasks vs. people, tools vs. people, etc.).

Figure 1.1 Balance between philosophy/people and tools. (Source: Protzman, Charles. The Lean Practitioner's Field Book. Productivity Press.)

An integrated framework is required to ensure that Lean initiatives are successful. The components for this integrated structure include:

■ Visual management

■ Product, information, and material flow

■ Management process (leadership)

■ Measurable targets

■ Standards

■ Process focus

Leaders must experience and see problems firsthand by going to the floor, as you can’t fix problems with PowerPoint™ presentations. The CEO must provide the unwavering commitment to Lean by leading by example, participating in kaizen events and driving a continuous improvement culture. The CEO must dedicate the time to truly understand how to develop and create a Lean culture.

The CEO must lead and drive Lean, utilizing their best resources to obtain the best results as the Lean journey takes a tremendous amount of training and perseverance and sometimes brute force to implement. Trust and respect with all employees is important and management must embrace transparency and openness.

Seeing and eliminating waste becomes how everyone in the organization does business. Companies with complex systems generate both systemic-type results and problems. Each part of the process is interdependent on the others. The problems need to be approached with systems-thinking tools; however, most employees are never trained in systems thinking. Systemic problems are exacerbated by functional and some matrix types of organizations. One cannot change small pieces of a system and expect the overall system to change; therefore, the only way to fix problems is to change the systems.

Lean Definition

On the Lean Enterprise Institute (LEI) website, Lean is described as the five-step process for guiding the implementation of Lean techniques, which is easy to remember but not always easy to achieve:

1. Specify value from the standpoint of the end customer by product family.

2. Identify all the steps in the value stream for each product family, eliminating waste whenever possible, as those steps do not create value.

3. Make the value-creating steps occur in tight sequence to ensure the product flows smoothly toward the customer. Ensure the process steps flow without going backward.

4. As flow is introduced, let customers pull value from the next upstream activity.

5. As value is specified, value streams are identified, wasted steps are removed, and flow and pull are introduced. Begin the process again and continue it until a state of perfection is reached in which a perfect value is created with no waste.

Leveraging the Lean Business Delivery System (LBDS) for Continuous Improvement

A key to success and to understand Lean at the core is to commit to one-piece flow. Our innate desire to batch wherever possible is always fighting Lean thinking. Batching is a system and batching systems are fraught with batching problems.

A major change in management thinking is required. Managers must be taught that everything we do is part of a system. This is known as “systems thinking.” Everything is interconnected. All the problems you have today are a direct result of the systems you have in place. It is important to realize you are, in fact, rewarding these ongoing behaviors and problems.

Gone are the days of the results-based management style, which drives wild and crazy behaviors. Instead, we must convert to a process-focused management style. Challenge your workforce to focus on solving problems at the source to ensure the problems never come back. This difference in management-style approach directs us away from the “shoot-from-the-hip” mentality, which adds variation throughout the organization, and results in endless work-arounds. Your business cannot survive when the system creates metrics and reports telling you what you want to hear, versus what you need to know.

What Is LBDS?

A “Lean Business Delivery System” supplies the best value to the customer all the time, with the highest quality, at the lowest possible cost. This requires creating a culture of continuous improvement and an environment where everyone in the organization participates in eliminating waste and streamlining processes to supply the best value to the customer.

LBDS: Roots Are Actually in the United States

Lean is typically called a Japanese production system. Most people think of the Toyota Production System (TPS); however, many people are surprised to learn the TPS model actually has its roots in the United States. TPS is based on an American system, which Toyota has been working on perfecting. In its simplest form, it is based on the following five parts, which we will explore throughout this book:

1. The Henry Ford assembly line but modified for high-mix low-volume production.

2. The American supermarket replenishment system: just in time (JIT)

3. Total company-wide quality control.

4. Setup reduction.

5. Participative management.

While Henry Ford developed the concept of single-piece flow, it was actually Charles Sorenson1 who determined how to implement the assembly-line process. Sorenson was the production manager who worked for Henry Ford and who later determined how to produce a B24 airplane every hour. He accomplished this from starting up a greenfield plant in Willow Run during World War II (WWII). Within two years it went from dirt to flying airplanes. Most of what we know as Lean today can be attributed to Henry Ford, who also introduced concepts such as job rotation, machines to do boring or dangerous work, the concept of continuous improvement (kaizen), and the idea there is an advantage to constantly working to reduce your pricing (and costs) while increasing wages, the creation of a suggestion system, and much more.2

Setup reduction can be traced back to the early 1900s; however, many of the Lean concepts we have today originated much earlier, some say even with the Egyptians or Romans. The roots of standard work started with a US Government Wartime Program developed during WWII called “Training Within Industry” (TWI) taught to the Japanese in 1951. Total Quality (TQ) and participative management were taught to the Japanese by the Civil Communications Section (CCS) in 1948 and 1949 as part of a daily—half a day—eight-week training course in American Management. It was the CCS, comprised of the three wise men from the United States, Frank Polkinghorn, Homer Sarasohn, and Charles Protzman Sr., that recommended follow-up with visits by...