![]()

Chapter 1

A Meeting in the Parking Lot: Lean and Creative Problem Solving

Carlo pulled into the parking lot of Global Plumbing Supply just before the rain started. The weather forecaster on the radio had waxed eloquently about the incoming line of storms, and Carlo had made a mental note – and several physical notes – to remember an umbrella. But now, as he glanced around the front and back seats of his car, it was clear that the umbrella hadn’t left the house with him that morning. This was no light spring shower, and there were at least 50 yards between his parking spot and the building entrance. Carlo checked his phone. He had 10 minutes before his meeting started, but there was no indication that rain was going to lighten up.

Carlo was about to make a dash to the door when a grey Toyota pulled into the space next to his car. Looking over, he saw his friend and coaching colleague, Linda. He knew that this engagement at Global Plumbing Supply was an unusual one, and that he would be sharing coaching responsibilities with another coach, but he hadn’t realized it might be Linda. “All right,” he said to himself, “this is a great development!” He was even more delighted when he saw that Linda was getting out of the car carrying a large umbrella. “Hey, Linda!” he greeted her.

“Carlo, nice to see you!” she replied. “Want to share my umbrella?” Inside the lobby of Global Plumbing Supply, they introduced themselves to the receptionist. “I see you both are expected by Brandon Go, the CEO,” replied the receptionist. “Mr. Go called and said he was delayed for 30 minutes or so. He sent his apologies and asked if you could wait for him. Please make yourselves comfortable here in the lobby.”

Carlo and Linda chose a couch in the small waiting area. “This looks like a great time to catch up,” said Carlo, taking off his jacket, “and to talk about this project.”

“How did you get involved in this?” asked Linda.

“I got a call from a friend of mine who told me that this company was looking to improve their ability to innovate, and that she had recommended me as creativity coach for their executive team. I have to say I was surprised to get the call, as I had heard that Global Plumbing Supply had been starting a lean deployment, and as much as I admire the kind of stuff you do, I have never had a company that is deploying lean also ask about creativity.”

Linda chuckled. “That might be the case, but maybe we can change things with this project. I was the one who suggested to Brandon that we build creative thinking into this lean deployment because I’m finding that my clients struggle with the kind of deep thinking that lean requires.” She handed Carlo an envelope. “Here is a briefing about GPS, and some background about the lean deployment. Look at it later. I’m glad you’re on board. It is going to be fun to work together at last!”

“I never thought when we took that class together that we might work together some day,” said Carlo. “I mean, lean thinking and creative thinking are really almost polar opposites.”

Linda raised an eyebrow. “Carlo, how much do you know about lean thinking?”

“To be completely honest, not a lot. I know it is about quality control and manufacturing, standardization, things like that. Important, but not necessarily creative.”

Linda raised the other eyebrow.

Carlo caught her look. “But since we seem to have some time on our hands, and since we’re going to be working with each other, I think I need to learn more.”

“As I do about creative thinking,” replied Linda. “Although I know enough to recommend you join this project!”

“I’m ready to listen,” said Carlo, “if you’re ready for my questions. Pretend I don’t know anything (which wouldn’t be too far off). What is lean thinking?”

“Thanks for asking,” Linda replied. “Everyone who is involved in lean in some way has their own preferred definition and visual model. You can think of this as Linda’s definition of lean and lean thinking. I define lean as a socio-technical system for developing and managing people in organizations so that they can solve problems and continuously improve the organization to deliver value to customers. Lean is modeled on the business practices of Toyota and other organizations that have pursued ‘lean.’ Practicing lean results in reduction of waste and increased customer satisfaction.”

“Hold on a moment,” said Carlo, who was taking notes. “I know something about socio-technical systems, but how are you defining that?”

“Good question,” Linda replied. “I tell people this: ‘Socio-technical’ means that lean involves people and their interactions, as well as technical tools. How people work with each other, coach each other, listen to each other, respect each other, and especially develop each other is critical to lean. And …” Linda paused, reflecting on something.

“And?”

“And the funny thing is, we’re often taught the technical side of lean long before the people side is elucidated. In my lean training, the first this I was taught was 5S, a tool for workplace organization. It was only later in my career that I realized the real purpose of the tool was to give managers the opportunity to develop their employees to be able to solve problems that interfered with having materials always ready. I totally missed the point for about five years.”

“Why do you think that was?” asked Carlo.

“I’m not completely sure, although I believe it is partly because people (and that includes me) like to have easy answers, and don’t always want to think too deeply. Or we’ve been conditioned to think that we’re not expected to think deeply at work – we should focus on getting work done. But I came to realize that what I was studying and practicing and eventually teaching wasn’t just ‘lean’.” Linda made air quotes as she said “lean.” “What it really was, was ‘lean thinking.’”

“Which is?”

“Lean thinking is the thinking style of people who have been developed in a lean organization to see and solve organizational problems to deliver value to customers. Lean thinking can be learned and developed. And then I came to this realization: that the purpose of a lean system, is not to ‘reduce waste’ or ‘improve flow of value to the customer.’”

“It’s not?” asked Carlo.

Figure 1.1 The Purpose of the Lean System.

“Not at all. The purpose of the lean system is to develop people who can reduce waste and improve the flow of value to the customer.”

“And then I realized, it doesn’t matter what business someone is in. Whether someone develops software, works in a bank, makes automobiles, teaches high school students,” Linda looked around the lobby, “even if they run a plumbing supply company. They can use lean tools to improve their organization. But they won’t do anything sustainable until they start to develop people to be lean thinkers.”

“And who are lean thinkers?”

“Lean thinkers are people who can see and solve problems. They may be good at using lean tools, or they may never use a ‘lean tool.’ What they excel at is using the scientific method to make observations about problems that need to be solved, create hypotheses on the root causes and solutions, test the solutions, and implement them.”

“You know,” said Carlo, “this is fascinating to me. My work is all about solving problems, especially problems that require innovative solutions. I can see now why you wanted to include creative thinking in this work. But I use a very specific problem-solving methodology, which I suspect is not the same one used in lean thinking. Tell me about how you solve problems as a lean thinker.”

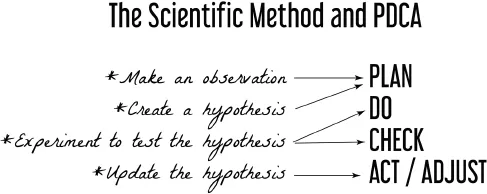

“The lean problem-solving process is basically the scientific method: make an observation, create a hypothesis, do some experiments to test the hypothesis, and update the hypothesis based on the results of the experiments. We capture this process as ‘Plan-Do-Check-Act.’”

Figure 1.2 The Scientific Method and PDCA.

Carlo snapped his fingers and leaned forward. The receptionist looked over to see what was going on. “Oh sorry,” Carlo said to the receptionist. “I got a little over-excited here.” He turned back to Linda. “PDCA, isn’t that the Deming cycle? I have heard of that.”

“That’s right,” Linda replied. “Except W. Edwards Deming called it the Shewhart cycle. But what’s important is that a lean thinker is always learning how to perform PDCA better. All the lean tools were developed and improved using PDCA.”

The receptionist called out to them. “Mr. Go is ready to see you now. Do you need directions?”

“I know my way,” said Linda. “Come on, Carlo, I think you’re going to like Brandon.”

They walked down a hallway and into an office area. A man in his mid-thirties was walking toward them with his hand outstretched. “Linda, great to see you. So sorry I had to keep you waiting. And this must be Carlo. I’m really looking forward to meeting you and learning about creative thinking. Linda speaks very highly of you!”

Brandon’s office was not what Carlo expected for a CEO’s office. They sat at a conference table; there was no desk. The office was small, and there were boxes of plumbing parts stacked in one corner.

Brandon spent a few minutes reviewing Global Plumbing Supply’s history. He had inherited the company from his parents, just when he was about to start his MBA program. Since his parent’s unexpected deaths, he had built the company from a regional to a national supplier, with significant increases in revenue. But as the company had grown, silos had developed, costs had increased, and while income continued to be strong, the operating margin had dropped precipitously. They had started to move the company from paper-based to digital processes, but that seemed to result in more rather than fewer problems. In the middle of this situation, Brandon had read a book about lean that he had picked up while delayed in an airport. “That was the best travel delay of my life!” he exclaimed. He had hired Linda’s company to help GPS s...